-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

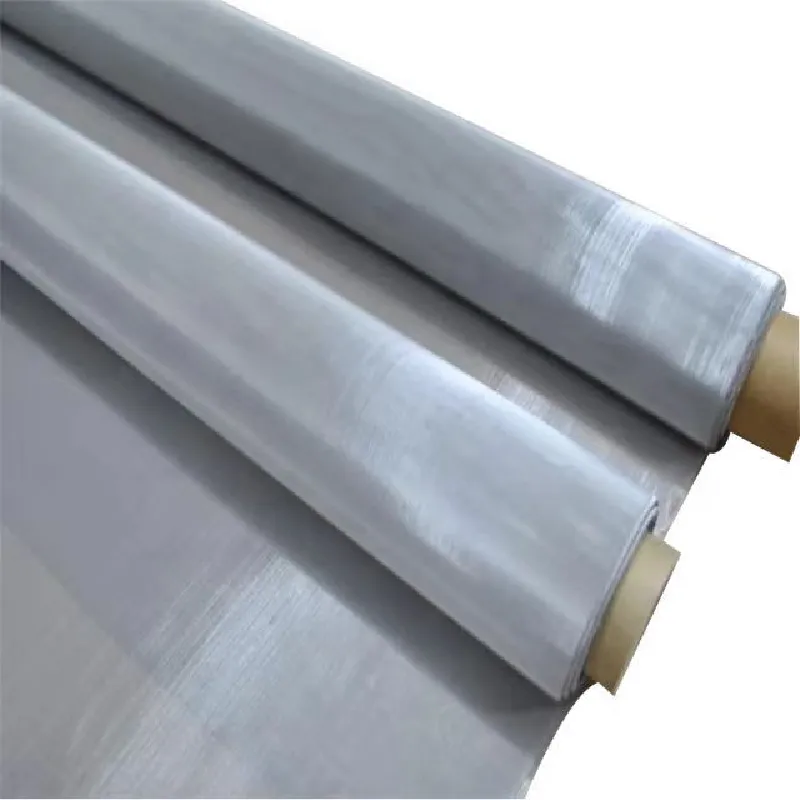

concrete steel wire mesh

The Importance and Applications of Concrete Steel Wire Mesh in Construction

Concrete is a staple in the construction industry, known for its strength, durability, and versatility. However, to enhance its performance and prevent cracking, the integration of steel wire mesh has become an essential practice. This combination not only increases the structural integrity of concrete but also widens its applications in various construction projects.

What is Concrete Steel Wire Mesh?

Concrete steel wire mesh is a grid-like structure made from interconnected steel wires. It is designed to be embedded within concrete during the pouring process. The mesh typically comes in sheets or rolls and is available in various sizes and wire gauges, depending on the specific requirements of the project. The primary function of steel wire mesh is to provide tensile strength, which concrete lacks. While concrete is incredibly strong under compression, it is much weaker when pulled or bent. The wire mesh compensates for this deficiency by distributing loads evenly throughout the structure, thus preventing cracks and ensuring longevity.

Benefits of Using Steel Wire Mesh in Concrete

1. Crack Control One of the main advantages of using steel wire mesh is its ability to control cracking. Concrete can shrink and expand due to temperature changes and drying, leading to cracks. The wire mesh mitigates this risk by providing reinforcement that holds the concrete together and redistributes stresses.

2. Increased Load-Bearing Capacity The incorporation of steel wire mesh boosts the load-bearing capacity of concrete elements. This is particularly important in structural applications where safety and reliability are paramount. The reinforcement allows for thinner slabs or less dense concrete, effectively saving materials without compromising strength.

3. Versatility in Application Steel wire mesh is used in various construction projects, including floors, walls, pavements, and bridges. It is particularly beneficial in pavements, where constant traffic can lead to surface degradation. By reinforcing these surfaces, the longevity of roads and walkways is drastically improved.

concrete steel wire mesh

4. Cost-Effectiveness While an upfront investment in steel wire mesh may seem significant, it ultimately leads to lower maintenance and repair costs. Structures that incorporate quality reinforcement are less likely to suffer from extensive cracking or structural failures, resulting in reduced long-term expenses.

Applications in the Construction Industry

Concrete steel wire mesh is widely used across different sectors of the construction industry. Here are some primary applications

- Residential Construction Steel wire mesh can be utilized in foundations, driveways, and patios to ensure stability and durability. Homeowners benefit from reduced maintenance needs over time, as these structures are less prone to cracking.

- Commercial Buildings In larger structures like office buildings and shopping malls, using steel wire mesh in floors and walls allows for significant spans without the need for excessive support columns, maximizing usable space and aesthetic appeal.

- Infrastructure Projects For projects such as bridges and overpasses, steel wire mesh provides crucial support, enhancing the safety and reliability of these critical structures. They can endure heavy loads and withstand harsh environmental conditions.

Conclusion

In summary, the integration of concrete steel wire mesh in construction is a game-changer for enhancing the performance of concrete structures. With its ability to control cracking, increase load capacity, and reduce long-term maintenance costs, it is invaluable across various applications, from residential projects to large infrastructure developments. As the construction industry continues to evolve, incorporating innovative materials such as steel wire mesh will be crucial in creating resilient and sustainable structures that meet modern demands. Investing in quality reinforcement not only ensures safety and durability but also promotes efficient use of resources, paving the way for a more robust construction future.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025