Debris Netting – Heavy-Duty, UV-Stabilized Scaffold Safety

Field Notes on Debris Netting: What Pros Really Use and Why

If you’ve walked past a busy jobsite lately, you’ve probably seen bright panels of Debris Netting breathing slightly in the wind. Simple kit, huge impact. I’ve specced it on high-rises, event scaffolds, even shipyards. And—surprisingly—what looks like “just net” hides a lot of engineering and, frankly, a few myths.

What’s in the roll

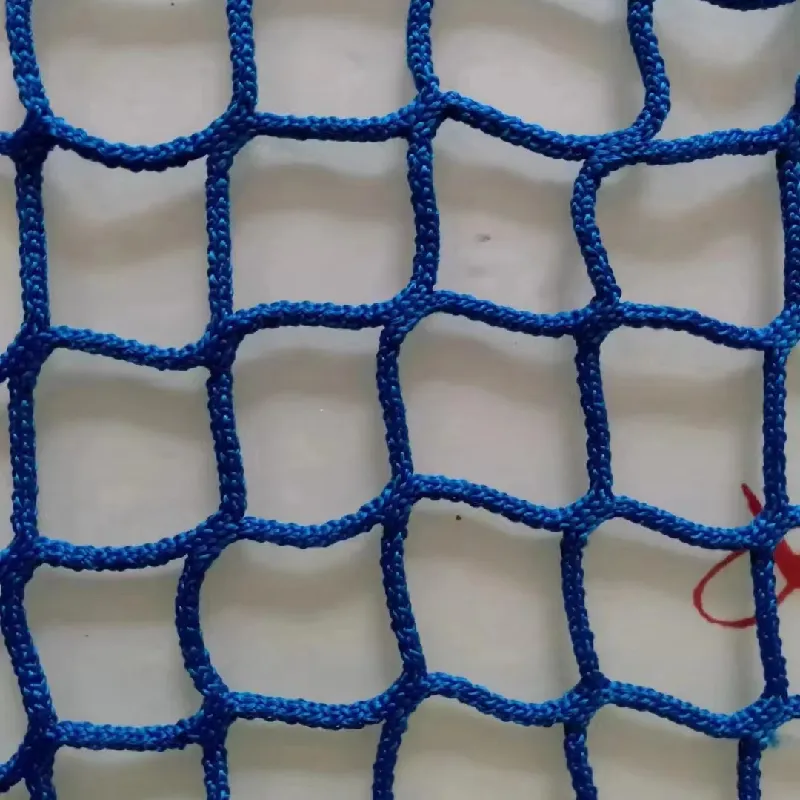

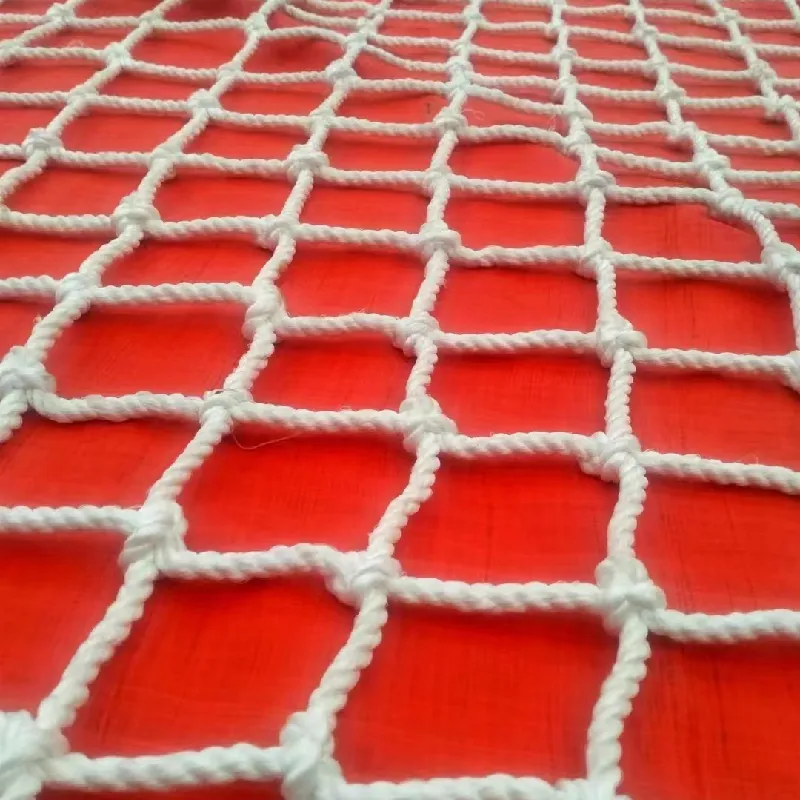

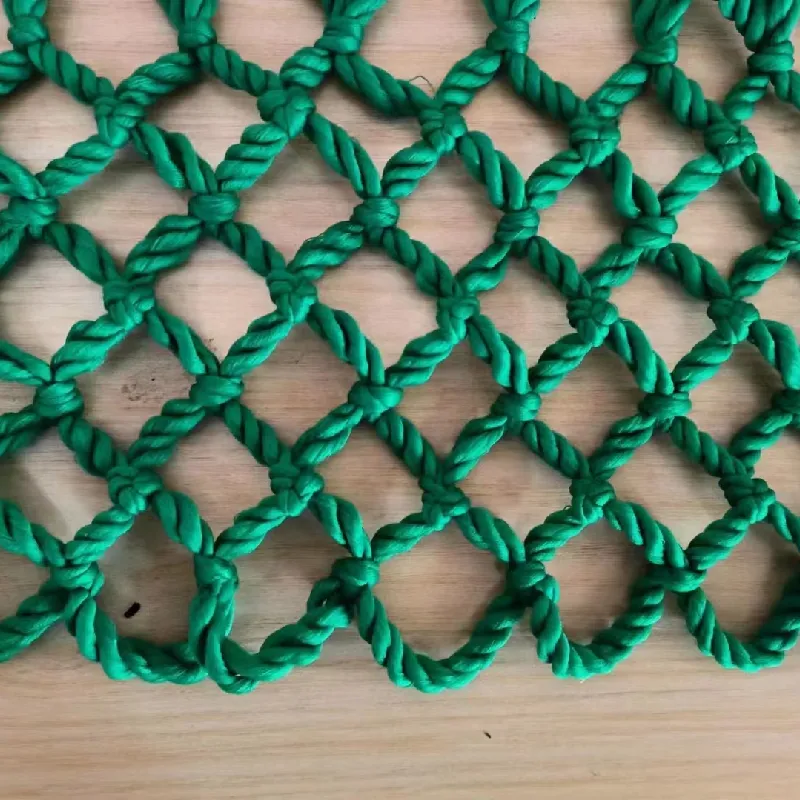

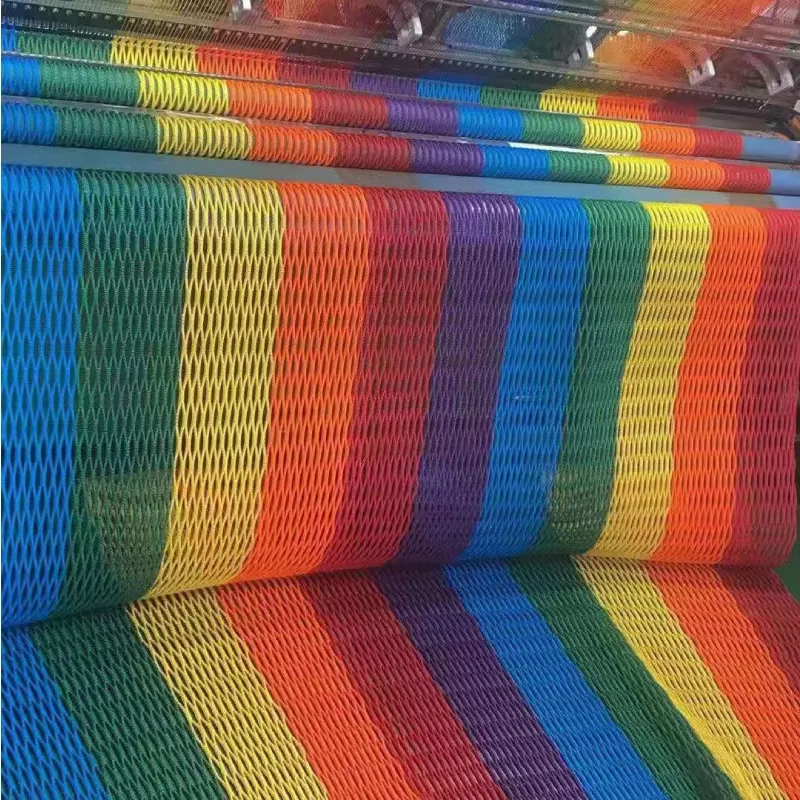

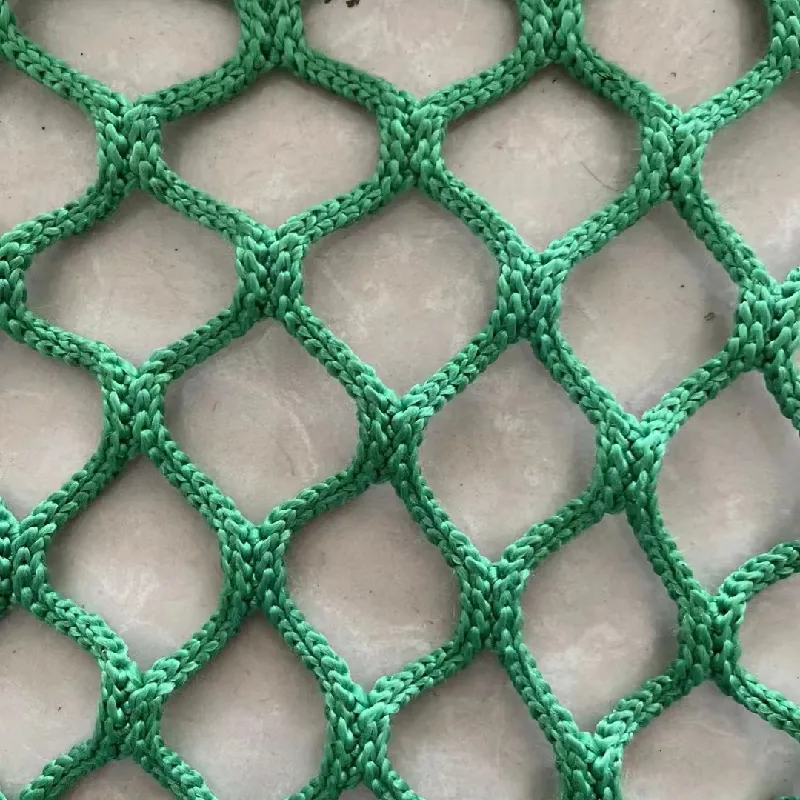

Product spotlight: Safety Net from China-based YJ Wire Mesh. Material options include polyester, elastic yarn, and high‑strength yarn. Mesh options: 3 cm (≈4 mm rope), 5 cm (≈5 mm rope), 10 cm (≈6 mm rope). In practice, tighter mesh for façade work and fine debris; larger mesh for perimeter catch and ventilation. To be honest, most buyers lean to 5 cm—it’s a good balance.

Specs at a glance

| Item | Typical Range | Notes |

|---|---|---|

| Material | Polyester / elastic / high‑strength yarn | UV-stabilized options |

| Mesh size | 3 cm, 5 cm, 10 cm | Choose by debris size & airflow |

| Rope thickness | ≈4–6 mm | Core/cover construction varies |

| Colors | Green, black, orange (others on request) | Visibility vs. glare trade‑off |

| Service life | ≈3–5 years | Real-world use may vary with UV/chemicals |

Process flow that actually matters onsite

- Materials: UV-stabilized polyester or blended high-strength yarns.

- Methods: Twisted/knotted or knotless mesh, heat‑set; border rope stitched/overlocked.

- Testing: EN 1263‑1/2 methods for safety nets; ISO 1806 mesh break test; NFPA 701 flame; UV aging (ASTM G154) in some QA labs.

- QC checkpoints: Mesh size, knot strength, edge-rope strength, label traceability.

- Industries: Construction, shipbuilding, logistics yards, stadium/event scaffolds, agriculture windbreaks.

Compliance, test data, and certifications

On reputable lines, border rope strength targets follow EN 1263‑1 guidance (edge rope often specified ≈≥30 kN). Mesh cord break per ISO 1806 is commonly validated in the 1.5–3.0 kN band (product and design dependent). Flame resistance is often checked to NFPA 701 for temporary works where ignition sources exist. Many customers ask about OSHA—installation must meet OSHA 1926.502(c) where safety nets are part of fall protection systems; for debris only, it’s typically used alongside compliant guardrails/scaffolds.

Where Debris Netting excels

- Perimeter containment on scaffolds and slabs.

- Façade work: tool and material fall arrest (lightweight class).

- Public protection around renovations—actually, PR value is underrated.

- Temporary storage racks and mezzanines in warehouses.

Customization (the quiet ROI)

Edge borders, eyelet spacing, flame-retardant additives, branded colorways, even QR-coded traceability tags. I guess the sleeper is pre‑sewn keder edges for fast zip-rail installs—saves crew hours.

Vendor snapshot

| Vendor | Origin | Certs/Standards | Lead time | Customization | Price band |

|---|---|---|---|---|---|

| YJ Wire Mesh (Safety Net) | China | EN 1263‑1/2, NFPA 701 (on request), ISO 9001 | ≈2–4 weeks | High | Value |

| Global Brand A | EU | EN 1263, CE (where applicable) | ≈3–6 weeks | Medium | Premium |

| Regional Distributor B | US | OSHA-use guidance, NFPA 701 | Stock-dependent | Low–Medium | Mid |

Mini case study

A coastal façade project swapped tarps for Debris Netting with 5 cm mesh and FR treatment. Wind loads dropped, crews stopped “sailing” the scaffold, and neighbors—no kidding—sent thank‑you notes about less dust. Site safety logged zero debris strikes in 4 months. That’s the job you want to report upstream.

Installation tips I keep repeating

- Use rated tie cords; keep attachment spacing tight per engineer’s plan.

- Label and inspect quarterly; retire UV‑chalked or cut panels.

- For fall-protection use, follow an engineer’s calc and OSHA 1926.502(c) strictly.

Bottom line

Pick mesh size by hazard, insist on documented testing, and don’t skimp on edge-finishing. The right Debris Netting saves time, lowers neighbor complaints, and—frankly—keeps you out of incident reports.

References

- OSHA 29 CFR 1926.502(c) – Fall Protection Systems Criteria and Practices: https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.502

- EN 1263‑1/2 Safety nets (CEN) – Requirements and Test Methods (publisher info): https://standards.cencenelec.eu/

- ANSI/ASSP A10.11 – Safety Requirements for Safety Nets (overview): https://www.assp.org/standards/a10-11

- NFPA 701 – Standard Methods of Fire Tests for Flame Propagation of Textiles: https://www.nfpa.org/

- ISO 1806 – Fishing nets — Determination of mesh breaking force: https://www.iso.org/standard/58381.html

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025