-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Debris Netting: Heavy Duty Safety & Security for Construction

In the dynamic landscape of modern construction and industrial operations, safety is not merely a regulation; it's a foundational principle. As projects ascend to greater heights and encompass more complex environments, the risk of falling objects and personnel has never been more pronounced. This is where debris netting emerges as an indispensable safety solution. Designed to prevent the accidental displacement of construction materials, tools, and other potentially hazardous items, as well as providing fall protection, debris netting ensures a secure environment for workers and the public alike. This comprehensive guide delves into the world of debris netting, exploring its technical prowess, diverse applications, and why it's a critical investment for any forward-thinking enterprise.

Industry Trends and the Growing Demand for Advanced Debris Netting

The global construction industry is experiencing rapid growth, projected to reach a value of over $15 trillion by 2030, according to PwC. This expansion, coupled with increasingly stringent safety regulations from bodies like OSHA (Occupational Safety and Health Administration) and local authorities, is driving an unprecedented demand for robust and reliable safety solutions. The market for debris netting, particularly heavy duty debris netting and specialized security netting, is expanding significantly. Innovation is focused on enhanced material durability, UV resistance, flame retardancy, and ease of installation, reflecting a shift towards more sustainable and efficient safety protocols. The emphasis is no longer just on compliance, but on creating inherently safer job sites, minimizing downtime, and reducing potential liabilities from falling objects or personnel.

Understanding Debris Netting: More Than Just a Barrier

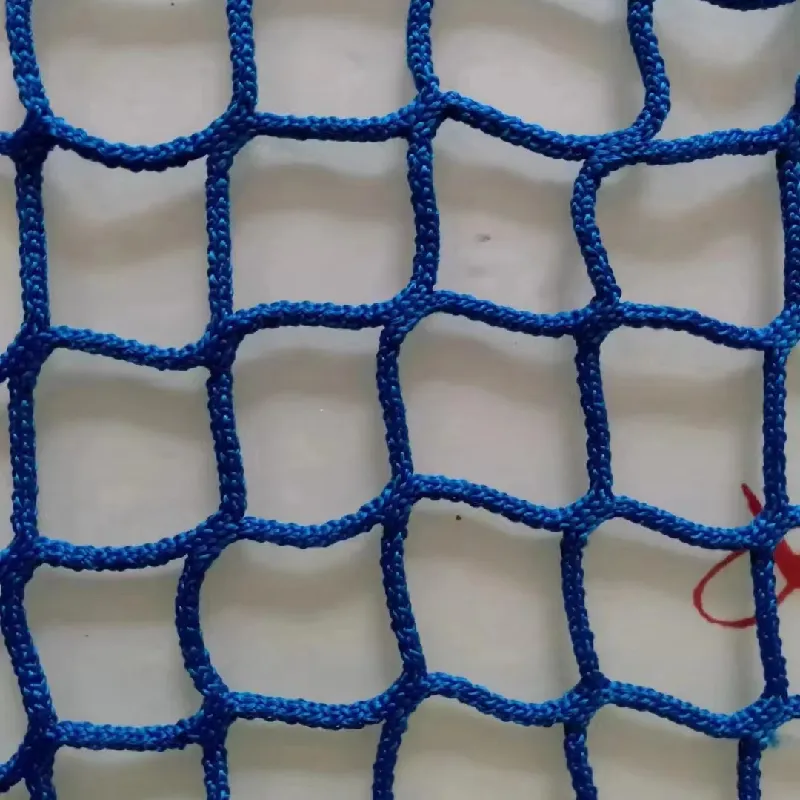

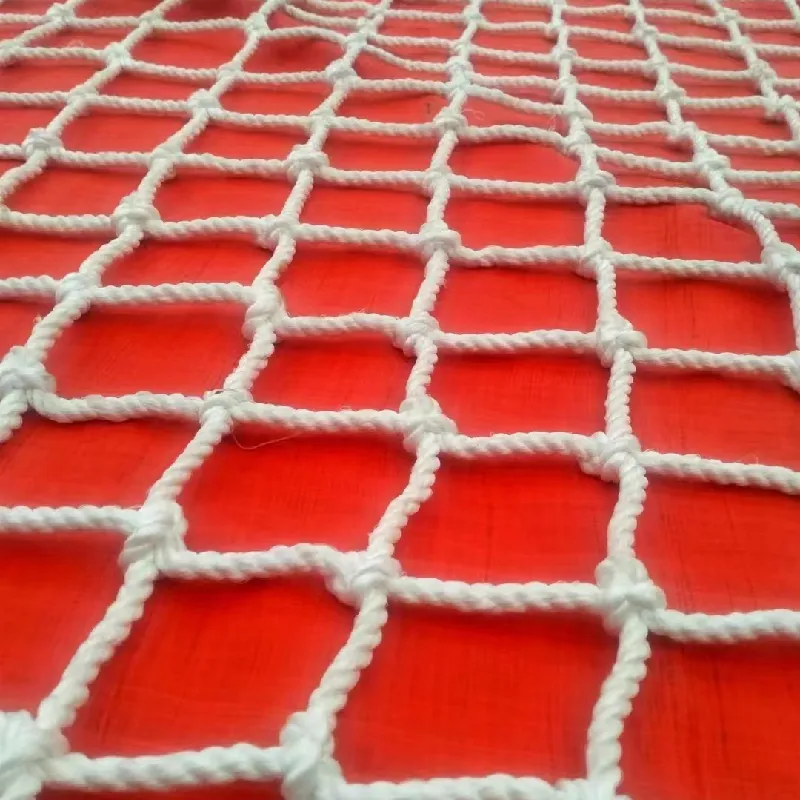

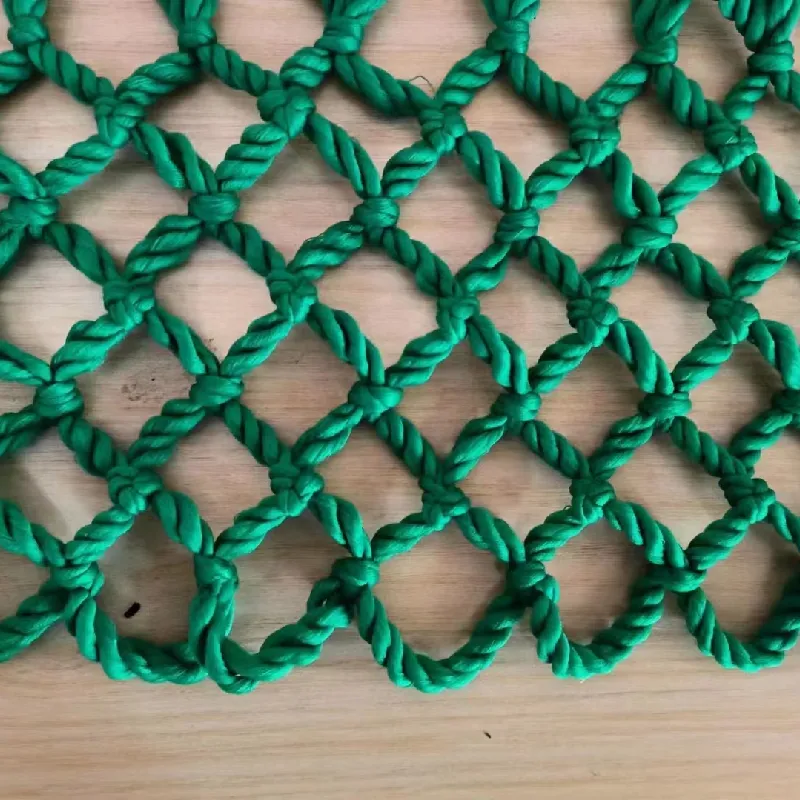

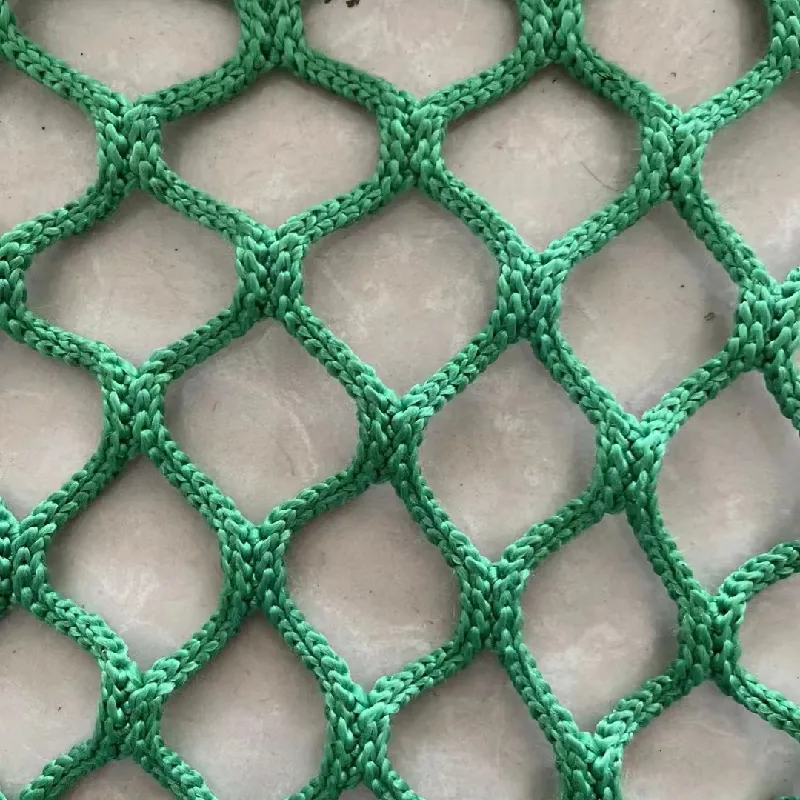

Debris netting, often referred to as scaffold netting or safety netting construction, is a specialized type of protective mesh designed to contain small debris, tools, and other light materials from falling from elevated work areas. While its primary function is containment, modern netting solutions often serve multiple purposes, including providing a visual barrier, reducing wind penetration on scaffolding, and offering a degree of fall protection for workers. The material typically used for high-quality debris netting is high-density polyethylene (HDPE) due to its exceptional strength-to-weight ratio, UV resistance, and chemical inertness. Polypropylene (PP) is also used for specific applications, known for its flexibility and resistance to fatigue. The weave pattern (often knitted or woven) and mesh size are critical factors determining the netting's effectiveness in retaining different sizes of debris while allowing air and light to pass through.

Key Technical Parameters of Debris Netting

Understanding the technical specifications of debris netting is crucial for selecting the right product for your project. Here’s a detailed breakdown:

| Parameter | Description | Typical Range / Specification | Significance |

|---|---|---|---|

| Material | High-Density Polyethylene (HDPE) or Polypropylene (PP) | 100% Virgin HDPE with UV stabilizers | Ensures durability, strength, and resistance to environmental degradation. HDPE offers superior UV stability and tensile strength. |

| Weight (GSM) | Grams per Square Meter | 50 GSM to 300 GSM (e.g., 80 GSM for standard debris, 200+ GSM for heavy duty debris netting) | Higher GSM indicates denser material, greater strength, and often better debris containment capabilities. |

| Mesh Size | Opening size of the netting weave | 1mm x 1mm to 10mm x 10mm (e.g., 2mm x 2mm for fine debris, 5mm x 5mm for larger items) | Determines the size of debris it can effectively contain. Smaller mesh for fine particles, larger for general containment. |

| Tensile Strength | Maximum stress the material can withstand before breaking (MD/CD: Machine Direction/Cross Direction) | Typically ranges from 300 N to 1000 N per 5cm width (ASTM D638, D5034 standards) | Critical for assessing resistance to tearing and ability to absorb impact from falling objects. |

| UV Resistance | Ability to withstand degradation from ultraviolet radiation | Stabilized for 3-5 years minimum outdoor life (e.g., tested per ASTM G154/G155) | Essential for longevity, especially in outdoor applications. Prevents brittleness and premature material breakdown. |

| Fire Retardancy | Ability to resist ignition and slow flame spread | NFPA 701, California Title 19, or equivalent standards | Crucial for safety in high-risk environments, preventing fires from spreading rapidly. |

| Reinforced Edges | Integrated border for added strength | Buttonholes, eyelets, or reinforced hems every 4-6 inches | Facilitates secure attachment to scaffolding or structures, distributing load evenly and preventing tearing at attachment points. |

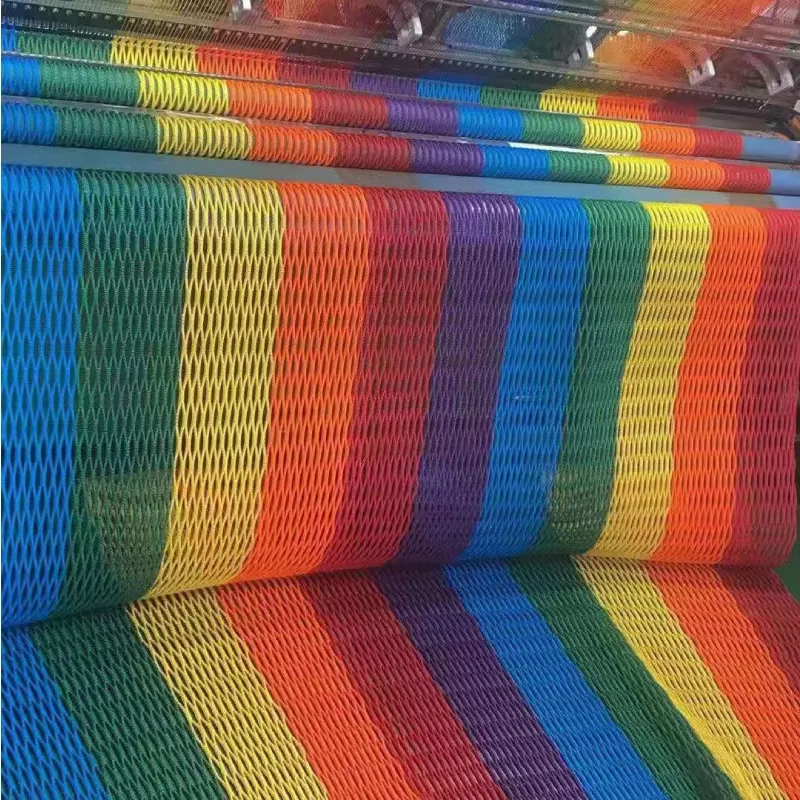

| Color Options | Variety of available colors | Green, Black, Blue, Orange, White | Mainly aesthetic or for specific site identification, though lighter colors may reflect more heat. |

The Meticulous Manufacturing Process of High-Quality Safety Netting (Debris Netting)

The production of durable and effective debris netting is a precise and technologically advanced process, ensuring the final product meets stringent safety standards. Unlike traditional metal fabrication (casting, forging, CNC machining), netting manufacturing relies on sophisticated extrusion and knitting/weaving techniques. The process typically involves:

- Raw Material Selection & Preparation: High-grade virgin HDPE (High-Density Polyethylene) granules are selected. Crucially, UV stabilizers and, for specific applications, flame retardants, are carefully compounded into the polymer mix. This initial step is vital for the netting's long-term performance, especially its resistance to degradation from sunlight and its fire safety properties.

- Extrusion of Monofilaments/Tapes: The prepared polymer mixture is fed into an extruder, where it is melted and forced through a die to create continuous strands (monofilaments) or flat tapes. The diameter of the monofilament or the width and thickness of the tape are precisely controlled, as these directly influence the final netting's strength and mesh density.

- Knitting or Weaving:

- Knitted Netting: This is the most common method for debris netting. High-speed warp knitting machines interlock the monofilament strands into a stable, ladder-resistant mesh structure. This 'Raschel' knitting process creates a netting that, even if cut, resists unraveling, enhancing its durability and safety performance. This is particularly important for scaffold netting.

- Woven Netting: Less common for standard debris netting but used for some heavy duty debris netting or specific security netting applications, where warp and weft threads are interlaced at right angles to create a robust fabric.

- Heat Setting & Finishing: The knitted or woven fabric undergoes a heat-setting process. This stabilizes the mesh, preventing shrinkage or stretching and ensuring consistent mesh size. It also enhances the netting's dimensional stability and overall structural integrity.

- Edge Reinforcement & Eyelet Insertion: The edges of the netting are typically reinforced with a stronger selvedge or hem, often incorporating buttonholes or metal eyelets (grommets) at regular intervals. This reinforcement is critical for secure attachment and to prevent tearing under tension, especially when used as safety netting construction.

- Quality Control & Testing: Throughout the production process, and especially as a final step, rigorous quality control checks are performed. This includes:

- Material Testing: Verifying raw material composition and UV additive levels.

- Tensile Strength Testing: According to international standards like ASTM D638 (Standard Test Method for Tensile Properties of Plastics) or ISO 9001 (Quality Management Systems), ensuring the netting meets specified load-bearing capacities.

- Mesh Size Consistency: Confirming the mesh openings are uniform to effectively contain debris.

- UV Resistance Accelerated Weathering: Testing samples under accelerated UV exposure (e.g., using ASTM G154/G155) to predict real-world service life.

- Fire Retardancy Testing: For FR-treated netting, adherence to standards like NFPA 701 (Standard Methods of Fire Tests for Flame Propagation of Textiles and Films) or California Title 19.

- Cutting & Packaging: The finished netting is cut to specified dimensions, folded, and packaged for shipment, often in rolls or bundles.

The stringent adherence to these manufacturing steps and rigorous testing standards ensures that products like the Safety Net from YJ Wire Mesh deliver exceptional performance and a long service life, typically ranging from 3 to 5 years under normal outdoor conditions, dependent on UV exposure and mechanical stress. The high-quality HDPE material, combined with expert knitting and comprehensive UV stabilization, guarantees a product that retains its strength and integrity over time, offering superior protection in various industries beyond just construction, such as temporary enclosures in petrochemical or waste management facilities for containment, or even agricultural applications requiring windbreak or shade netting (though less common for "debris" specifically).

Diverse Application Scenarios and Unmatched Advantages

Debris netting is a versatile safety solution with applications spanning numerous industries and scenarios:

- Construction Sites: The most common application. Scaffold netting is affixed to scaffolding to contain small tools, debris, and to provide a visual barrier. Safety netting construction also includes perimeter netting around buildings to catch larger falling objects or to prevent personnel falls. This significantly reduces the risk of injury to workers below and passersby.

- Demolition Projects: Essential for containing dust and flying debris during demolition, minimizing environmental impact and protecting surrounding areas.

- Bridges & Infrastructure Repair: Used beneath bridges or elevated structures to catch falling tools, materials, or even to provide a safety platform for workers.

- Industrial Facilities: In power plants, chemical refineries (petrochemical), or manufacturing units, security netting can be used to isolate hazardous areas, prevent accidental falls into machinery pits, or contain loose materials. Its corrosion resistance (due to HDPE) is a key advantage in these environments.

- Sports & Recreation: Occasionally adapted for temporary backstops or barriers.

- Agriculture: While not strictly "debris netting," similar materials are used as bird netting, windbreaks, or shade cloths, demonstrating the material's versatility.

Technical Advantages of High-Performance Debris Netting:

Beyond containment, quality debris netting offers significant advantages:

- Superior UV Resistance: Manufactured with advanced UV stabilizers, our netting ensures prolonged outdoor life, resisting degradation and maintaining structural integrity even under intense sunlight. This significantly extends the product's useful life and reduces replacement costs.

- High Tensile Strength & Impact Absorption: Engineered to withstand significant forces, it can effectively absorb the impact of falling objects, preventing them from causing harm or damage below. This is particularly true for heavy duty debris netting.

- Lightweight & Easy Installation: Despite its strength, HDPE netting is remarkably lightweight, making it easy to handle, transport, and install, saving labor costs and time on site.

- Flame Retardant Options: Available with fire retardant treatments (conforming to standards like NFPA 701), crucial for projects in fire-sensitive environments.

- Breathability: The open mesh design allows for air circulation, reducing wind load on scaffolding and maintaining a comfortable environment for workers, unlike solid tarpaulins.

- Corrosion Resistance: Being made of HDPE, it is inherently resistant to most chemicals, moisture, and biological growth, making it ideal for harsh industrial environments, including those in water supply & drainage or certain metallurgical contexts where traditional materials might corrode. This also contributes to lower maintenance costs.

Choosing Your Partner: Manufacturer Comparison

Selecting the right supplier for your debris netting needs is as critical as the product itself. The market offers various manufacturers, but not all are created equal. When evaluating potential partners, consider the following:

- Quality Assurance & Certifications: Does the manufacturer adhere to international standards like ISO 9001:2015 for quality management? Do their products meet specific performance standards (e.g., ASTM, ANSI, NFPA)? This verifies their commitment to consistent quality.

- Material Purity: Insist on 100% virgin HDPE with robust UV stabilization. Recycled materials or inadequate UV additives can significantly compromise the netting's lifespan and safety performance.

- Customization Capabilities: Can they provide specific sizes, colors, mesh densities, or add features like reinforced hems or logos? A manufacturer offering tailored solutions can better meet unique project requirements.

- Experience & Reputation: How long has the company been in business? What do client testimonials and case studies reveal about their reliability and product performance? A long history of successful projects (like YJ Wire Mesh's extensive experience since 1999) demonstrates proven expertise.

- Technical Support & After-Sales Service: Do they offer comprehensive technical advice on selection, installation, and maintenance? Prompt customer support is invaluable.

- Pricing vs. Value: While competitive pricing is important, prioritize value. A slightly higher initial investment in a superior product often translates to lower long-term costs due to extended durability and enhanced safety.

YJ Wire Mesh's Safety Net: Redefining Site Safety

At YJ Wire Mesh, we are committed to providing top-tier safety solutions that exceed industry expectations. Our Safety Net is a prime example of our dedication to quality, innovation, and client satisfaction. As a leading supplier of debris netting, we pride ourselves on a product that embodies:

- Uncompromising Material Purity: Crafted from 100% virgin HDPE, infused with advanced UV inhibitors, ensuring maximum longevity and resistance to environmental elements.

- Engineered for Excellence: Our netting features a precision-knitted structure, providing superior tensile strength and impact resistance, capable of handling the demands of heavy duty debris netting applications. Each roll undergoes rigorous quality checks to meet and surpass international standards like ASTM and ANSI for safety performance.

- Versatile Applications: Ideal for all safety netting construction scenarios, from scaffolding enclosures to perimeter containment and overhead protection. It also serves effectively as security netting in industrial settings.

- Customization at Its Core: We understand that every project is unique. YJ Wire Mesh offers comprehensive customization options, including specific sizes, custom colors, different mesh densities, and the integration of client branding, ensuring a perfect fit for your specific requirements.

Tailored Safety: Custom Debris Netting Solutions

Standard debris netting meets many needs, but complex projects often require bespoke solutions. YJ Wire Mesh excels in providing custom debris netting tailored to your exact specifications. This includes:

- Specific Dimensions: Netting cut and fabricated to precise lengths and widths for unusual structures or large-scale enclosures, minimizing waste and maximizing coverage.

- Unique Mesh Densities: Adjusting the mesh opening size to contain ultra-fine dust or larger debris, optimizing for specific project risks.

- Color Matching & Branding: Producing netting in specific corporate colors or integrating company logos for enhanced site aesthetics and brand visibility.

- Special Treatments: Applying additional flame retardant treatments to meet rigorous fire safety codes or incorporating anti-static properties for sensitive environments.

- Reinforcement Customization: Varying the type and placement of reinforced edges, grommets, or rope borders for specific attachment methods and load requirements.

Our engineering team works closely with clients from conceptualization to delivery, ensuring that the customized debris netting solution not only meets but exceeds performance expectations, providing unparalleled safety netting construction.

Application Cases and Client Success Stories

YJ Wire Mesh has a proven track record of supplying high-quality debris netting for a diverse range of demanding projects worldwide. Our experience extends to:

- High-Rise Building Construction (e.g., Downtown Commercial Tower): Provided hundreds of thousands of square meters of scaffold netting and perimeter safety netting construction, effectively containing construction debris and enhancing site security. The project saw a significant reduction in reported falling object incidents, improving overall site safety metrics.

- Bridge Renovation Project (e.g., Major Metropolitan Bridge): Supplied custom-sized heavy duty debris netting installed underneath the bridge structure to catch concrete fragments and tools during concrete repair, protecting waterways and minimizing environmental impact. Our netting’s UV resistance ensured durability throughout the multi-year project duration.

- Industrial Facility Maintenance (e.g., Petrochemical Plant Overhaul): Deployed specialized flame-retardant security netting for temporary enclosures during equipment dismantling and reassembly. The netting provided critical containment for small parts and prevented unauthorized access to restricted areas, all while adhering to stringent industrial safety protocols.

These examples underscore our capability to deliver reliable, high-performance debris netting solutions that contribute directly to safer and more efficient operations for our clients.

Ensuring Trust and Reliability: YJ Wire Mesh's Commitment to

At YJ Wire Mesh, our business philosophy is anchored in the principles of Expertise, Experience, Authoritativeness, and Trustworthiness (), ensuring that every client receives not just a product, but a complete safety solution. Our commitment is reflected in every aspect of our operations, from product design to customer support.

- Expertise: With over two decades in the wire mesh and netting industry since 1999, our team possesses unparalleled technical knowledge in polymer science, textile engineering, and safety applications. We stay abreast of the latest international safety standards (e.g., ANSI A10.11 for safety nets, ASTM E2307 for fire resistance) and material advancements, translating this expertise into superior debris netting products.

- Experience: Our extensive portfolio of successful projects, ranging from critical infrastructure developments to large-scale commercial constructions across diverse geographical regions, speaks volumes about our practical experience. We understand the real-world challenges of site safety and offer solutions proven to perform under demanding conditions. Our history includes successful collaborations with numerous leading construction and industrial firms, who rely on our consistent delivery of high-quality products.

- Authoritativeness: YJ Wire Mesh operates under stringent ISO 9001:2015 certified quality management systems, underscoring our commitment to consistent product quality and operational excellence. Our products are regularly tested by independent third-party laboratories to verify adherence to published specifications and relevant industry standards. We are not just a supplier; we are a reputable authority in the field of safety netting construction.

- Trustworthiness: We build trust through transparency, reliability, and unwavering support.

- Delivery Cycle: We maintain efficient production schedules and robust logistics to ensure timely delivery, with typical lead times communicated clearly at the time of order confirmation. For standard products, this can be as short as 1-2 weeks; for custom orders, 3-4 weeks.

- Quality Assurance & Warranty: All our Safety Net products come with a comprehensive warranty against manufacturing defects, typically covering material and workmanship for a specified period (e.g., 1-2 years from purchase). Our commitment to 100% virgin HDPE and robust UV stabilization ensures an expected service life of 3-5 years for our outdoor netting under normal conditions, significantly enhancing project reliability.

- Customer Support: Our dedicated customer service and technical support teams are available to assist with product selection, installation guidance, and any post-purchase inquiries, ensuring a seamless experience from inquiry to application.

Frequently Asked Questions About Debris Netting

1. What is the primary material used for YJ Wire Mesh's Debris Netting?

Our Safety Net (debris netting) is primarily manufactured from 100% virgin High-Density Polyethylene (HDPE), augmented with advanced UV stabilizers. This material choice ensures exceptional durability, resistance to environmental degradation, and a long service life.

2. How does Debris Netting differ from Safety Netting Construction?

While often used interchangeably, "debris netting" specifically refers to netting designed to catch small falling objects and provide a barrier, typically with a smaller mesh. "Safety netting construction" is a broader term encompassing all types of netting used for fall protection, including personnel fall nets which have larger, stronger meshes, in addition to debris nets. Our product often serves both purposes when used as scaffold netting.

3. What are the typical mesh sizes available for heavy duty debris netting?

For heavy duty debris netting, mesh sizes typically range from 2mm x 2mm for very fine containment to 5mm x 5mm, providing a balance between effective debris capture and adequate airflow. The specific choice depends on the size of the debris being contained.

4. Can YJ Wire Mesh provide flame-retardant debris netting?

Yes, we offer debris netting treated with flame retardants, conforming to international standards such as NFPA 701 (Standard Methods of Fire Tests for Flame Propagation of Textiles and Films). This is crucial for projects in high-risk or regulated environments.

5. What is the expected service life of your debris netting?

Thanks to our use of 100% virgin HDPE and advanced UV stabilization, our debris netting has an expected outdoor service life of 3 to 5 years under normal weather conditions. Proper storage and maintenance can further extend its usability.

6. How is debris netting installed on scaffolding?

Scaffold netting is typically installed using cable ties, bungee cords, or specialty clips that attach to the existing scaffolding structure. Our netting features reinforced edges with integrated buttonholes or grommets for easy and secure attachment, ensuring proper tension and coverage. Always follow local safety guidelines and manufacturer's instructions for installation.

7. Is your debris netting recyclable?

Yes, as our debris netting is made from HDPE, it is generally recyclable. We encourage clients to responsibly dispose of or recycle materials at the end of their service life to support environmental sustainability. Specific recycling capabilities may vary by region.

Elevate your site safety and operational efficiency with YJ Wire Mesh's superior debris netting solutions.

Contact us today for a consultation or to request a quote for your project!

Learn More About Our Safety NetReferences and Further Reading:

- Occupational Safety and Health Administration (OSHA). "Safety and Health Regulations for Construction." https://www.osha.gov/laws-regs/regulations/standardnumber/1926

- ASTM International. "Standards for Plastics." https://www.astm.org/products/standards-and-publications/standards/D638.html

- National Fire Protection Association (NFPA). "NFPA 701: Standard Methods of Fire Tests for Flame Propagation of Textiles and Films." https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?productid=701SY19

- PwC. "Global Construction 2030." (Accessed via industry reports, specific direct link often behind paywalls, but widely cited in construction market analyses). For a general overview: https://www.pwc.com/gx/en/industries/capital-projects-infrastructure/construction.html

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025