-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

desiccant bags for shipping containers

The Importance of Desiccant Bags for Shipping Containers

In today's globalized economy, the shipping industry plays a vital role in the transportation of goods across long distances. However, one of the significant challenges faced during shipping is moisture control inside containers. Excessive humidity can lead to a myriad of problems, such as mold growth, product spoilage, and corrosion of metal goods. To combat these issues, many businesses are turning to desiccant bags as an effective solution for maintaining a stable, dry environment within shipping containers.

Desiccant bags are small pouches filled with hygroscopic substances, which are materials that absorb moisture from the air. Common desiccants include silica gel, clay, activated charcoal, and molecular sieves. These materials are selected for their high adsorption capacities and can significantly reduce the humidity levels inside shipping containers, ensuring that the cargo arrives in optimal condition.

One of the primary benefits of using desiccant bags is their effectiveness in preserving product integrity. For example, electronic components, pharmaceuticals, and food items are particularly susceptible to moisture damage. Rust can form on electronic devices, while food products can become stale or develop mold when exposed to damp conditions. By placing desiccant bags within the container, companies can mitigate these risks and ensure that their products remain safe and usable upon delivery.

In addition to protecting the cargo itself, desiccant bags also assist in prolonging the shelf life of products. For instance, items like dried fruits, spices, and herbs can lose their flavor and nutritional value if exposed to moisture. By using desiccant bags during shipping, businesses can ensure that their products retain their quality and appeal to consumers, which can be a critical factor in maintaining customer satisfaction and loyalty.

desiccant bags for shipping containers

Moreover, the use of desiccant bags can help prevent logistical issues and reduce costs associated with damaged goods. When products are returned due to spoilage or quality concerns, it can lead to unexpected financial losses and strained relationships with retailers and customers. By proactively employing moisture control measures, companies can minimize the risk of damage, streamline their operations, and maintain a reliable supply chain.

From an environmental perspective, desiccant bags can also be beneficial. Many modern desiccant products are designed to be non-toxic and environmentally friendly. Additionally, the use of desiccants can reduce the need for extensive packaging or refrigeration that is often required to protect moisture-sensitive goods. This can lead to a smaller carbon footprint during transportation and align with the sustainability goals of many companies today.

When implementing desiccant bags in shipping containers, it's essential to consider the size and type of desiccant used based on the cargo and container specifications. Generally, the quantity of desiccant bags required will depend on the container's dimensions, the expected humidity levels during transit, and the sensitivity of the goods being shipped. Properly calculating these factors will ensure optimal moisture control.

Furthermore, businesses should also pay attention to the placement of desiccant bags within the shipping container. Distributing the bags evenly can maximize their effectiveness, allowing for more thorough moisture absorption throughout the container space. Monitoring the performance of desiccant bags can also be useful; some products come with indicators that change color when the moisture saturation point is reached, allowing for timely replacement.

In conclusion, desiccant bags are an essential tool for maintaining a dry environment within shipping containers, safeguarding products from moisture-related damage, and ensuring their quality. As shipping continues to evolve, incorporating effective moisture control strategies will remain crucial for businesses striving for excellence in logistics, customer satisfaction, and sustainability. By understanding the significance of desiccants and employing them effectively, companies can navigate the challenges of moisture control and protect their valuable cargo during transit.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

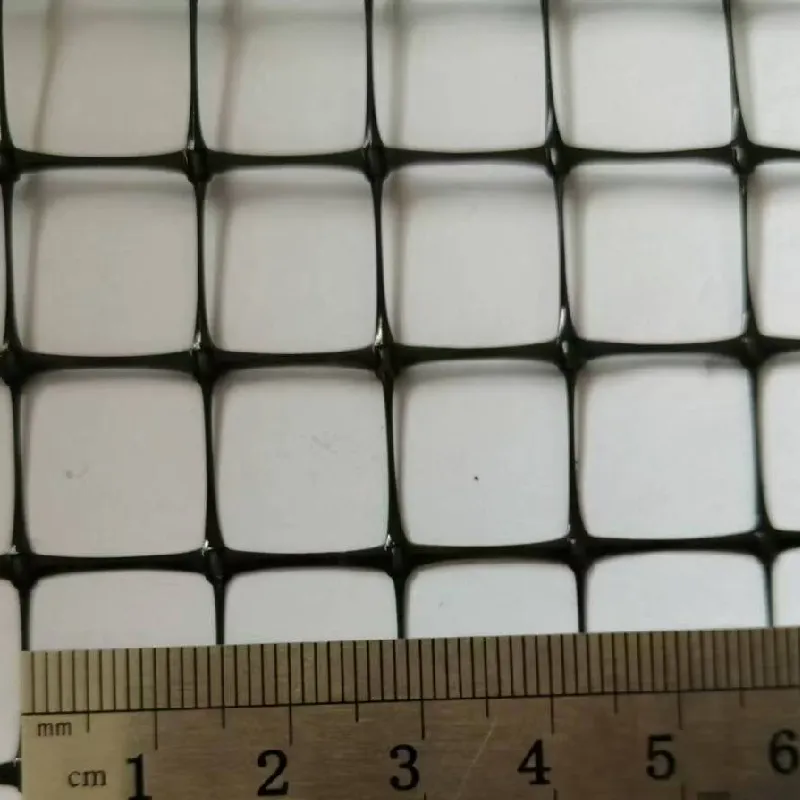

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025