-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable and Versatile Stainless Steel Square Mesh for Various Applications and Industries

The Versatility and Applications of Stainless Steel Square Mesh

Stainless steel square mesh has emerged as a crucial element in various industrial and commercial applications. Its unique properties, including durability, resistance to corrosion, and aesthetic appeal, make it an ideal choice for many sectors ranging from construction to manufacturing and even artistic endeavors. In this article, we will explore the characteristics, manufacturing process, and diverse uses of stainless steel square mesh.

Characteristics of Stainless Steel Square Mesh

Stainless steel square mesh is composed primarily of stainless steel, which is an alloy that typically contains iron, carbon, and chromium. The inclusion of chromium significantly enhances the material’s resistance to rust and oxidation, making it suitable for environments that may be prone to moisture or corrosive elements. This unique feature provides not only longevity but also a lower maintenance requirement, which is a critical advantage in industrial settings.

Moreover, the square mesh design provides uniform openings that can be tailored to specific sizes depending on the application. This customization allows for excellent airflow and drainage while still providing the necessary strength and support. The mesh's rigidity and tensile strength make it capable of withstanding substantial loads, making it an ideal choice for construction and architecture where structural integrity is paramount.

Manufacturing Process

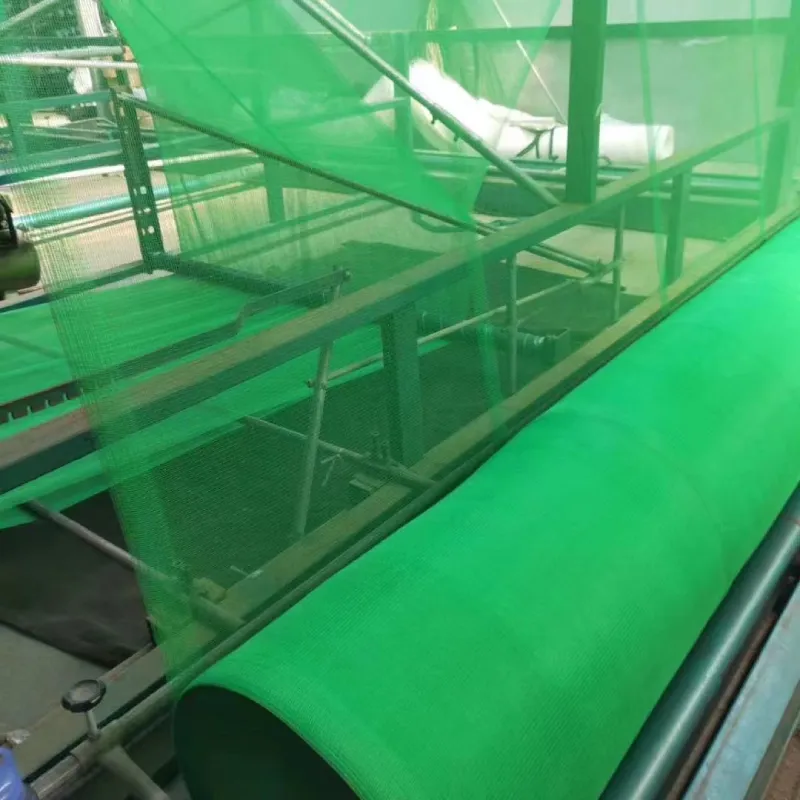

The manufacturing of stainless steel square mesh typically involves weaving stainless steel wires together to form a grid. The wires can vary in gauge and finish based on the intended use of the mesh. The weaving process can be mechanical or manual, with advancements in technology enabling more precise and efficient production techniques.

stainless steel square mesh

Once woven, the mesh can undergo additional treatments, such as polishing or coating, to enhance its appearance and further improve its corrosion resistance. This adaptability in manufacturing ensures that stainless steel square mesh can meet varying standards and specifications required by different industries.

Applications of Stainless Steel Square Mesh

The versatility of stainless steel square mesh translates into a broad range of applications. In the construction industry, it is often used as reinforcement in concrete, providing strength and stability to various structures. Its applications extend to facades and railings, where aesthetic designs can harmonize with its functional benefits.

In the food and beverage industry, stainless steel square mesh is favored for its sanitary properties. It is commonly employed in processing plants, packaging, and transportation equipment due to its resistance to bacteria and ease of cleaning. This makes it a preferred material for items like strainers, filters, and conveyor systems.

Apart from industrial applications, stainless steel square mesh is also popular in landscaping and horticulture. Gardeners and landscapers use this mesh as trellises and supports for plants, as well as protective fencing to keep pests away from cultivated areas. Additionally, its use in art installations and decorative elements allows designers to incorporate both beauty and functionality into their work.

Conclusion

Stainless steel square mesh is an invaluable material that combines strength, versatility, and aesthetic appeal. Its unique properties make it an appropriate choice for a myriad of applications across various industries, from construction and food processing to art and landscaping. As industries continue to innovate and evolve, the demand for stainless steel square mesh is likely to become even more pronounced, driving advancements in manufacturing and design. Whether reinforcing a structure or creating art, stainless steel square mesh represents a perfect fusion of functionality and style, standing as a testament to modern engineering and design.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025