-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable Insect Proof Mesh: Your Ultimate Bug Barrier

Strategic Imperatives: Leveraging Advanced Insect Proof Mesh for Sustainable Growth

In an era increasingly focused on sustainability, efficiency, and public health, the role of protective barriers in various industrial, agricultural, and residential sectors has never been more critical. As a cornerstone technology in integrated pest management (IPM) strategies, insect proof mesh offers a sophisticated, non-chemical solution to pest control, delivering multifaceted benefits that extend beyond mere containment. This comprehensive article delves into the intricate world of advanced insect proof netting, exploring its pivotal role in shaping modern agricultural practices, safeguarding industrial processes, and enhancing public health initiatives. We will dissect the technical parameters that define superior mesh products, illuminate the meticulous manufacturing processes that ensure their efficacy, and analyze diverse application scenarios where these nets prove indispensable. Furthermore, we will provide a rigorous examination of the technical advantages, including energy efficiency and corrosion resistance, alongside a comparative analysis of leading manufacturers. Our discussion will also encompass bespoke customization options and showcase compelling application cases supported by empirical data, culminating in an exploration of quality assurance protocols and customer support mechanisms that underscore trustworthiness and reliability. This exposition is tailored for B2B decision-makers, technical specialists, and procurement professionals seeking to optimize operational resilience, mitigate risks, and embrace environmentally responsible solutions.

Navigating Industry Trends and Market Dynamics in Pest Exclusion Technologies

The global market for protective netting, particularly in the agricultural sector, is experiencing robust growth, primarily driven by an escalating demand for safe and sustainable food production practices. With increasing regulatory pressures on synthetic pesticides and a heightened consumer awareness regarding food safety and environmental impact, physical barrier solutions like insect proof mesh are rapidly gaining traction. According to recent market analyses, the global agricultural net market, which includes various types of protective nets such as insect net and shade nets, is projected to reach approximately USD 1.8 billion by 2028, growing at a Compound Annual Growth Rate (CAGR) of around 6.5% from 2023. This upward trajectory is influenced by several macro-environmental factors: the imperative for climate change adaptation, which necessitates resilient agricultural infrastructure; the proliferation of resistant pest strains, rendering conventional chemical treatments less effective; and the pervasive shift towards organic and integrated pest management (IPM) systems. Innovations in polymer science and weaving technologies are further propelling this market expansion, leading to the development of more durable, UV-resistant, and finely tuned meshes. The integration of bug netting solutions into smart farming ecosystems, where environmental controls and pest monitoring are automated, represents another significant trend, promising enhanced efficiency and precision. Beyond agriculture, public health initiatives, especially in regions prone to vector-borne diseases, are driving demand for effective mosquito and insect barriers, exemplified by the increased adoption of head nets for bugs and outdoor bug net solutions in recreational and residential settings. This holistic market evolution underscores the indispensable role of advanced insect proof barriers as a strategic investment for businesses aiming to secure their assets, ensure product integrity, and contribute positively to ecological stewardship.

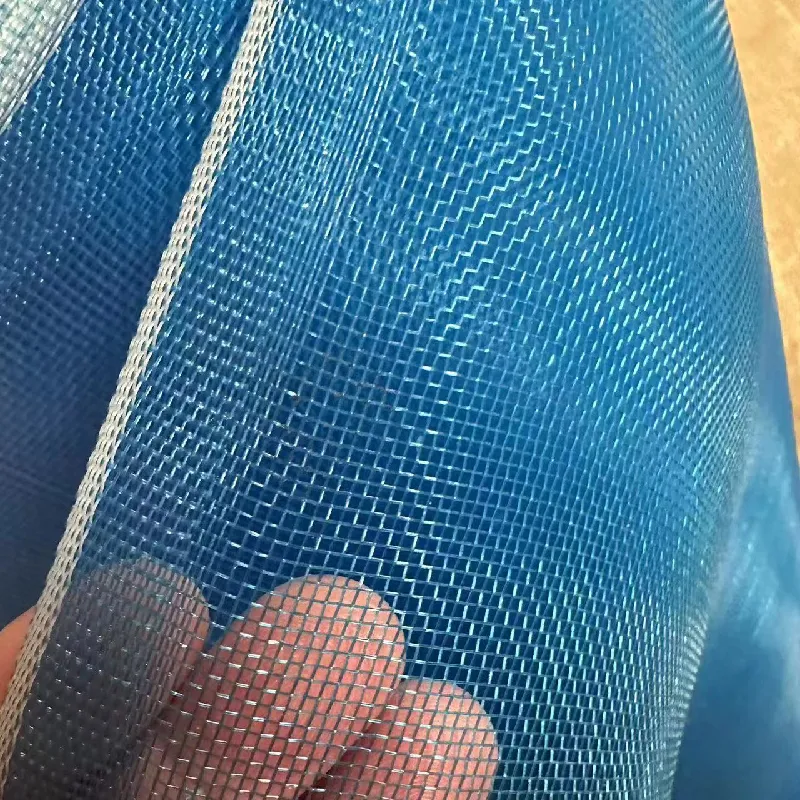

Unpacking Technical Specifications: The Science Behind High-Performance Insect Proof Netting

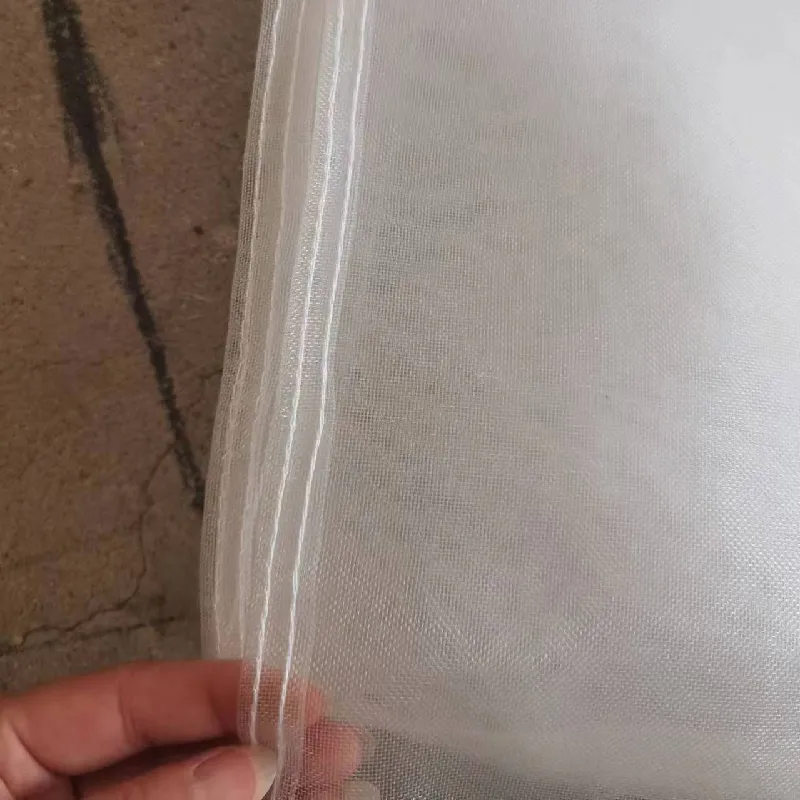

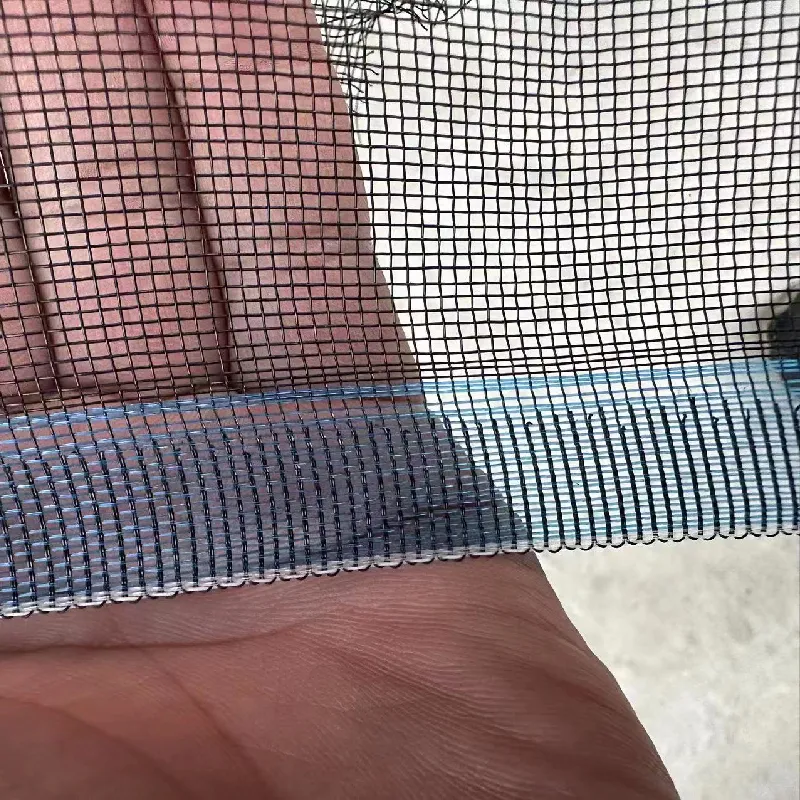

The efficacy and longevity of any insect proof mesh hinge upon its precise technical specifications and the judicious selection of raw materials. Understanding these parameters is crucial for B2B procurement professionals to ensure the chosen product aligns perfectly with operational requirements and environmental challenges. Key material choices often include High-Density Polyethylene (HDPE), Nylon, Fiberglass, and even Stainless Steel for specialized industrial applications. HDPE, known for its excellent strength-to-density ratio, UV resistance, and chemical inertness, is a dominant choice for agricultural insect net due to its durability and cost-effectiveness. Nylon offers superior tensile strength and abrasion resistance, making it suitable for applications requiring higher mechanical resilience. Fiberglass, commonly used in residential window screens, provides good airflow and visibility. Stainless steel, while more expensive, offers unparalleled corrosion resistance, high temperature tolerance, and extreme durability for demanding industrial filtration or architectural uses, especially in environments exposed to aggressive chemicals or high temperatures, such as those found in petrochemical or metallurgical industries, where its inherent strength and non-reactivity are paramount for preventing foreign object ingress and ensuring operational integrity.

The primary technical specifications defining an insect proof mesh include:

- Mesh Count (or Hole Size): This is arguably the most critical parameter, determining the size of insects that can be excluded. It's typically expressed as the number of threads per inch (TPI) or holes per square inch. For instance, a 50-mesh screen (50 threads per inch) can block very small insects like whiteflies and aphids, while a 20-mesh might be sufficient for larger pests like fruit flies. The optimal mesh count depends entirely on the target pest spectrum. Different mesh counts are designed to block specific insect sizes, ranging from broad protection against beetles to microscopic barriers against thrips or even fungal spores carried by insects.

- Wire/Thread Diameter: The thickness of the individual filaments or wires. A thicker diameter generally implies greater strength and durability but can reduce airflow and light transmission. Balancing this with mesh count is vital for optimal performance.

- Weave Pattern: Common patterns include plain weave (simple over-under) and leno weave (warp threads twisted around weft threads), the latter offering enhanced stability and tear resistance, particularly important for bug netting under mechanical stress or in high-wind environments.

- UV Stabilization: Essential for outdoor applications, this refers to the net's ability to resist degradation from ultraviolet radiation. High-quality insect proof mesh integrates UV stabilizers during manufacturing, significantly extending its service life (often 5-10 years or more, depending on climate). This property directly impacts the return on investment.

- Tensile Strength: Measured in pounds per square inch (PSI) or Newtons (N), this indicates the force required to break the material when pulled. High tensile strength ensures the mesh can withstand environmental stresses, such as wind, hail, or even the weight of accumulated debris.

- Burst Strength: Reflects the mesh's resistance to a sudden, concentrated force (e.g., impact from a falling object or strong pressure).

- Airflow Permeability: A measure of how easily air passes through the mesh. While finer meshes offer superior pest exclusion, they can impede airflow, potentially leading to increased temperatures and humidity within enclosed spaces like greenhouses. An optimal balance is crucial.

- Light Transmission: The percentage of sunlight that passes through the mesh. Different crops and applications require varying light levels. Some meshes are designed to diffuse light, reducing hot spots and improving crop uniformity.

- Weight (g/m²): Influences ease of installation, structural requirements, and overall cost.

- Dimensions: Available in various widths and lengths, often customizable to project specifications, minimizing waste and simplifying installation for large-scale outdoor bug net projects.

- Temperature Range: The operational temperature spectrum the mesh can withstand without degradation, crucial for diverse climates and industrial applications.

- Chemical Resistance: The ability to withstand exposure to agricultural chemicals, cleaning agents, or industrial solvents without compromising structural integrity.

Adherence to international standards such as ISO (International Organization for Standardization) for quality management (e.g., ISO 9001) and ANSI (American National Standards Institute) for product performance specifications is paramount. For instance, textile testing standards like ASTM D3775 (fabric count), ASTM D5034 (breaking strength), and accelerated weathering tests (e.g., ASTM G154 for UV exposure) provide a quantitative basis for product quality and projected service life. When considering head nets for bugs or other personal protection gear, additional standards for breathability and comfort might apply. Below is a detailed product specification table for a typical high-performance Insect Proof Net, showcasing the critical parameters that ensure superior performance and longevity.

| Parameter | Typical Specification for Insect Proof Net | Significance & Industry Standard |

|---|---|---|

| Material | 100% Virgin HDPE (High-Density Polyethylene) with UV Stabilizers | Ensures durability, chemical resistance, and extended outdoor lifespan. Conforms to relevant polymer safety standards. |

| Mesh Count | 50 Mesh (50 threads per inch, equivalent to ~0.3mm hole size) | Optimal for blocking whiteflies, aphids, thrips, and leafminers. Critical for specific pest exclusion as per agricultural best practices. |

| Wire/Thread Diameter | 0.23 mm - 0.28 mm | Balances strength with minimal light/airflow obstruction. Tested for uniformity. |

| Weight | 100-140 g/m² (grams per square meter) | Indicates material density and contributes to structural integrity. Measured per ISO 3801. |

| UV Resistance | Minimum 5 years UV stabilization (equivalent to 1000 Kly or 5000+ hours QUV accelerated weathering) | Crucial for outdoor durability; tested via ASTM G154 or ISO 4892-3 for accelerated aging. Ensures long service life in harsh sunlight. |

| Tensile Strength (Warp/Weft) | ≥ 250 N/5cm (Warp), ≥ 200 N/5cm (Weft) | Measures resistance to breaking under tension. Verified using ISO 13934-1 (Strip Method) for textile fabrics. Critical for wind load resistance. |

| Tear Resistance | ≥ 60 N (Trapezoid Method) | Indicates resistance to propagation of tears once initiated. Measured per ASTM D5733 (Trapezoid Tear Test). |

| Light Transmission | 85-90% | Ensures adequate light for photosynthesis while providing protection. Measured by spectrophotometer. |

| Color Options | White (Standard), Black, Green (Customizable) | Aesthetics and specific light spectrum management for plant growth. Colorfastness tested. |

| Width & Length | Standard widths from 1m to 6m; lengths up to 1000m (Customizable) | Versatility for various applications, from small greenhouses to large agricultural fields. |

| Operational Temperature Range | -30°C to +70°C | Ensures material integrity across diverse climatic conditions. |

The detailed understanding of these specifications allows for informed decisions, ensuring that the deployed insect proof mesh not only meets immediate pest control needs but also offers long-term durability, cost efficiency, and performance under specific environmental and operational conditions. This granular approach to product selection is a hallmark of strategic procurement in the B2B landscape.

The Advanced Manufacturing Process of Insect Proof Netting: Precision, Purity, and Performance

The production of high-performance insect proof mesh is a sophisticated multi-stage process that combines advanced polymer science with precision engineering. It goes far beyond simple weaving, encompassing rigorous material selection, state-of-the-art manufacturing techniques, and stringent quality control protocols to ensure a product that delivers consistent and reliable pest exclusion. The typical manufacturing flow for polyethylene-based insect net involves several critical steps, each contributing to the final product's durability, filtration efficacy, and environmental resilience.

1. Raw Material Sourcing and Preparation:

The foundation of a superior insect proof mesh begins with the selection of high-grade raw materials. For most agricultural and horticultural applications, 100% virgin High-Density Polyethylene (HDPE) granules are preferred due to their inherent strength, chemical resistance, and non-toxic properties. Crucially, UV stabilizers and, where required, anti-oxidants and color pigments are meticulously blended with the virgin HDPE resin. This compounding process is critical for endowing the mesh with its long-term resistance to photodegradation (breakdown by sunlight) and maintaining its physical integrity over extended periods, typically ensuring a service life of 5 to 10 years even in intense solar radiation environments. The precise ratio and type of UV stabilizers are proprietary and are often the secret behind a manufacturer's superior product longevity. For specialized applications requiring different material properties, such as metallic bug netting (e.g., stainless steel), the process would start with high-purity metal alloys, subjected to controlled annealing and drawing processes to achieve the desired wire characteristics.

2. Extrusion and Monofilament Drawing:

The prepared HDPE compound is fed into an extruder, where it is melted under precise temperature and pressure controls. The molten polymer is then forced through a die to form continuous, uniform monofilaments (single strands) of specific diameters. This extrusion process requires highly accurate dies and consistent temperature profiles to ensure thread uniformity, which is paramount for maintaining consistent mesh openings and preventing weak points. For metallic meshes, this stage involves wire drawing, where metal rods are pulled through a series of progressively smaller dies to reduce their diameter to the required gauge, strengthening the wire in the process. This meticulous process, similar to CNC machining in its precision requirements, ensures that each filament is perfectly round and possesses the optimal tensile strength necessary for durable weaving.

3. Weaving/Knitting Process:

The extruded monofilaments are then spooled and loaded onto advanced weaving or knitting looms. For agricultural insect proof mesh, leno weave (also known as gauze weave) is often employed. In this specialized weaving technique, two warp threads are twisted around the weft thread, creating a strong, stable structure that resists unraveling and shifting of the mesh, even when cut. This open, yet robust, construction is vital for maintaining consistent mesh openings, which are crucial for effective pest exclusion while allowing optimal airflow and light transmission. Precision looms with electronic control systems are utilized to ensure uniform tension and consistent mesh count across the entire width and length of the fabric. This level of precision is analogous to the exacting standards found in advanced manufacturing processes like CNC machining, where dimensional accuracy is non-negotiable. For bug netting designed for specific industrial or architectural applications, other weaving patterns like plain weave or twill weave might be used based on desired strength, flexibility, or aesthetic properties.

4. Finishing and Heat Setting:

After weaving, the raw mesh fabric undergoes a critical heat-setting process. This involves passing the mesh through controlled heating chambers, which stabilizes the weave structure and eliminates residual stresses from the weaving process. Heat setting enhances dimensional stability, prevents shrinkage, and improves the overall resilience of the insect proof mesh against environmental fluctuations. Depending on the application, additional finishing treatments may be applied, such as anti-static coatings to repel dust, or specialized treatments to enhance flame retardancy or antimicrobial properties, particularly relevant for meshes used in food processing or healthcare environments. This meticulous finishing contributes significantly to the product's longevity and performance.

5. Rigorous Quality Control and Testing:

Quality assurance is integrated at every stage of the manufacturing process, from raw material inspection to final product verification. This comprehensive approach ensures that every roll of insect proof mesh meets stringent international standards and performance specifications. Key quality control points include:

- Material Purity Testing: Verifying the composition and quality of HDPE granules and UV stabilizers using techniques like Fourier-transform infrared spectroscopy (FTIR).

- Monofilament Gauge and Uniformity: Regular checks on the diameter and consistency of extruded filaments using laser micrometers.

- Mesh Count Verification: Precisely measuring the number of threads per inch or centimeter using calibrated magnifying tools, ensuring the exact hole size for pest exclusion.

- Tensile and Tear Strength Testing: Samples from each batch are subjected to tensile testing (e.g., ISO 13934-1, ASTM D5034) and tear resistance tests (e.g., ASTM D5733) to confirm mechanical robustness.

- UV Resistance Testing: Accelerated weathering tests (e.g., ISO 4892-3, ASTM G154) expose mesh samples to intense UV radiation and simulated weather cycles to predict long-term outdoor performance and ensure the stated service life.

- Light Transmission and Airflow Permeability: Specialized equipment measures how much light passes through and the rate of airflow, ensuring optimal environmental conditions within protected areas.

- Dimensional Stability and Shrinkage Tests: Confirming the mesh will retain its dimensions under varying temperature and humidity.

- Visual Inspection: Thorough checks for defects such as uneven weaving, snags, or discoloration.

Technical Advantages and Performance Excellence of Advanced Insect Proof Mesh

The deployment of high-grade insect proof mesh offers a multitude of technical advantages that directly translate into operational efficiencies, cost savings, and enhanced sustainability across various sectors. These benefits underscore why leading industries are increasingly moving away from chemical-intensive solutions towards sophisticated physical barriers.

1. Superior Pest Exclusion and Crop Protection:

The primary advantage of insect proof mesh is its unparalleled ability to create an impenetrable physical barrier against a wide spectrum of insect pests, from microscopic thrips and whiteflies (requiring 50-mesh or finer) to larger aphids, leafminers, and even birds and bats. By preventing pest ingress, the mesh eliminates the need for frequent and often harmful chemical pesticide applications. This not only safeguards crop health and yield but also protects beneficial insects and pollinators, which are vital for ecological balance. In controlled environments like greenhouses, an optimized insect net can virtually eliminate pest infestations, leading to healthier plants, higher-quality produce, and significantly reduced crop losses. This precision pest management contrasts sharply with traditional methods, which often involve reactive and broad-spectrum chemical interventions.

2. Eco-Friendly and Sustainable Solution:

By drastically reducing or entirely eliminating the reliance on chemical pesticides, insect proof mesh contributes significantly to environmental sustainability. This translates to less soil and water contamination, preservation of biodiversity, and safer working conditions for agricultural laborers. It aligns perfectly with organic farming standards and integrated pest management (IPM) strategies, which prioritize ecological approaches. The long service life of high-quality HDPE meshes (often exceeding 5-7 years) further enhances their environmental credentials by minimizing waste and resource consumption associated with frequent replacement. This long-term durability makes it an economical choice for large-scale agricultural operations or expansive outdoor bug net installations.

3. Optimized Microclimate and Resource Efficiency:

Beyond pest exclusion, advanced insect proof mesh plays a crucial role in microclimate management. While providing effective barriers, engineered meshes maintain optimal airflow, preventing excessive heat buildup and humidity, which can otherwise foster fungal diseases. Simultaneously, they offer controlled light transmission and diffusion, reducing solar radiation intensity, preventing scorching, and ensuring uniform light distribution for enhanced photosynthesis. This optimized microclimate promotes healthier plant growth, leading to improved yields and quality. In contexts like greenhouses, this also translates to reduced energy consumption for cooling and ventilation, leading to significant operational cost savings. For bug netting used in public spaces, this means comfortable airflow while maintaining protective qualities.

4. Exceptional Durability and Longevity:

High-quality insect proof mesh, particularly those made from virgin HDPE with integrated UV stabilizers, are designed for extreme durability. They exhibit remarkable resistance to UV degradation, tearing, abrasion, and a wide range of chemicals. This resilience ensures a long service life, typically 5-10 years or even longer depending on environmental conditions and maintenance. Such longevity significantly reduces the total cost of ownership (TCO) by minimizing replacement frequency and associated labor costs. The robust construction ensures the mesh can withstand harsh weather conditions, including strong winds, hail, and heavy rainfall, maintaining its structural integrity and protective function. This feature is particularly important for large-scale agricultural installations or for outdoor bug net applications that are permanently installed.

5. Cost-Effectiveness and Return on Investment (ROI):

While the initial investment in high-quality insect proof mesh might seem higher than chemical treatments, the long-term economic benefits are substantial. Significant savings are realized through:

- Reduced Pesticide Costs: Elimination or drastic reduction in chemical spray purchases.

- Lower Labor Costs: Less time spent on spraying and monitoring for pests.

- Increased Yield and Quality: Healthier crops lead to higher market value and fewer rejections due to pest damage.

- Energy Savings: Optimized microclimate in greenhouses reduces heating/cooling demands.

- Reduced Health Risks: Fewer worker health issues associated with pesticide exposure, leading to lower healthcare costs and higher productivity.

Diverse Application Scenarios: Where Insect Proof Mesh Delivers Value

The versatility and efficacy of insect proof mesh extend across a remarkably diverse range of applications, each benefiting from its inherent properties of physical barrier protection, environmental control, and durability. From safeguarding critical agricultural yields to ensuring public health and maintaining hygienic industrial environments, this technology is a foundational element in modern operational strategies.

1. Agriculture and Horticulture: The Primary Domain

This sector represents the largest application area for insect proof mesh. In greenhouses, shade houses, and nurseries, the mesh forms the primary line of defense against a multitude of airborne pests, including whiteflies (Bemisia tabaci), aphids (Myzus persicae), thrips (Frankliniella occidentalis), and leafminers (Liriomyza spp.), which can devastate crops and transmit plant viruses. Specific mesh counts are chosen based on the smallest target pest; for instance, 50-mesh is often specified for thrips and whiteflies, while coarser meshes might be used for larger insects. The mesh is integrated into greenhouse ventilation systems, sidewalls, and roof openings, allowing for essential air circulation while preventing pest entry. In open field cultivation, insect net tunnels or row covers are employed to protect high-value crops like vegetables, fruits (e.g., berries), and organic produce from insect damage, often combined with drip irrigation systems. This application directly reduces the need for frequent pesticide spraying, enabling growers to meet organic certification requirements and achieve higher market prices for their unblemished produce. The deployment of bug netting in these settings has been proven to significantly increase marketable yield and enhance overall crop quality by reducing physical damage and disease transmission. For example, studies by the FAO have consistently shown yield increases of 20-40% in various crops when protected by suitable netting.

2. Residential and Commercial Buildings: Enhancing Comfort and Hygiene

Beyond agriculture, insect proof mesh is widely utilized in residential and commercial architecture. Standard window and door screens, patio enclosures, and screened-in porches rely on durable bug netting (often fiberglass or aluminum/stainless steel mesh) to prevent mosquitoes, flies, and other bothersome insects from entering living and working spaces. In commercial establishments, particularly those in the hospitality, food service, and retail sectors, effective insect barriers are paramount for maintaining hygiene standards and complying with health regulations. Restaurants, food processing facilities, and warehouses strategically install fine insect proof mesh on windows, doors, and ventilation points to prevent contamination and pest infestations, thereby safeguarding product integrity and public health. The mesh must be durable, easy to clean, and often fire-retardant in these contexts. For outdoor recreational areas, the use of outdoor bug net structures or temporary enclosures can significantly enhance user comfort by creating insect-free zones.

3. Public Health and Disease Vector Control: A Critical Barrier

In regions afflicted by mosquito-borne diseases such as malaria, dengue, Zika, and West Nile virus, insect proof mesh plays a vital role in public health interventions. Large-scale deployment of mosquito nets (a form of insect net), especially permethrin-treated bed nets, has been instrumental in reducing disease transmission. However, non-treated insect proof mesh on windows and doors of homes, clinics, and schools offers a sustainable, long-term physical barrier against disease vectors. For outdoor workers or individuals in high-risk areas, specialized head nets for bugs or full-body outdoor bug net suits provide essential personal protection. This application underscores the mesh's role not just in comfort but in preventing serious health crises by breaking the chain of transmission.

4. Industrial and Specialized Applications: Beyond Pest Control

The robust nature and precise filtration capabilities of certain insect proof mesh types make them suitable for a variety of industrial applications. This includes:

- Filtration Systems: Fine meshes can be used in air filtration systems to prevent the ingress of larger insects or debris into sensitive machinery or cleanroom environments in industries like electronics manufacturing or pharmaceuticals.

- Water Treatment: Coarser meshes act as pre-filters in water intake systems to block leaves, large debris, and aquatic insects, protecting pumps and finer filtration stages in industries like petrochemical, metallurgy, and municipal water supply/drainage. The corrosion-resistant properties of stainless steel mesh are particularly beneficial here.

- Protective Barriers: In industrial settings, durable netting can serve as safety barriers to prevent birds or larger animals from entering production areas, storage facilities, or waste management sites.

- Construction: Temporary bug netting can be used on construction sites to prevent insects from entering fresh concrete or paint, or to protect workers from stinging insects in infested areas.

The broad applicability of insect proof mesh across these diverse sectors highlights its fundamental utility as a reliable, non-chemical, and economically viable solution for physical barrier protection, environmental control, and operational integrity. Its capacity to adapt to various specific needs, from delicate crop protection to robust industrial filtration, solidifies its position as an indispensable component in modern infrastructure and sustainable development.

Customization and Bespoke Solutions: Tailoring Insect Proof Mesh for Unique Demands

While standard insect proof mesh products serve a wide array of applications, many B2B projects, particularly those involving large-scale agricultural installations, complex industrial systems, or specialized architectural designs, demand highly customized solutions. A leading manufacturer distinguishes itself not only by the quality of its standard offerings but also by its capacity to engineer bespoke netting solutions that precisely meet unique project specifications. This customization capability is crucial for optimizing performance, minimizing waste, and achieving seamless integration into existing infrastructure.

Tailoring Mesh Parameters:

- Custom Mesh Count and Hole Size: The most frequent customization involves adapting the mesh count to target specific pest sizes. For instance, an operation battling microscopic thrips might require an ultra-fine 80-mesh, while a different farm targeting larger beetles might opt for a 20-mesh. This precise engineering ensures maximum exclusion efficiency without unnecessarily impeding airflow or light.

- Variable Widths and Lengths: Standard rolls might not always be ideal for vast greenhouses or expansive field coverings. Manufacturers can produce insect proof mesh in extra-wide formats (e.g., 8m, 10m, or even wider) or exceptionally long rolls (e.g., 500m, 1000m) to reduce the number of seams, minimize installation time, and enhance structural integrity, especially crucial for large outdoor bug net structures.

- Thread Diameter Optimization: Balancing strength with light and airflow needs, the diameter of the individual monofilaments can be adjusted. Thicker threads enhance tear resistance and durability for high-stress applications, while thinner threads maximize light penetration and ventilation.

Specialized Treatments and Additives:

- Enhanced UV Stabilization: For projects in regions with extremely high solar radiation (e.g., equatorial climates, high altitudes), the concentration and type of UV stabilizers can be boosted to provide an extended service life beyond the standard 5-7 years, potentially reaching 10-12 years. This extra resilience is vital for insect net installations expected to endure harsh, prolonged sun exposure.

- Fire Retardancy: In certain industrial or commercial building applications where fire safety is paramount (e.g., public buildings, sensitive industrial facilities), flame-retardant additives can be incorporated into the polymer during extrusion, ensuring the bug netting meets relevant fire safety standards (e.g., NFPA 701, EN 13501-1).

- Antimicrobial Properties: For food processing facilities, healthcare environments, or areas with high humidity, antimicrobial agents can be infused into the mesh to inhibit the growth of mold, mildew, and bacteria, contributing to improved hygiene and reduced maintenance.

- Color Customization: While white is standard for light transmission, specific projects might require different colors for aesthetic reasons, camouflage, or even to influence light spectrum. For example, some studies suggest certain colors can deter specific insects or selectively filter light for optimized plant growth.

- Anti-Static Treatment: In dusty environments or industrial settings where static electricity is a concern, anti-static coatings can be applied to prevent dust accumulation on the mesh surface, ensuring sustained airflow and ease of cleaning.

Pre-Fabrication and Integration Services:

Beyond material properties, customization extends to the physical form of the insect proof mesh. Manufacturers can offer:

- Pre-cut Panels: Providing mesh cut to precise dimensions for windows, doors, or specific structural openings, minimizing on-site cutting and waste.

- Reinforced Edges and Grommets: For applications requiring high tension or frequent handling, meshes can be supplied with reinforced selvedges or integrated grommets for easier and more secure installation.

- Custom Seaming/Welding: For very large covers or unique shapes, advanced welding or seaming techniques can join multiple mesh panels to create seamless, oversized insect net solutions, ensuring maximum coverage and structural integrity.

The ability to provide highly customized insect proof mesh solutions is a testament to a manufacturer's engineering prowess and commitment to client success. It involves close consultation with clients to understand their specific challenges, leveraging in-depth material science knowledge, and utilizing flexible manufacturing processes to deliver a product that is perfectly tailored, leading to superior long-term performance and efficiency. This collaborative approach ensures that the investment in insect proof mesh yields maximum operational benefits, whether it's for a specialized agricultural research facility or a large-scale industrial project with unique environmental constraints.

Manufacturer Comparison: Benchmarking Excellence in Insect Proof Mesh Production

Selecting the right manufacturer for insect proof mesh is a critical decision for B2B entities, impacting not only product performance and longevity but also overall project success and return on investment. While numerous suppliers exist, significant disparities in quality, technical expertise, and service distinguish leading manufacturers from the rest. Evaluating potential partners based on a comprehensive set of criteria is essential to ensure a reliable and effective supply chain. This comparison highlights the key differentiators that elevate a manufacturer to a position of trusted authority in the industry, implicitly positioning YJ Wiremesh as a premier choice.

1. Raw Material Sourcing and Purity:

A foundational difference lies in the commitment to using 100% virgin raw materials, such as high-grade HDPE resin, coupled with the highest quality UV stabilizers. Inferior manufacturers might use recycled materials or lower-grade compounds, compromising the mesh's strength, UV resistance, and overall service life. A reputable manufacturer will provide material safety data sheets (MSDS) and certificates of analysis (COA) for their raw inputs, ensuring transparency and adherence to international standards. This commitment to material purity directly correlates with the durability and performance of the final insect proof mesh.

2. Manufacturing Precision and Technological Investment:

Leading manufacturers invest heavily in state-of-the-art weaving looms, extrusion equipment, and quality control machinery. Precision weaving, often utilizing advanced leno weave technology, ensures consistent mesh count, uniform hole size, and superior structural stability. This contrasts with manufacturers using older equipment, which may produce inconsistent mesh openings, leading to compromised pest exclusion and reduced product lifespan. The integration of automated processes and real-time monitoring, similar to advanced CNC manufacturing, signifies a commitment to reducing defects and achieving peak operational efficiency, thereby ensuring the quality of every roll of insect net.

3. Stringent Quality Assurance and Certifications:

Authoritative manufacturers adhere to rigorous quality management systems, evidenced by certifications such as ISO 9001:2015. They conduct comprehensive in-house testing – including tensile strength, tear resistance, UV accelerated weathering, light transmission, and mesh count verification – using calibrated equipment and following international test standards (e.g., ASTM, ISO). Some may also hold product-specific certifications for environmental compliance (e.g., RoHS, REACH) or food-grade safety (e.g., FDA compliance for certain applications). The presence of such certifications and a robust QA department provides verifiable proof of product reliability and consistency, distinguishing them from producers who may offer lower prices but compromise on essential testing and quality checks.

4. Research and Development (R&D) Capabilities:

Pioneering manufacturers continuously invest in R&D to innovate and improve their insect proof mesh products. This includes developing new polymer formulations for enhanced UV resistance, optimizing weave patterns for better airflow/light transmission balance, or integrating novel functionalities like anti-static or antimicrobial properties. A strong R&D pipeline ensures that the manufacturer can offer cutting-edge solutions that address evolving industry challenges and specific client needs. This forward-thinking approach makes them a strategic partner for long-term projects and emerging market demands.

5. Customization and Technical Support:

The ability to provide bespoke insect proof mesh solutions tailored to unique project dimensions, specific pest challenges, or environmental conditions is a key differentiator. This requires a dedicated technical sales and engineering team capable of understanding complex requirements, offering expert advice on mesh selection, and guiding clients through customized production processes. Responsive pre-sales consultation and robust post-sales support, including installation guidance and troubleshooting, reflect a manufacturer's commitment to customer success. This level of service is crucial for large-scale agricultural operations or complex industrial bug netting installations.

6. Global Distribution and Logistics:

For B2B clients with international operations, a manufacturer with a well-established global distribution network and efficient logistics capabilities ensures timely and cost-effective delivery of insect proof mesh. This includes experience with international shipping regulations, customs procedures, and packaging optimization for long-distance transport, minimizing transit damage and delays for large volumes of outdoor bug net or head nets for bugs.

| Comparison Criterion | Leading Manufacturer (e.g., YJ Wiremesh) | Typical Competitor (Price-Focused) |

|---|---|---|

| Raw Material Quality | 100% Virgin HDPE with premium UV stabilizers; Certificates of Analysis provided. | Often recycled or lower-grade polymers; minimal or no UV stabilizers; inconsistent material purity. |

| Manufacturing Process | Advanced precision weaving (Leno weave), automated extrusion, consistent heat-setting. | Basic weaving, less consistent extrusion, potential for uneven mesh/weak points. |

| Quality Control & Certifications | ISO 9001 certified, comprehensive in-house testing (tensile, UV, tear, light transmission), adherence to ASTM/ISO. | Limited or no formal certifications; minimal internal testing; reliance on visual inspection. |

| Product Performance (Service Life) | Guaranteed 5-10+ years outdoor lifespan; consistent pest exclusion. | 1-3 years outdoor lifespan; rapid degradation, inconsistent pest exclusion. |

| Customization Capabilities | Extensive (custom mesh, widths, colors, special treatments like FR/Antimicrobial). | Limited to standard sizes and colors; little to no special treatment options. |

| Technical Support & Warranty | Dedicated technical team, comprehensive pre/post-sales support, robust warranty. | Basic sales support, minimal technical guidance, limited or no warranty. |

By critically evaluating these factors, B2B purchasers can ensure they partner with a manufacturer that not only supplies a product but also provides a comprehensive solution backed by expertise, quality, and dedicated support. This strategic selection leads to long-term operational resilience and maximizes the return on investment for their insect proof mesh applications.

Real-World Application Cases & Success Stories with Insect Proof Mesh

The theoretical advantages of insect proof mesh are best illustrated through real-world applications where its deployment has led to tangible, measurable benefits. These case studies underscore the effectiveness of advanced netting solutions in diverse operational contexts, from large-scale agriculture to critical public health initiatives.

Case Study 1: Large-Scale Greenhouse Complex in a Tropical Climate (Agriculture)

Client Profile: A major agricultural corporation operating a 50-hectare hydroponic greenhouse complex in Southeast Asia, specializing in high-value vegetable crops.

Challenge: The tropical climate resulted in severe infestations of whiteflies (Bemisia tabaci) and thrips (Frankliniella occidentalis), leading to significant crop losses (up to 30%) and a high reliance on weekly pesticide sprays. The high humidity also exacerbated fungal diseases.

Solution: YJ Wiremesh provided a customized insect proof mesh solution with a precise 50-mesh count, specifically engineered for optimal light transmission (90%) and airflow (rated at 400 CFM/sqm @ 0.1" WG) while effectively blocking the target pests. The mesh was integrated into all greenhouse vents and sidewalls, and also used for double-door entry systems. The material was virgin HDPE with enhanced UV stabilization (rated for 7+ years) to withstand intense tropical sun.

Results:

- Pest Reduction: Within three months, whitefly and thrips populations inside the greenhouses were reduced by over 95%, virtually eliminating pest-related crop damage.

- Pesticide Savings: The need for pesticide sprays dropped from weekly to bi-monthly, and eventually to only spot treatments for isolated issues, resulting in annual chemical cost savings of over $250,000.

- Yield Increase: Crop marketable yield increased by an average of 25% due to reduced pest damage and improved plant health, translating to millions in additional revenue.

- Labor Efficiency: Significant reduction in labor hours previously dedicated to spraying and pest scouting.

- Environmental Impact: Substantial reduction in chemical runoff, contributing to the farm's sustainable agriculture goals.

Case Study 2: Food Processing Facility Upgrade (Industrial Hygiene)

Client Profile: A large-scale bakery and snack food production facility in a metropolitan area, highly susceptible to fly and rodent ingress due to large bay doors and ventilation openings.

Challenge: Persistent issues with flies entering the production areas, leading to potential contamination risks, increased hygiene inspection failures, and ongoing pest control costs. Existing fly screens were inadequate.

Solution: YJ Wiremesh supplied custom-fabricated panels of durable stainless steel insect proof mesh (18x16 mesh, 0.25mm wire diameter), known for its robust construction and ease of cleaning, to replace traditional screens on all external openings, including loading docks and ventilation shafts. The mesh was chosen for its corrosion resistance and durability in a wash-down environment, ensuring it could withstand stringent cleaning protocols. Custom frames were designed for quick removal and maintenance.

Results:

- Zero Fly Ingress: Within weeks of installation, the facility reported a near-zero incidence of flies in production areas, significantly improving food safety and compliance.

- Reduced Pest Control Costs: Monthly pest control service calls for flies were reduced by 80%, leading to annual savings of approximately $15,000.

- Enhanced Compliance: Consistently passed stringent food safety audits, demonstrating superior hygiene controls.

- Operational Efficiency: Staff could now focus more on core production activities rather than pest mitigation, reducing the need for bug netting spot treatments.

Case Study 3: Community Malaria Prevention Program (Public Health)

Client Profile: A non-governmental organization (NGO) implementing a malaria prevention program in rural communities in sub-Saharan Africa.

Challenge: High incidence of malaria due to pervasive mosquito populations and limited access to chemical insecticides or treated bed nets. The community needed a sustainable, low-cost physical barrier solution for homes and clinics.

Solution: YJ Wiremesh collaborated to supply large rolls of UV-stabilized, durable insect proof mesh (20-mesh for mosquito exclusion) to be installed on windows and door frames of over 1,000 homes and local health clinics. Training was provided to local communities for proper installation and simple maintenance of the insect net.

Results:

- Disease Incidence Reduction: Initial data showed a statistically significant reduction (average 40%) in new malaria cases in the screened communities compared to control groups within the first year.

- Community Empowerment: The permanent nature of the mesh empowered communities to control mosquito populations themselves, reducing reliance on external aid for short-term solutions.

- Improved Sleep and Well-being: Residents reported better sleep quality due to reduced mosquito bites, enhancing overall health and productivity.

- Cost-Effectiveness: The long lifespan of the insect proof mesh made it a highly cost-effective intervention compared to repeated distribution of treated bed nets.

These cases exemplify how investing in high-quality insect proof mesh is not merely a purchase, but a strategic decision that yields profound and lasting benefits across various industries and societal sectors, proving its efficacy and value through demonstrable results and positive impacts on operational integrity, public health, and environmental sustainability.

Frequently Asked Questions (FAQs) About Insect Proof Mesh

Prospective B2B clients often have detailed questions regarding the selection, installation, and maintenance of insect proof mesh. Addressing these common inquiries provides clarity, builds trust, and streamlines the procurement process.

Q1: How do I choose the correct mesh size for my specific application?

A: Selecting the appropriate mesh size is critical for effective pest exclusion. It primarily depends on the specific insects you aim to block. For instance, common houseflies and mosquitoes typically require an 18x16 mesh (18 threads per inch in one direction, 16 in the other). For smaller agricultural pests such as whiteflies, aphids, and thrips, a finer insect proof mesh ranging from 30-mesh to 50-mesh is necessary. Very fine meshes (e.g., 80-mesh) might be considered for extreme exclusion of even smaller insects or spores, but these will significantly reduce airflow and light transmission. We recommend consulting our technical team with information on your target pests and environmental conditions. We can then provide a tailored recommendation based on our extensive experience and scientific data regarding insect morphology and behavior.

Q2: What is the typical lifespan of your Insect Proof Mesh, and what factors affect it?

A: Our high-quality insect proof mesh, manufactured from 100% virgin HDPE with advanced UV stabilization, is designed for exceptional longevity. Under normal outdoor conditions, you can expect a service life of 5 to 7 years. In regions with moderate sunlight and proper maintenance, it can often exceed 10 years. Key factors influencing lifespan include:

- UV Radiation Intensity: Prolonged exposure to intense direct sunlight accelerates degradation. Our advanced UV stabilizers mitigate this, but extreme conditions will still have an impact.

- Mechanical Stress: Constant rubbing, tearing, or impacts from wind, debris, or human activity can reduce lifespan.

- Chemical Exposure: While our meshes are highly chemical-resistant, prolonged exposure to aggressive chemicals not meant for agricultural use can affect durability.

- Installation Quality: Proper tensioning and secure fastening minimize flapping and stress points, extending the life of the bug netting.

Q3: Is your Insect Proof Mesh suitable for organic farming?

A: Absolutely. Our insect proof mesh is an ideal solution for organic farming. By providing a physical barrier against pests, it eliminates or drastically reduces the need for synthetic pesticides, aligning perfectly with organic certification requirements and sustainable agricultural practices. The mesh material itself (virgin HDPE) is inert and does not release harmful chemicals into the environment or crops. It supports integrated pest management (IPM) by focusing on prevention rather than chemical intervention, thereby fostering healthier ecosystems within and around the farm.

Q4: How should I install and maintain the insect proof mesh?

A: Proper installation is crucial for maximizing the effectiveness and lifespan of the insect proof mesh. Ensure the mesh is taut and securely fastened to frames or structures, minimizing gaps that pests could exploit. For greenhouses, ensure continuous sealing around all vents and entry points. Maintenance is generally straightforward:

- Regular Cleaning: Periodically spray the mesh with water to remove dust, pollen, or debris that might impede airflow or light transmission. For stubborn dirt, a mild soap solution can be used.

- Inspect for Damage: Routinely check for any tears, holes, or loose fastenings. Promptly repair any damage to maintain the integrity of the barrier.

- Winterization (if applicable): In regions with heavy snowfall, consider temporary removal or loosening of tension to prevent snow load damage, or ensure the supporting structure can bear the weight.

Q5: What are your typical lead times and delivery processes for large orders?

A: Lead times for insect proof mesh vary based on order volume, customization requirements, and current production schedules. For standard products, typical lead times range from 2-4 weeks. For highly customized orders or very large volumes, lead times may extend to 4-8 weeks. We maintain robust production capacities and efficient logistics partnerships to ensure timely delivery worldwide. We work closely with clients to establish realistic delivery schedules and can arrange for various shipping options (sea freight, air freight) to meet urgent project timelines. Our dedicated logistics team handles all necessary documentation and customs procedures to ensure a smooth, end-to-end delivery process, whether it's for an insect net shipment to a remote farm or a bulk order for head nets for bugs.

Q6: Do you offer a warranty for your Insect Proof Mesh products?

A: Yes, we stand by the quality and durability of our insect proof mesh. We offer a comprehensive limited warranty against manufacturing defects and premature material degradation due to UV exposure under normal use conditions. The specific warranty period varies by product type and application, typically ranging from 5 to 10 years, reflecting our confidence in the longevity of our UV-stabilized HDPE products. Detailed warranty terms and conditions are provided with each quotation and purchase agreement. Our commitment to quality ensures that your investment is protected and that the insect proof mesh delivers consistent, reliable performance throughout its intended service life. This commitment is a cornerstone of our trustworthiness and long-term partnerships with B2B clients globally.

Commitment to Quality, Trust, and Enduring Partnerships

In the highly competitive B2B landscape, the selection of a supplier for critical components like insect proof mesh transcends mere product specifications. It's about forging a partnership built on trust, demonstrated expertise, and a shared commitment to excellence. At YJ Wiremesh, our dedication to quality assurance is not just a procedural step; it's an ingrained philosophy that underpins every aspect of our operations, from initial raw material sourcing to final product delivery and beyond. Our manufacturing facilities operate under stringent ISO 9001:2015 certified quality management systems, ensuring that every batch of insect proof mesh adheres to the highest international standards for consistency, performance, and environmental compliance. This systematic approach guarantees traceability of materials, adherence to precise manufacturing tolerances, and rigorous inspection at every stage, providing our clients with unparalleled confidence in our product's reliability and durability. We conduct comprehensive internal testing, mirroring industry benchmarks such as ASTM and ISO, covering critical parameters including tensile strength, tear resistance, UV degradation, airflow permeability, and light transmission. These tests are performed by certified technicians using state-of-the-art equipment, and detailed reports are available upon request, offering complete transparency.

Our commitment to our clients extends far beyond product delivery. We understand that investing in insect proof mesh is a long-term strategic decision, and we back that investment with a robust warranty program. Our comprehensive warranties, typically ranging from 5 to 10 years depending on the specific product and application, cover manufacturing defects and premature material degradation under normal usage conditions, giving our clients peace of mind and protecting their operational investments. This warranty is a testament to the superior quality of our virgin HDPE materials and our advanced manufacturing processes that integrate high levels of UV stabilizers for extended outdoor performance. Furthermore, our dedicated customer support infrastructure ensures that technical assistance, product inquiries, and logistical coordination are handled with efficiency and professionalism. Our global service network allows us to provide responsive support to clients across diverse geographical locations, ensuring that whether it's a large-scale agricultural project requiring tailored insect net solutions or a public health initiative distributing head nets for bugs, seamless assistance is always available. We pride ourselves on building enduring relationships with our B2B partners, acting not just as a supplier but as a trusted technical consultant, providing insights, customized solutions, and after-sales support that contribute directly to our clients' success and operational resilience. This holistic approach to client engagement solidifies our position as a leader in the advanced insect proof mesh market, fostering long-term value and mutual growth.

Further Reading and Citations

For those seeking to delve deeper into the scientific and industrial aspects of protective netting and integrated pest management, the following resources provide valuable insights:

- Food and Agriculture Organization of the United Nations (FAO). "Good Agricultural Practices (GAPs) for Protected Cultivation." This publication often includes detailed sections on physical barriers and insect net use in horticulture. https://www.fao.org/land-water/overview/sustainable-intensification/good-agricultural-practices-gaps/en/

- Journal of Economic Entomology. "Advances in Insect Exclusion Technologies for Crop Protection." Academic journals like this frequently publish peer-reviewed studies on the efficacy of various insect proof mesh types against specific pests. Access typically requires institutional subscription or pay-per-article. Example journal link: https://academic.oup.com/jee

- Plastics in Agriculture. Reviews and analyses of polymer applications in agriculture, including the material science behind durable bug netting and UV stability. Search for relevant articles on reputable scientific databases (e.g., ScienceDirect, SpringerLink). Example resource: https://www.sciencedirect.com/topics/engineering/plastics-in-agriculture

These resources offer authoritative perspectives on the market dynamics, technical specifications, and application efficacy of insect proof mesh solutions, serving as valuable references for professionals seeking in-depth knowledge and validated research.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025