Durable Stainless Steel Filters | Precision Wire Mesh Solutions

Introduction to Advanced Filtration Systems

In the intricate landscape of modern industrial operations, efficient and reliable filtration is not merely a component but a critical determinant of product quality, operational safety, and environmental compliance. Among the myriad filtration solutions available, stainless steel filters stand out for their unparalleled durability, corrosion resistance, and high-temperature performance. These sophisticated systems are engineered to meet the rigorous demands of diverse sectors, providing robust solutions for liquid, gas, and solid-particle separation.

This comprehensive overview delves into the core aspects of stainless steel filtration technology, from manufacturing intricacies and technical specifications to real-world applications and strategic vendor considerations. Our goal is to equip B2B decision-makers and engineering professionals with the knowledge required to make informed choices for their critical filtration needs.

Current Industry Trends in Filtration Technology

The filtration industry is experiencing dynamic shifts, driven by escalating environmental regulations, demands for higher purity standards, and the imperative for sustainable operations. Key trends include:

- Advanced Materials Science: Development of novel alloys and composites to enhance filter performance under extreme conditions (e.g., higher temperatures, more aggressive chemicals).

- Smart Filtration Systems: Integration of IoT sensors and AI-driven analytics for real-time monitoring of filter performance, predictive maintenance, and optimized replacement cycles.

- Sustainable Solutions: Focus on reusable, cleanable, and recyclable filter media to minimize waste and reduce operational expenditure. The superior cleanability of stainless steel filters aligns perfectly with this trend.

- Miniaturization and Modularity: Designing compact, modular filter units that offer flexibility in installation and scalability for various process volumes.

- Enhanced Efficiency: Continuous innovation in filter design to achieve higher filtration efficiency (up to absolute ratings) with lower pressure drop, leading to significant energy savings.

These trends underscore a commitment to both operational excellence and environmental stewardship, positioning high-performance filtration solutions as central to industrial progress.

The Manufacturing Process of Stainless Steel Filters: From Raw Material to Precision Filtration

The creation of high-quality stainless steel filters is a multi-stage process demanding precision engineering, advanced material science, and stringent quality control. Here’s a detailed look at the typical manufacturing flow:

1. Material Selection & Preparation

The foundation of any superior filter is its material. For stainless steel filters, this typically involves grades like 304, 316, or specialized alloys such as Duplex stainless steel, chosen for their specific corrosion resistance, temperature tolerance, and mechanical strength. Materials are sourced in sheet, wire, or powder forms, adhering to international standards like ASTM A240 for steel sheets or ASTM A580 for wire.

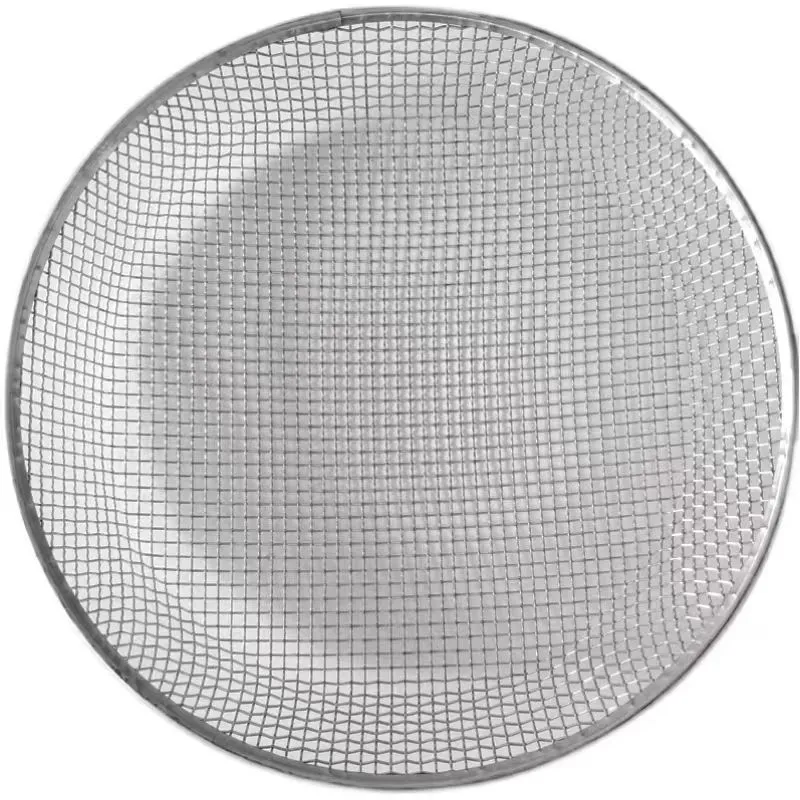

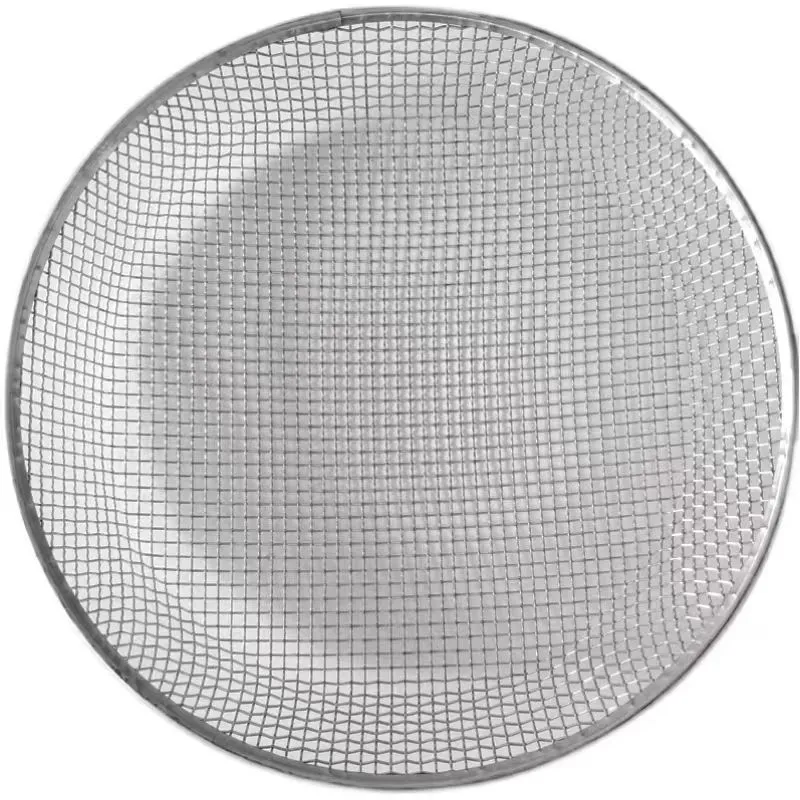

2. Wire Drawing & Weaving (for Wire Mesh Filters)

For wire mesh filter products, precision wire drawing reduces stainless steel rods to the desired wire diameter. These wires are then woven on specialized looms to create various mesh patterns (e.g., plain weave, twill weave, Dutch weave). The weaving process dictates the pore size and filtration efficiency. Advanced wire mesh filter manufacturers utilize automated weaving machines to ensure uniform mesh openings and structural integrity.

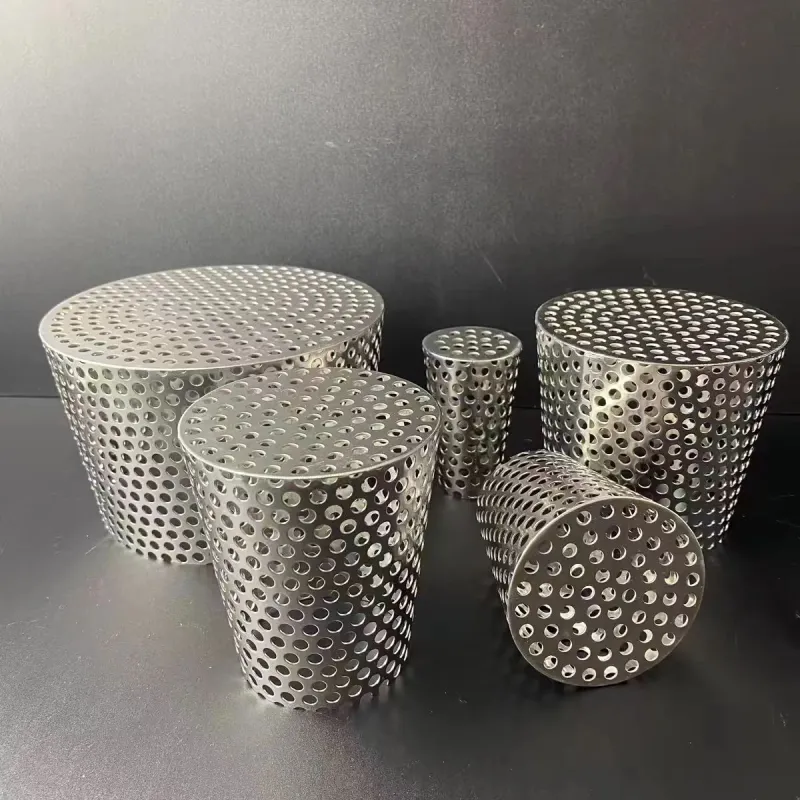

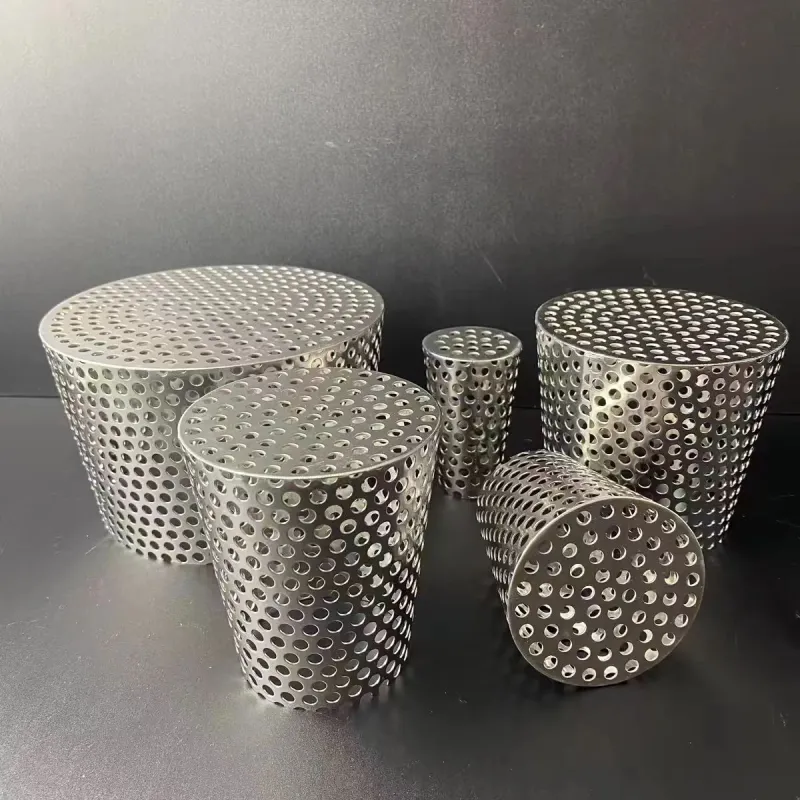

3. Perforation & Sintering (for Perforated/Sintered Filters)

Alternatively, for perforated filters, stainless steel sheets undergo precision punching or laser cutting to create specific hole patterns. For sintered filters, stainless steel powder or multi-layered woven mesh is compacted and then heated to a high temperature below its melting point. This sintering process creates a strong, porous structure with controlled pore sizes, offering exceptional mechanical strength and thermal stability.

4. Forming & Fabrication (e.g., CNC Machining, Welding)

Once the primary filter media is created, it's formed into the desired shape—cartridges, discs, cones, or cylinders—using processes like rolling, bending, and pressing. Precision CNC machining is often employed for end caps, flanges, and structural components to ensure exact dimensions and fit. Welding (TIG, laser, or resistance welding) is then used to join components, ensuring robust, leak-free construction. All welding must conform to standards like AWS D1.6 (Structural Welding Code – Stainless Steel).

5. Cleaning & Surface Treatment

Post-fabrication, filters undergo thorough cleaning to remove manufacturing residues, oils, and contaminants. This often involves ultrasonic cleaning, degreasing, and passivation (e.g., ASTM A967/A380) to enhance corrosion resistance and ensure cleanliness, especially for critical applications in food & beverage or pharmaceutical industries.

6. Quality Control & Testing

Rigorous testing is paramount. This includes dimensional checks, visual inspection for defects, burst pressure tests, bubble point tests (for pore size uniformity), and flow rate tests. Filters must meet specified filtration efficiency ratings (e.g., Beta ratio according to ISO 16889) and comply with industry standards such as ISO 2941, ISO 2942, ISO 2943, and ANSI/AWWA standards for water treatment applications. Expected service life for a well-maintained 304 stainless steel filter screen can range from 5 to 15 years, depending on the application severity and material compatibility.

7. Packaging & Delivery

Finished filters are carefully packaged to prevent damage during transit and delivered with full documentation, including material certifications and test reports.

Technical Specifications and Parameters

Understanding the technical specifications of stainless steel filters is crucial for optimal system integration and performance. Here's a table outlining typical parameters for a 304 Stainless Steel Filter Screen:

Product Specification Table: 304 Stainless Steel Filter Screen

| Parameter | Specification / Value | Standard / Description |

|---|---|---|

| Material Grade | AISI 304 Stainless Steel | Excellent corrosion resistance, suitable for general industrial applications. |

| Mesh Count Range | 2 to 635 mesh per inch | Determines filtration precision; finer mesh for smaller particles. |

| Wire Diameter | 0.02 mm to 4.0 mm (0.0008" to 0.157") | Affects strength, open area, and flow rate. |

| Pore Size (Nominal) | 20 microns to 10 mm | Critical for particle retention; can be customized. |

| Operating Temperature | Up to 800°C (1472°F) | High-temperature resistance is a key advantage of stainless steel. |

| Corrosion Resistance | Excellent against atmospheric, freshwater, and various chemicals. | Superior to carbon steel, good in non-chloride environments. |

| Cleanability | Easy to clean via backwashing, ultrasonic, or chemical methods. | Extends service life and reduces operational costs. |

| Tensile Strength | 515 - 620 MPa (75 - 90 ksi) | Indicates mechanical robustness and resistance to deformation. |

| Form Factor | Sheets, rolls, discs, cylinders, cartridges, custom shapes | Versatility for various filtration equipment designs. |

Key Technical Advantages of Stainless Steel Filtration

The selection of filtration media significantly impacts operational efficiency and total cost of ownership. Stainless steel filters offer several distinct technical advantages:

- Superior Corrosion Resistance: Stainless steel, particularly grades like 304 and 316, exhibits exceptional resistance to oxidation and various corrosive media, ensuring long-term performance even in harsh chemical environments. This translates to reduced maintenance and replacement costs.

- High Temperature and Pressure Tolerance: Unlike polymer-based filters, stainless steel maintains its structural integrity and filtration efficiency at elevated temperatures (e.g., up to 800°C for 304 SS) and under high differential pressures, making them ideal for demanding processes.

- Excellent Mechanical Strength: The inherent strength of stainless steel provides robust filter elements resistant to vibration, pressure spikes, and mechanical stress, crucial for continuous operation and preventing media migration.

- Cleanability and Reusability: Most stainless steel filter elements are designed for easy cleaning via backwashing, ultrasonic baths, or chemical flushing. This reusability significantly reduces waste generation and lowers operational expenditure compared to disposable alternatives.

- Precise and Stable Pore Size: Through advanced weaving or sintering processes, stainless steel filters can achieve highly accurate and consistent pore sizes, ensuring reliable and repeatable filtration performance. This is critical for applications requiring strict particle control.

- Energy Saving Potential: Their durable construction and capacity for high flow rates with minimal pressure drop contribute to energy savings by reducing pump load and optimizing system efficiency.

- Broad Chemical Compatibility: Stainless steel is compatible with a wide array of chemicals, solvents, and fluids, offering versatility across numerous industrial processes.

- Hygienic Properties: The smooth, non-porous surface of stainless steel inhibits bacterial growth and is easy to sanitize, making it suitable for sensitive applications such as food & beverage and pharmaceuticals.

Application Scenarios and Target Industries

The robust characteristics of stainless steel wire mesh filter systems make them indispensable across a broad spectrum of industries, providing critical filtration solutions in challenging environments.

- Petrochemical Industry: Filtration of crude oil, natural gas, refining products, catalysts, and quench water. Their corrosion resistance is vital for handling aggressive hydrocarbons and chemicals.

- Chemical Processing: Separation of solids from corrosive liquids, catalyst recovery, and purification of specialty chemicals. High temperature and pressure capabilities are frequently utilized.

- Power Generation: Pre-filtration for boiler feed water, cooling water systems, and lubricant oil filtration in turbines, ensuring uninterrupted operation and preventing scale buildup.

- Water Supply & Drainage: Municipal and industrial water treatment, pre-filtration for reverse osmosis (RO) systems, wastewater effluent treatment, and desalination plants.

- Food & Beverage: Clarification of edible oils, fruit juices, brewing liquids, and dairy products. The hygienic properties and ease of cleaning are paramount for preventing contamination.

- Pharmaceuticals: Sterilization filtration, active pharmaceutical ingredient (API) processing, and particulate removal from process fluids where cleanliness and reusability are critical. Compliance with FDA standards is a common requirement.

- Metallurgy & Mining: Slurry dewatering, filtration of molten metals (for certain applications), and hydraulic oil purification for heavy machinery.

- Automotive: Fuel filtration, hydraulic fluid purification, and air intake filtration for engine protection.

- Aerospace: Hydraulic system filtration, fuel filtration, and air filtration for sensitive components, where extreme reliability and performance are non-negotiable.

Vendor Comparison and Selection Criteria

Choosing the right wire mesh filter manufacturers for your stainless steel filters is a strategic decision that impacts long-term operational costs and system reliability. Consider the following criteria:

Key Vendor Evaluation Factors:

- Technical Expertise & R&D: Assess their ability to understand complex filtration challenges and offer innovative, effective solutions. Look for a track record in developing specialized designs.

- Manufacturing Capabilities: Evaluate their production capacity, precision engineering, and adherence to quality standards (e.g., ISO 9001 certification).

- Product Portfolio: A diverse range of filter types (wire mesh, sintered, perforated) and material grades indicates broader expertise and ability to meet varied needs.

- Quality Control & Certifications: Verify adherence to international standards (e.g., ISO, ANSI, ASTM) and specific industry certifications (e.g., FDA compliance for food/pharma).

- Customization Capabilities: The ability to design and manufacture bespoke filters to exact specifications is crucial for unique or niche applications.

- After-Sales Support & Service: Availability of technical support, spare parts, cleaning recommendations, and warranty terms.

- Lead Time & Logistics: Efficiency in production and delivery to meet project timelines.

- Industry Experience & Reputation: Years in service, client testimonials, and case studies reflecting successful projects in your specific industry.

Comparison Table: Filtration Media Performance

| Feature | Stainless Steel Filters | Polymer (e.g., Polypropylene) | Ceramic Filters |

|---|---|---|---|

| Max Temperature | Up to 800°C | ~80-100°C | Up to 1000°C |

| Corrosion Resistance | Excellent (broad range) | Good (specific chemicals) | Excellent (highly inert) |

| Mechanical Strength | Very High | Low to Medium | High (brittle) |

| Cleanability/Reusability | Excellent (washable) | Limited (often disposable) | Good (backwash/thermal) |

| Pore Size Precision | Very High | Medium to High | High |

| Cost (per unit) | Medium to High | Low | High |

| Total Cost of Ownership | Low (due to reusability, longevity) | High (frequent replacement) | Medium (durability) |

Customized Filtration Solutions

Every industrial process has unique filtration requirements that off-the-shelf solutions may not fully address. This is where customized stainless steel filters become invaluable. Leading wire mesh filter manufacturers excel at providing bespoke designs tailored to specific operational parameters, fluid characteristics, and system interfaces.

Customization options include:

- Material Grade Selection: Beyond standard 304 and 316L, options like 310S, 904L, Duplex, or Super Duplex stainless steel can be specified for extreme corrosion or high-temperature resistance.

- Mesh Count & Weave Pattern: Tailoring the wire diameter, mesh count, and weave style (e.g., plain, twill, Dutch, reverse Dutch) to achieve precise micron ratings and flow characteristics for specific particle sizes and viscosities.

- Filter Element Geometry: Manufacturing custom dimensions, shapes (e.g., specific cone angles, multi-layered cylindrical cartridges, complex disc configurations), and connection types (e.g., threaded, flanged, custom quick-connect) to seamlessly integrate into existing systems.

- Structural Reinforcement: Adding internal or external support structures to withstand high differential pressures, prevent deformation, and extend service life in demanding applications.

- Surface Treatments: Specialized passivation, electropolishing, or coating for enhanced cleanliness, reduced particle adhesion, or improved corrosion resistance in ultra-pure or hygienic processes.

- Multi-Layer & Sintered Construction: Combining multiple layers of mesh with different pore sizes or utilizing sintered metal powder for graded filtration, exceptional strength, and precise absolute filtration ratings.

Engaging with manufacturers early in the design phase allows for collaborative engineering, ensuring that the custom filter solution not only meets performance targets but also optimizes cost-effectiveness and ease of maintenance.

Real-World Application Case Studies

The practical advantages of stainless steel filters are best demonstrated through successful deployments:

Case Study 1: Enhanced Catalyst Recovery in Petrochemical Plant

A major petrochemical company faced challenges with catalyst loss and frequent downtime due to clogging in their polymerization unit's existing filtration system. The high operating temperature (250°C) and corrosive media degraded polymeric filters rapidly. Our team implemented custom-designed, multi-layered 316L stainless steel wire mesh filter cartridges. These filters provided superior heat and corrosion resistance, significantly reducing catalyst loss by 15% and extending filter service life from 3 months to over 18 months, leading to a 40% reduction in maintenance costs and a 5% increase in production uptime. The client praised the exceptional durability and long-term cost savings.

Case Study 2: High-Purity Water Filtration for Pharmaceutical Manufacturing

A leading pharmaceutical firm required an ultra-clean, reusable filtration solution for their purified water system. Existing filters suffered from media migration and could not withstand repeated steam sterilization (SIP) cycles effectively. We engineered electro-polished 304L stainless steel pleated filter cartridges with an absolute micron rating of 0.5 µm. These filters met stringent FDA and USP Class VI requirements, demonstrated excellent performance during SIP cycles, and allowed for repeated backwashing without compromising integrity. The client achieved consistent water purity and a substantial reduction in consumable waste, aligning with their sustainability goals.

Case Study 3: Optimized Hydraulic Oil Filtration in Heavy Machinery

A large-scale mining operation struggled with premature wear of hydraulic components due to inadequate filtration of hydraulic oils, especially under high-pressure conditions and significant particle loads. Disposable filters required frequent changes, impacting operational continuity. We supplied robust sintered 316 stainless steel filter elements, designed for high differential pressure tolerance and excellent dirt-holding capacity. These filters proved exceptionally effective in removing fine particulate contamination, extending the lifespan of hydraulic pumps and valves by over 30%, and drastically reducing filter replacement frequency by 70%. The client reported enhanced equipment reliability and significant savings on spare parts and labor.

Ensuring Trust: Certifications and Authoritative References

Establishing trust in the B2B sector hinges on verifiable credentials and a commitment to quality. Our manufacturing processes and products are underpinned by a robust framework of certifications and adherence to authoritative industry standards:

- ISO 9001:2015 Certified: Our Quality Management System is internationally recognized, ensuring consistent product quality, efficiency, and continuous improvement in all stages from design to delivery.

- Material Certifications: All raw materials, especially stainless steel, are supplied with Mill Test Certificates (MTCs) conforming to ASTM, DIN, and EN standards, guaranteeing material composition and mechanical properties.

- Compliance with Industry Standards: Our stainless steel filters meet or exceed relevant performance and safety standards, including:

- ISO 2941, 2942, 2943: For hydraulic filter elements' collapse/burst resistance, fabrication integrity, and material compatibility.

- ISO 16889: Multi-pass test for evaluating filtration performance (Beta Ratio).

- FDA (21 CFR 177) Compliance: For materials used in food, beverage, and pharmaceutical contact applications, where applicable.

- ANSI/AWWA Standards: For water treatment and potable water applications.

- Partnerships & Client Testimonials: We have successfully served a global clientele, including Fortune 500 companies in petrochemicals, power generation, and food processing, for over two decades. Testimonials and repeat business underscore our reliability and commitment to customer satisfaction.

- Extensive In-house Testing: Our facilities are equipped for comprehensive testing, including pressure differential, flow rate, particle retention efficiency, and metallurgical analysis, ensuring every product batch meets specified performance parameters.

Frequently Asked Questions (FAQ)

Q1: What is the typical service life of a stainless steel filter?

A1: The service life of a stainless steel filter is significantly longer than disposable filters, typically ranging from 5 to 15 years, or even more, depending on the application severity, frequency of cleaning, and material compatibility with the process fluid. Proper maintenance can extend this considerably.

Q2: How do I choose the correct micron rating for my application?

A2: The optimal micron rating depends on the size of the particles you need to remove, the required purity level of the fluid, and potential downstream equipment protection. Our technical team can assist you with this selection based on your specific process data and objectives.

Q3: Are these filters cleanable? If so, how?

A3: Yes, most stainless steel filters are highly cleanable and reusable. Common cleaning methods include backwashing with process fluid or water, ultrasonic cleaning, or chemical cleaning with appropriate solvents. The specific method depends on the contaminant and filter construction.

Q4: Can these filters withstand corrosive chemicals?

A4: Yes, stainless steel is known for its excellent corrosion resistance. For highly aggressive chemicals, we offer filters made from specific grades like 316L, Duplex, or Super Duplex stainless steel, which provide enhanced resistance to chlorides and other potent corrosive agents. Material compatibility should always be verified for critical applications.

Q5: What are the typical lead times for custom stainless steel filters?

A5: Lead times vary based on design complexity, material availability, and order volume. For standard products, lead times are typically 2-4 weeks. For custom-engineered solutions, lead times can range from 4-8 weeks from drawing approval. We work closely with clients to meet project deadlines and offer expedited services where feasible.

Order & Support Information

We are committed to providing exceptional service throughout the entire customer journey, from initial inquiry to long-term operational support.

Lead Time & Fulfillment

Our streamlined manufacturing process and robust supply chain enable competitive lead times. Standard orders typically ship within 2-4 weeks. For custom or high-volume orders, specific timelines will be provided upon consultation and design finalization, ensuring transparent project planning. We offer flexible shipping options to accommodate urgent requirements and global logistics.

Warranty Commitments

All our stainless steel wire mesh filter products come with a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. The standard warranty period is 12 months from the date of installation or 18 months from the date of shipment, whichever comes first. Extended warranty options are available for specific projects.

Customer Support & After-Sales Service

Our dedicated team of filtration experts is available to provide unparalleled support:

- Technical Consultation: Assistance with filter selection, system integration, and optimization.

- Troubleshooting: Expert guidance for resolving operational issues and maximizing filter performance.

- Maintenance & Cleaning Advice: Best practices for extending filter life and maintaining efficiency.

- Spare Parts: Prompt availability of replacement parts and accessories.

- Contact Us: For inquiries, quotes, or support, please visit our website at www.yjwiremesh.com or reach out to our sales and technical support teams.

Conclusion

The demand for reliable, high-performance filtration solutions continues to grow across all industrial sectors. Stainless steel filters represent a cornerstone of this demand, offering an unmatched combination of durability, chemical resistance, high-temperature capability, and reusability. By investing in these advanced filtration systems, businesses can achieve higher operational efficiencies, reduce maintenance costs, ensure product purity, and comply with increasingly stringent environmental regulations.

Partnering with a knowledgeable and experienced manufacturer who can provide both standard and customized solutions, backed by robust quality control and comprehensive after-sales support, is key to leveraging the full potential of stainless steel filtration technology for your specific needs.

References

- ASTM International. (2023). Standards for Stainless Steel. Available at: www.astm.org

- International Organization for Standardization (ISO). (2022). Hydraulic fluid power - Filter elements - Methods of test for verifying performance. Available at: www.iso.org

- Food and Drug Administration (FDA). (2023). Code of Federal Regulations Title 21 - Food and Drugs. Available at: www.fda.gov

- American Water Works Association (AWWA). (2023). Water Treatment Plant Design Standards. Available at: www.awwa.org

- ASM International. (2020). ASM Handbook Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025

Durable Stainless Steel Filters | Precision Wire Mesh Solutions

Introduction to Advanced Filtration Systems

In the intricate landscape of modern industrial operations, efficient and reliable filtration is not merely a component but a critical determinant of product quality, operational safety, and environmental compliance. Among the myriad filtration solutions available, stainless steel filters stand out for their unparalleled durability, corrosion resistance, and high-temperature performance. These sophisticated systems are engineered to meet the rigorous demands of diverse sectors, providing robust solutions for liquid, gas, and solid-particle separation.

This comprehensive overview delves into the core aspects of stainless steel filtration technology, from manufacturing intricacies and technical specifications to real-world applications and strategic vendor considerations. Our goal is to equip B2B decision-makers and engineering professionals with the knowledge required to make informed choices for their critical filtration needs.

Current Industry Trends in Filtration Technology

The filtration industry is experiencing dynamic shifts, driven by escalating environmental regulations, demands for higher purity standards, and the imperative for sustainable operations. Key trends include:

- Advanced Materials Science: Development of novel alloys and composites to enhance filter performance under extreme conditions (e.g., higher temperatures, more aggressive chemicals).

- Smart Filtration Systems: Integration of IoT sensors and AI-driven analytics for real-time monitoring of filter performance, predictive maintenance, and optimized replacement cycles.

- Sustainable Solutions: Focus on reusable, cleanable, and recyclable filter media to minimize waste and reduce operational expenditure. The superior cleanability of stainless steel filters aligns perfectly with this trend.

- Miniaturization and Modularity: Designing compact, modular filter units that offer flexibility in installation and scalability for various process volumes.

- Enhanced Efficiency: Continuous innovation in filter design to achieve higher filtration efficiency (up to absolute ratings) with lower pressure drop, leading to significant energy savings.

These trends underscore a commitment to both operational excellence and environmental stewardship, positioning high-performance filtration solutions as central to industrial progress.

The Manufacturing Process of Stainless Steel Filters: From Raw Material to Precision Filtration

The creation of high-quality stainless steel filters is a multi-stage process demanding precision engineering, advanced material science, and stringent quality control. Here’s a detailed look at the typical manufacturing flow:

1. Material Selection & Preparation

The foundation of any superior filter is its material. For stainless steel filters, this typically involves grades like 304, 316, or specialized alloys such as Duplex stainless steel, chosen for their specific corrosion resistance, temperature tolerance, and mechanical strength. Materials are sourced in sheet, wire, or powder forms, adhering to international standards like ASTM A240 for steel sheets or ASTM A580 for wire.

2. Wire Drawing & Weaving (for Wire Mesh Filters)

For wire mesh filter products, precision wire drawing reduces stainless steel rods to the desired wire diameter. These wires are then woven on specialized looms to create various mesh patterns (e.g., plain weave, twill weave, Dutch weave). The weaving process dictates the pore size and filtration efficiency. Advanced wire mesh filter manufacturers utilize automated weaving machines to ensure uniform mesh openings and structural integrity.

3. Perforation & Sintering (for Perforated/Sintered Filters)

Alternatively, for perforated filters, stainless steel sheets undergo precision punching or laser cutting to create specific hole patterns. For sintered filters, stainless steel powder or multi-layered woven mesh is compacted and then heated to a high temperature below its melting point. This sintering process creates a strong, porous structure with controlled pore sizes, offering exceptional mechanical strength and thermal stability.

4. Forming & Fabrication (e.g., CNC Machining, Welding)

Once the primary filter media is created, it's formed into the desired shape—cartridges, discs, cones, or cylinders—using processes like rolling, bending, and pressing. Precision CNC machining is often employed for end caps, flanges, and structural components to ensure exact dimensions and fit. Welding (TIG, laser, or resistance welding) is then used to join components, ensuring robust, leak-free construction. All welding must conform to standards like AWS D1.6 (Structural Welding Code – Stainless Steel).

5. Cleaning & Surface Treatment

Post-fabrication, filters undergo thorough cleaning to remove manufacturing residues, oils, and contaminants. This often involves ultrasonic cleaning, degreasing, and passivation (e.g., ASTM A967/A380) to enhance corrosion resistance and ensure cleanliness, especially for critical applications in food & beverage or pharmaceutical industries.

6. Quality Control & Testing

Rigorous testing is paramount. This includes dimensional checks, visual inspection for defects, burst pressure tests, bubble point tests (for pore size uniformity), and flow rate tests. Filters must meet specified filtration efficiency ratings (e.g., Beta ratio according to ISO 16889) and comply with industry standards such as ISO 2941, ISO 2942, ISO 2943, and ANSI/AWWA standards for water treatment applications. Expected service life for a well-maintained 304 stainless steel filter screen can range from 5 to 15 years, depending on the application severity and material compatibility.

7. Packaging & Delivery

Finished filters are carefully packaged to prevent damage during transit and delivered with full documentation, including material certifications and test reports.

Technical Specifications and Parameters

Understanding the technical specifications of stainless steel filters is crucial for optimal system integration and performance. Here's a table outlining typical parameters for a 304 Stainless Steel Filter Screen:

Product Specification Table: 304 Stainless Steel Filter Screen

| Parameter | Specification / Value | Standard / Description |

|---|---|---|

| Material Grade | AISI 304 Stainless Steel | Excellent corrosion resistance, suitable for general industrial applications. |

| Mesh Count Range | 2 to 635 mesh per inch | Determines filtration precision; finer mesh for smaller particles. |

| Wire Diameter | 0.02 mm to 4.0 mm (0.0008" to 0.157") | Affects strength, open area, and flow rate. |

| Pore Size (Nominal) | 20 microns to 10 mm | Critical for particle retention; can be customized. |

| Operating Temperature | Up to 800°C (1472°F) | High-temperature resistance is a key advantage of stainless steel. |

| Corrosion Resistance | Excellent against atmospheric, freshwater, and various chemicals. | Superior to carbon steel, good in non-chloride environments. |

| Cleanability | Easy to clean via backwashing, ultrasonic, or chemical methods. | Extends service life and reduces operational costs. |

| Tensile Strength | 515 - 620 MPa (75 - 90 ksi) | Indicates mechanical robustness and resistance to deformation. |

| Form Factor | Sheets, rolls, discs, cylinders, cartridges, custom shapes | Versatility for various filtration equipment designs. |

Key Technical Advantages of Stainless Steel Filtration

The selection of filtration media significantly impacts operational efficiency and total cost of ownership. Stainless steel filters offer several distinct technical advantages:

- Superior Corrosion Resistance: Stainless steel, particularly grades like 304 and 316, exhibits exceptional resistance to oxidation and various corrosive media, ensuring long-term performance even in harsh chemical environments. This translates to reduced maintenance and replacement costs.

- High Temperature and Pressure Tolerance: Unlike polymer-based filters, stainless steel maintains its structural integrity and filtration efficiency at elevated temperatures (e.g., up to 800°C for 304 SS) and under high differential pressures, making them ideal for demanding processes.

- Excellent Mechanical Strength: The inherent strength of stainless steel provides robust filter elements resistant to vibration, pressure spikes, and mechanical stress, crucial for continuous operation and preventing media migration.

- Cleanability and Reusability: Most stainless steel filter elements are designed for easy cleaning via backwashing, ultrasonic baths, or chemical flushing. This reusability significantly reduces waste generation and lowers operational expenditure compared to disposable alternatives.

- Precise and Stable Pore Size: Through advanced weaving or sintering processes, stainless steel filters can achieve highly accurate and consistent pore sizes, ensuring reliable and repeatable filtration performance. This is critical for applications requiring strict particle control.

- Energy Saving Potential: Their durable construction and capacity for high flow rates with minimal pressure drop contribute to energy savings by reducing pump load and optimizing system efficiency.

- Broad Chemical Compatibility: Stainless steel is compatible with a wide array of chemicals, solvents, and fluids, offering versatility across numerous industrial processes.

- Hygienic Properties: The smooth, non-porous surface of stainless steel inhibits bacterial growth and is easy to sanitize, making it suitable for sensitive applications such as food & beverage and pharmaceuticals.

Application Scenarios and Target Industries

The robust characteristics of stainless steel wire mesh filter systems make them indispensable across a broad spectrum of industries, providing critical filtration solutions in challenging environments.

- Petrochemical Industry: Filtration of crude oil, natural gas, refining products, catalysts, and quench water. Their corrosion resistance is vital for handling aggressive hydrocarbons and chemicals.

- Chemical Processing: Separation of solids from corrosive liquids, catalyst recovery, and purification of specialty chemicals. High temperature and pressure capabilities are frequently utilized.

- Power Generation: Pre-filtration for boiler feed water, cooling water systems, and lubricant oil filtration in turbines, ensuring uninterrupted operation and preventing scale buildup.

- Water Supply & Drainage: Municipal and industrial water treatment, pre-filtration for reverse osmosis (RO) systems, wastewater effluent treatment, and desalination plants.

- Food & Beverage: Clarification of edible oils, fruit juices, brewing liquids, and dairy products. The hygienic properties and ease of cleaning are paramount for preventing contamination.

- Pharmaceuticals: Sterilization filtration, active pharmaceutical ingredient (API) processing, and particulate removal from process fluids where cleanliness and reusability are critical. Compliance with FDA standards is a common requirement.

- Metallurgy & Mining: Slurry dewatering, filtration of molten metals (for certain applications), and hydraulic oil purification for heavy machinery.

- Automotive: Fuel filtration, hydraulic fluid purification, and air intake filtration for engine protection.

- Aerospace: Hydraulic system filtration, fuel filtration, and air filtration for sensitive components, where extreme reliability and performance are non-negotiable.

Vendor Comparison and Selection Criteria

Choosing the right wire mesh filter manufacturers for your stainless steel filters is a strategic decision that impacts long-term operational costs and system reliability. Consider the following criteria:

Key Vendor Evaluation Factors:

- Technical Expertise & R&D: Assess their ability to understand complex filtration challenges and offer innovative, effective solutions. Look for a track record in developing specialized designs.

- Manufacturing Capabilities: Evaluate their production capacity, precision engineering, and adherence to quality standards (e.g., ISO 9001 certification).

- Product Portfolio: A diverse range of filter types (wire mesh, sintered, perforated) and material grades indicates broader expertise and ability to meet varied needs.

- Quality Control & Certifications: Verify adherence to international standards (e.g., ISO, ANSI, ASTM) and specific industry certifications (e.g., FDA compliance for food/pharma).

- Customization Capabilities: The ability to design and manufacture bespoke filters to exact specifications is crucial for unique or niche applications.

- After-Sales Support & Service: Availability of technical support, spare parts, cleaning recommendations, and warranty terms.

- Lead Time & Logistics: Efficiency in production and delivery to meet project timelines.

- Industry Experience & Reputation: Years in service, client testimonials, and case studies reflecting successful projects in your specific industry.

Comparison Table: Filtration Media Performance

| Feature | Stainless Steel Filters | Polymer (e.g., Polypropylene) | Ceramic Filters |

|---|---|---|---|

| Max Temperature | Up to 800°C | ~80-100°C | Up to 1000°C |

| Corrosion Resistance | Excellent (broad range) | Good (specific chemicals) | Excellent (highly inert) |

| Mechanical Strength | Very High | Low to Medium | High (brittle) |

| Cleanability/Reusability | Excellent (washable) | Limited (often disposable) | Good (backwash/thermal) |

| Pore Size Precision | Very High | Medium to High | High |

| Cost (per unit) | Medium to High | Low | High |

| Total Cost of Ownership | Low (due to reusability, longevity) | High (frequent replacement) | Medium (durability) |

Customized Filtration Solutions

Every industrial process has unique filtration requirements that off-the-shelf solutions may not fully address. This is where customized stainless steel filters become invaluable. Leading wire mesh filter manufacturers excel at providing bespoke designs tailored to specific operational parameters, fluid characteristics, and system interfaces.

Customization options include:

- Material Grade Selection: Beyond standard 304 and 316L, options like 310S, 904L, Duplex, or Super Duplex stainless steel can be specified for extreme corrosion or high-temperature resistance.

- Mesh Count & Weave Pattern: Tailoring the wire diameter, mesh count, and weave style (e.g., plain, twill, Dutch, reverse Dutch) to achieve precise micron ratings and flow characteristics for specific particle sizes and viscosities.

- Filter Element Geometry: Manufacturing custom dimensions, shapes (e.g., specific cone angles, multi-layered cylindrical cartridges, complex disc configurations), and connection types (e.g., threaded, flanged, custom quick-connect) to seamlessly integrate into existing systems.

- Structural Reinforcement: Adding internal or external support structures to withstand high differential pressures, prevent deformation, and extend service life in demanding applications.

- Surface Treatments: Specialized passivation, electropolishing, or coating for enhanced cleanliness, reduced particle adhesion, or improved corrosion resistance in ultra-pure or hygienic processes.

- Multi-Layer & Sintered Construction: Combining multiple layers of mesh with different pore sizes or utilizing sintered metal powder for graded filtration, exceptional strength, and precise absolute filtration ratings.

Engaging with manufacturers early in the design phase allows for collaborative engineering, ensuring that the custom filter solution not only meets performance targets but also optimizes cost-effectiveness and ease of maintenance.

Real-World Application Case Studies

The practical advantages of stainless steel filters are best demonstrated through successful deployments:

Case Study 1: Enhanced Catalyst Recovery in Petrochemical Plant

A major petrochemical company faced challenges with catalyst loss and frequent downtime due to clogging in their polymerization unit's existing filtration system. The high operating temperature (250°C) and corrosive media degraded polymeric filters rapidly. Our team implemented custom-designed, multi-layered 316L stainless steel wire mesh filter cartridges. These filters provided superior heat and corrosion resistance, significantly reducing catalyst loss by 15% and extending filter service life from 3 months to over 18 months, leading to a 40% reduction in maintenance costs and a 5% increase in production uptime. The client praised the exceptional durability and long-term cost savings.

Case Study 2: High-Purity Water Filtration for Pharmaceutical Manufacturing

A leading pharmaceutical firm required an ultra-clean, reusable filtration solution for their purified water system. Existing filters suffered from media migration and could not withstand repeated steam sterilization (SIP) cycles effectively. We engineered electro-polished 304L stainless steel pleated filter cartridges with an absolute micron rating of 0.5 µm. These filters met stringent FDA and USP Class VI requirements, demonstrated excellent performance during SIP cycles, and allowed for repeated backwashing without compromising integrity. The client achieved consistent water purity and a substantial reduction in consumable waste, aligning with their sustainability goals.

Case Study 3: Optimized Hydraulic Oil Filtration in Heavy Machinery

A large-scale mining operation struggled with premature wear of hydraulic components due to inadequate filtration of hydraulic oils, especially under high-pressure conditions and significant particle loads. Disposable filters required frequent changes, impacting operational continuity. We supplied robust sintered 316 stainless steel filter elements, designed for high differential pressure tolerance and excellent dirt-holding capacity. These filters proved exceptionally effective in removing fine particulate contamination, extending the lifespan of hydraulic pumps and valves by over 30%, and drastically reducing filter replacement frequency by 70%. The client reported enhanced equipment reliability and significant savings on spare parts and labor.

Ensuring Trust: Certifications and Authoritative References

Establishing trust in the B2B sector hinges on verifiable credentials and a commitment to quality. Our manufacturing processes and products are underpinned by a robust framework of certifications and adherence to authoritative industry standards:

- ISO 9001:2015 Certified: Our Quality Management System is internationally recognized, ensuring consistent product quality, efficiency, and continuous improvement in all stages from design to delivery.

- Material Certifications: All raw materials, especially stainless steel, are supplied with Mill Test Certificates (MTCs) conforming to ASTM, DIN, and EN standards, guaranteeing material composition and mechanical properties.

- Compliance with Industry Standards: Our stainless steel filters meet or exceed relevant performance and safety standards, including:

- ISO 2941, 2942, 2943: For hydraulic filter elements' collapse/burst resistance, fabrication integrity, and material compatibility.

- ISO 16889: Multi-pass test for evaluating filtration performance (Beta Ratio).

- FDA (21 CFR 177) Compliance: For materials used in food, beverage, and pharmaceutical contact applications, where applicable.

- ANSI/AWWA Standards: For water treatment and potable water applications.

- Partnerships & Client Testimonials: We have successfully served a global clientele, including Fortune 500 companies in petrochemicals, power generation, and food processing, for over two decades. Testimonials and repeat business underscore our reliability and commitment to customer satisfaction.

- Extensive In-house Testing: Our facilities are equipped for comprehensive testing, including pressure differential, flow rate, particle retention efficiency, and metallurgical analysis, ensuring every product batch meets specified performance parameters.

Frequently Asked Questions (FAQ)

Q1: What is the typical service life of a stainless steel filter?

A1: The service life of a stainless steel filter is significantly longer than disposable filters, typically ranging from 5 to 15 years, or even more, depending on the application severity, frequency of cleaning, and material compatibility with the process fluid. Proper maintenance can extend this considerably.

Q2: How do I choose the correct micron rating for my application?

A2: The optimal micron rating depends on the size of the particles you need to remove, the required purity level of the fluid, and potential downstream equipment protection. Our technical team can assist you with this selection based on your specific process data and objectives.

Q3: Are these filters cleanable? If so, how?

A3: Yes, most stainless steel filters are highly cleanable and reusable. Common cleaning methods include backwashing with process fluid or water, ultrasonic cleaning, or chemical cleaning with appropriate solvents. The specific method depends on the contaminant and filter construction.

Q4: Can these filters withstand corrosive chemicals?

A4: Yes, stainless steel is known for its excellent corrosion resistance. For highly aggressive chemicals, we offer filters made from specific grades like 316L, Duplex, or Super Duplex stainless steel, which provide enhanced resistance to chlorides and other potent corrosive agents. Material compatibility should always be verified for critical applications.

Q5: What are the typical lead times for custom stainless steel filters?

A5: Lead times vary based on design complexity, material availability, and order volume. For standard products, lead times are typically 2-4 weeks. For custom-engineered solutions, lead times can range from 4-8 weeks from drawing approval. We work closely with clients to meet project deadlines and offer expedited services where feasible.

Order & Support Information

We are committed to providing exceptional service throughout the entire customer journey, from initial inquiry to long-term operational support.

Lead Time & Fulfillment

Our streamlined manufacturing process and robust supply chain enable competitive lead times. Standard orders typically ship within 2-4 weeks. For custom or high-volume orders, specific timelines will be provided upon consultation and design finalization, ensuring transparent project planning. We offer flexible shipping options to accommodate urgent requirements and global logistics.

Warranty Commitments

All our stainless steel wire mesh filter products come with a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. The standard warranty period is 12 months from the date of installation or 18 months from the date of shipment, whichever comes first. Extended warranty options are available for specific projects.

Customer Support & After-Sales Service

Our dedicated team of filtration experts is available to provide unparalleled support:

- Technical Consultation: Assistance with filter selection, system integration, and optimization.

- Troubleshooting: Expert guidance for resolving operational issues and maximizing filter performance.

- Maintenance & Cleaning Advice: Best practices for extending filter life and maintaining efficiency.

- Spare Parts: Prompt availability of replacement parts and accessories.

- Contact Us: For inquiries, quotes, or support, please visit our website at www.yjwiremesh.com or reach out to our sales and technical support teams.

Conclusion

The demand for reliable, high-performance filtration solutions continues to grow across all industrial sectors. Stainless steel filters represent a cornerstone of this demand, offering an unmatched combination of durability, chemical resistance, high-temperature capability, and reusability. By investing in these advanced filtration systems, businesses can achieve higher operational efficiencies, reduce maintenance costs, ensure product purity, and comply with increasingly stringent environmental regulations.

Partnering with a knowledgeable and experienced manufacturer who can provide both standard and customized solutions, backed by robust quality control and comprehensive after-sales support, is key to leveraging the full potential of stainless steel filtration technology for your specific needs.

References

- ASTM International. (2023). Standards for Stainless Steel. Available at: www.astm.org

- International Organization for Standardization (ISO). (2022). Hydraulic fluid power - Filter elements - Methods of test for verifying performance. Available at: www.iso.org

- Food and Drug Administration (FDA). (2023). Code of Federal Regulations Title 21 - Food and Drugs. Available at: www.fda.gov

- American Water Works Association (AWWA). (2023). Water Treatment Plant Design Standards. Available at: www.awwa.org

- ASM International. (2020). ASM Handbook Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025