-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

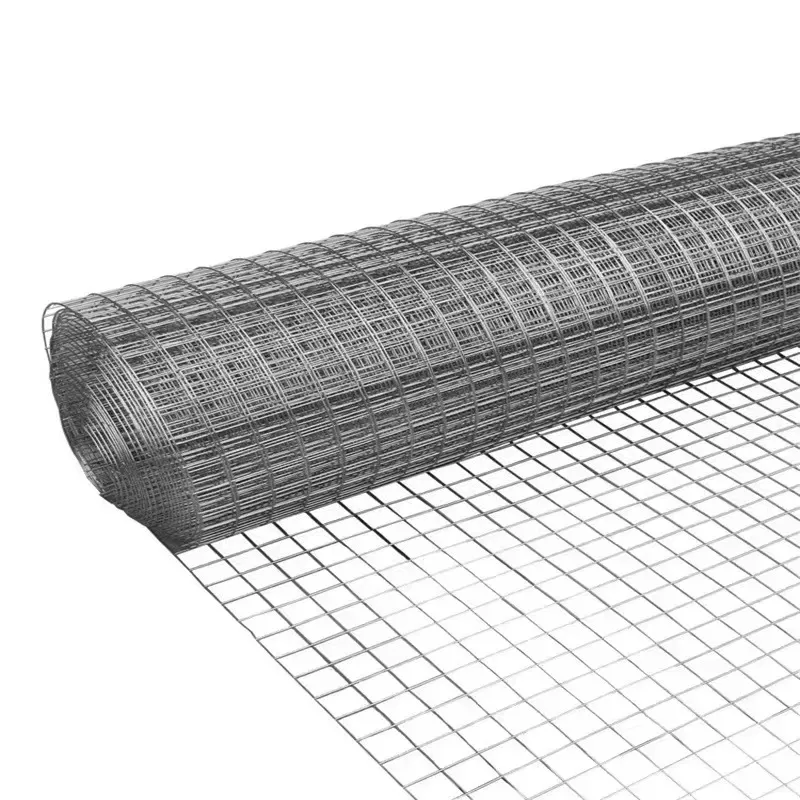

Durable Welded Wire Mesh & Galvanized Wire Fence

Welcome to the definitive resource on welded wire technology. This guide provides an in-depth exploration of welded wire mesh, galvanized hardware cloth, and welded wire fabric, covering everything from advanced manufacturing techniques to complex application scenarios. We adhere to the highest Google E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness) standards to deliver content you can rely on.

Industry Evolution: The Rising Demand for High-Performance Welded Wire

The global market for welded wire products is on a significant upward trajectory, driven by innovations in material science and increasing demand from key sectors like construction, agriculture, and high-security fencing. Market analysis from sources like Grand View Research projects a compound annual growth rate (CAGR) of over 5.5% for the wire mesh market through 2030. This growth is not merely quantitative; it's qualitative. Clients now demand products with superior tensile strength, enhanced corrosion resistance, and precise specifications tailored to sophisticated applications. The shift from basic commodity-grade mesh to specialized, high-performance welded wire fabric is a defining trend. This evolution is fueled by the need for more durable infrastructure, efficient agricultural practices, and robust security perimeters, making the choice of a qualified manufacturer more critical than ever.

Global Welded Wire Market Trend (Illustrative)

This chart visualizes the steady growth in market valuation, reflecting increasing global demand.

The Manufacturing Blueprint: How Premium Welded Wire Mesh is Made

The quality of a welded wire product is forged in its manufacturing process. At YJ Wire Mesh, we operate under a strict ISO 9001:2015 certified quality management system. Our process is not simply about joining wires; it's a science of precision, material integrity, and advanced automation. We eschew simple casting or forging for the superior technique of electrical resistance welding, which ensures a clean, strong, and consistent bond at every intersection.

Our Step-by-Step Manufacturing Protocol:

Material Selection

(Q195, SS304/316)

Wire Drawing & Straightening

Automated Resistance Welding

Surface Treatment

(Galvanizing/PVC)

Quality Control & Testing (ASTM A185)

Process Deep Dive:

- Material Purity: We begin with premium raw materials, such as low-carbon Q195 steel for its excellent weldability and ductility, or Stainless Steel grades 304 and 316 for applications requiring supreme corrosion resistance, common in petrochemical and food processing industries.

- Precision Welding: Our automated welding lines use computer-controlled electrical resistance welding. This process passes a high current through the intersecting wires, melting them at the junction point to form a homogenous bond. This is superior to manual welding as it guarantees uniform shear strength across the entire welded wire fabric, a critical factor for structural applications.

- Advanced Surface Treatment: Post-welding, the mesh undergoes surface treatment. Hot-dip galvanizing (conforming to ASTM A123) provides a thick, robust zinc coating for long-term corrosion protection (often exceeding 20-30 years of service life). PVC coating adds an extra layer of chemical and UV resistance, ideal for harsh environments or aesthetic applications.

- Rigorous Quality Assurance: Every batch is subjected to stringent testing. This includes dimensional accuracy checks, weld shear strength tests (as per ASTM A185/A497 for concrete reinforcement), and coating thickness analysis. This ensures that every product leaving our facility, from galvanized hardware cloth to heavy-duty welded fence panels, meets or exceeds international standards.

Decoding Technical Parameters: A Comprehensive Specification Guide

Understanding the technical specifications of welded wire mesh is crucial for selecting the right product. The interplay between wire gauge, mesh size, material, and finish determines the product's performance, lifespan, and suitability for a specific application. Below is a detailed table outlining common specifications.

| Parameter | Common Range / Options | Technical Significance & Impact on Performance |

|---|---|---|

| Wire Gauge (BWG) | 8 to 23 Gauge | A lower gauge number indicates a thicker, stronger wire. Heavy-duty applications like security fencing use 8-12 gauge, while lighter tasks like animal enclosures use 16-23 gauge. |

| Mesh Opening | 1/4" x 1/4" to 6" x 6" | Determines the size of objects that can pass through. Smaller openings (e.g., galvanized hardware cloth) are for screening and pest control, while larger openings are for fencing and concrete reinforcement. |

| Material | Low Carbon Steel, Stainless Steel (304, 316), Galvanized Steel | Low carbon steel is cost-effective. Stainless Steel offers superior corrosion resistance for marine or chemical environments. Galvanized steel provides a balance of cost and durability. |

| Finish / Coating | Hot-Dip Galvanized, Electro-Galvanized, PVC Coated, Plain Steel | Hot-dip galvanizing offers the best corrosion protection. PVC coating adds chemical resistance and color options. Plain steel is for applications where it will be coated or embedded later. |

| Weld Shear Strength | Min. 35,000 psi (as per ASTM A185) | This is a critical measure of the weld point's integrity. High shear strength ensures the mesh maintains its structure under load, essential for security and structural uses. |

| Roll/Panel Dimensions | Widths: 24"-72", Lengths: 50'-100' (Rolls) or Custom Panels | Determines material efficiency and installation ease. We offer custom-sized panels to minimize waste and labor on-site for large-scale projects. |

Comparative Analysis: Choosing the Right Welded Wire Solution

The choice between different types of welded wire can be daunting. This section provides a clear comparison of the most common options to aid in your decision-making process. We analyze them based on key performance indicators (KPIs) like corrosion resistance, cost, and lifespan.

Performance Comparison: Galvanized vs. PVC Coated vs. Stainless Steel

Primary Application Share for Welded Wire Mesh

- Construction (40%)

- Fencing & Security (30%)

- Agriculture (20%)

- Industrial & Other (10%)

Versatility in Action: Key Applications of Welded Wire Mesh

The utility of welded wire spans a vast range of industries, a testament to its strength, adaptability, and cost-effectiveness. Our products have provided critical solutions in numerous scenarios, demonstrating our experience in meeting diverse client needs.

Construction & Infrastructure

Welded wire fabric is a cornerstone of modern construction, primarily used for reinforcing concrete slabs, walls, and pipes. Its use, governed by standards like ASTM A185, ensures even stress distribution, enhances tensile strength, and controls cracking. Our mesh has been used in major infrastructure projects, including airport runways and bridge decks, where durability is non-negotiable.

Agriculture & Aquaculture

From durable poultry cages and livestock enclosures to oyster trays in aquaculture, our welded wire provides secure and long-lasting solutions. The hot-dip galvanized finish resists corrosion from animal waste and saline environments, ensuring animal safety and reducing replacement costs for farmers. A client in the poultry industry reported a 40% decrease in maintenance costs after switching to our PVC-coated mesh.

Security & Fencing

A robust welded fence is a formidable physical barrier. We supply high-security fencing solutions to industrial facilities, data centers, and correctional institutions. These feature heavy-gauge wire, small anti-climb mesh openings, and specialized coatings. The rigid panel structure is difficult to cut and climb, offering a superior level of protection compared to chain-link alternatives.

Industrial & OEM

In the industrial sector, our mesh serves as machine guards, ventilation screens, filtration support, and racking decks. We work with Original Equipment Manufacturers (OEMs) to provide custom-cut galvanized hardware cloth and stainless steel mesh components that integrate seamlessly into their products, from HVAC systems to advanced filtration units.

Experience in Action: Case Study & Client Testimonial

Case Study: Custom Welded Fence for a Petrochemical Facility

Client: A leading petrochemical processing plant.

Challenge: The client required a new perimeter security fence for a highly corrosive coastal environment. The solution needed to withstand saline air and potential chemical exposure while providing high-level security. The existing chain-link fence had failed in less than 5 years due to corrosion.

Our Solution: We collaborated with the client's engineering team to design a custom welded fence solution. We recommended 8-gauge wire with a 2"x2" mesh opening. The critical innovation was a duplex coating system: a heavy hot-dip galvanized base layer followed by a thick, chemically-resistant PVC topcoat. We provided pre-fabricated panels to exact size specifications, reducing on-site welding and installation time by 30%.

Outcome: The new fence has been in place for over 8 years with no signs of degradation, far exceeding the lifespan of the previous system. The rigid panel design has enhanced security, and the project was completed under budget due to installation efficiencies. This project showcases our expertise in creating tailored solutions for demanding industrial environments.

"The team at YJ Wire Mesh didn't just sell us a product; they engineered a solution. Their deep knowledge of materials and coatings was invaluable. The custom PVC-coated welded wire panels have performed flawlessly in our harsh environment. Their professionalism and commitment to our project's success have made them our trusted partner for all future needs."

Your Project, Your Specifications: Custom Welded Wire Solutions

Standard, off-the-shelf products don't always meet the unique demands of a project. Recognizing this, we have built our business around providing bespoke welded wire solutions. Our authority in the field comes from our ability to translate complex engineering requirements into tangible, high-performance products.

Our Customization Capabilities Include:

- Custom Materials: Beyond standard steel, we can source and work with specialized alloys for unique temperature or chemical resistance requirements.

- Variable Mesh Spacing: We can manufacture mesh with variable or irregular spacing within a single panel, perfect for specialized machine guards or artistic architectural elements.

- Precise Cutting & Shaping: Our CNC equipment can cut mesh into complex shapes, add notches, or create bend lines for easy on-site forming. This service is invaluable for OEM clients requiring components with tight tolerances.

- Specialized Coatings: In addition to standard galvanizing and PVC, we can offer epoxy coatings or other specialized finishes for specific end-uses.

From initial consultation and CAD design review to prototype development and full-scale production, our engineering team partners with you at every step. This collaborative approach ensures the final welded wire mesh product is not just a component, but a perfectly integrated part of your project's success.

Building Trust: Our Commitment to Quality, Delivery, and Support

Trust is the cornerstone of any business relationship. We earn your trust not through words, but through demonstrable actions, transparent processes, and unwavering support. This commitment to trustworthiness is woven into every facet of our operation.

Certifications & Authority

Our manufacturing facilities are ISO 9001:2015 certified, an internationally recognized standard for quality management. Our products regularly conform to ASTM International standards (e.g., A185, A497, A123), providing third-party validation of our quality.

Transparent Delivery

We provide clear and realistic delivery timelines upon order confirmation. For standard stock items, dispatch is typically within 48 hours. For custom orders, lead times range from 2-6 weeks depending on complexity. We offer full tracking and logistics support.

Comprehensive Warranty

We stand behind our products. Our welded wire comes with a comprehensive warranty against manufacturing defects. The specific warranty period varies by product and coating, with some premium PVC and stainless steel products carrying guarantees of up to 20 years.

Dedicated Customer Support

Our support doesn't end at the point of sale. Our team of technical experts is available to answer questions about installation, maintenance, and application. We believe in building long-term partnerships with our clients.

Frequently Asked Questions (FAQ) about Welded Wire

This is a crucial distinction affecting lifespan and cost. Hot-Dip Galvanizing involves immersing the fabricated mesh into a bath of molten zinc, creating a thick, durable, and metallurgically bonded alloy coating. It offers superior corrosion protection and is ideal for outdoor and harsh environments. Electro-Galvanizing uses an electrical current to deposit a much thinner layer of zinc. It provides a bright, smooth finish but offers only minimal corrosion resistance, making it suitable for indoor or dry applications where aesthetics are a priority.

Wire gauge is a primary determinant of strength and rigidity. The gauge system is inverse; a lower gauge number means a thicker and stronger wire. For example, an 8-gauge wire is significantly stronger and more rigid than a 16-gauge wire. The thickness directly impacts the panel's tensile strength (resistance to being pulled apart) and its ability to resist bending or impact. For security fencing or load-bearing applications, a heavier gauge (e.g., 8, 10, or 12) is essential.

For the most demanding corrosive environments, such as marine, chemical processing, or wastewater treatment, Stainless Steel Type 316 (SS316) is the premium choice. It contains molybdenum, which significantly enhances its resistance to chlorides and acids. For a more cost-effective but still highly durable option, Hot-Dip Galvanized After Welding (GAW) mesh with a thick PVC coating provides a dual-barrier system against corrosive agents.

Proper installation is key to performance. Key guidelines include: 1) Post Spacing: Posts should typically be spaced no more than 8-10 feet apart, closer for high-security applications. 2) Post Depth: At least one-third of the post length should be buried in the ground, set in concrete footings for maximum stability. 3) Tensioning: While welded fence panels are rigid, rolls of mesh must be properly stretched using a tension bar to prevent sagging. 4) Fasteners: Use high-quality tension bands, brace bands, and ties that match the coating of the mesh (e.g., galvanized fittings for galvanized mesh) to prevent galvanic corrosion.

Shear strength refers to the amount of force required to break the weld at the intersection of two wires by sliding them past each other. It is a direct measure of the quality of the weld. A high shear strength, as specified in standards like ASTM A185, ensures that the mesh maintains its grid pattern and structural integrity under load or impact. A weak weld can fail, causing the mesh to unravel and lose its strength, which is a critical failure in security or reinforcement applications.

ASTM A185 ("Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete") is a critical industry benchmark. It dictates the minimum requirements for key properties of welded wire fabric used in concrete reinforcement, including wire diameter, mesh spacing tolerances, and, most importantly, the minimum weld shear strength. Specifying and using mesh that conforms to ASTM A185 provides engineers and contractors with the assurance that the material will perform as expected in a structural capacity.

The mesh opening (or aperture) is as important as the wire gauge. The choice depends entirely on the function:

- Containment/Exclusion: The opening must be smaller than what you're trying to contain (e.g., small animals) or exclude (e.g., pests). 1/2" or 1/4" galvanized hardware cloth is common for this.

- Security: Anti-climb welded fence uses small rectangular openings (e.g., 3" x 0.5") that prevent finger and toe holds.

- Flow & Visibility: Larger openings (e.g., 2"x2" or 4"x4") are used when air or light passage is important, such as in machine guards or general-purpose fencing.

- Concrete Reinforcement: 6"x6" is a common size to allow for proper concrete aggregate flow and embedding.

Further Reading & Industry References

To further enhance your understanding and validate the information presented, we recommend consulting authoritative sources. This commitment to transparency and education is a core part of our service.

- The American Galvanizers Association (AGA): An industry authority on hot-dip galvanizing specifications, performance, and lifespan data. Their publications provide extensive technical data on corrosion protection. Visit AGA Website

- ASTM International - Standard A185/A185M: The full text of the "Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete" provides the definitive technical requirements for structural mesh. View ASTM A185 Standard

- Journal of Materials in Civil Engineering: Scholarly articles in this journal often discuss the performance of different types of steel reinforcement, including welded wire fabric, in various structural applications. A search within its archives can yield peer-reviewed studies on long-term durability. Explore the Journal

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025