-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

electro welded mesh

The Significance of Electro Welded Mesh in Modern Construction

Electro welded mesh, commonly referred to as welded wire mesh, has become an essential component in various construction applications. This innovative material is manufactured by welding together intersecting steel wires at each point, creating a robust and durable mesh structure. Its increasing popularity in construction and engineering industries can be attributed to a myriad of advantages and versatile uses.

One of the primary benefits of electro welded mesh is its exceptional strength and stability. The welding process ensures that each wire is securely bonded, which contributes to the overall integrity of the mesh. This makes it an ideal choice for reinforcing concrete slabs, walls, and floors. By incorporating electro welded mesh into construction projects, engineers can significantly enhance the load-bearing capacity and longevity of structures.

Additionally, the consistency in quality and size of electro welded mesh makes it a reliable material for construction. Unlike traditional methods that may involve variable quality due to manual labor, the electro welding process is automated and controlled, ensuring uniformity throughout. This high level of consistency not only improves the aesthetics of concrete applications but also simplifies planning and implementation.

electro welded mesh

The versatility of electro welded mesh extends beyond merely reinforcement

. It is used in a variety of applications, including fencing, security barriers, and even in agricultural settings. For instance, in agricultural fencing, it provides a strong yet flexible solution to contain livestock and protect crops. Its adaptability is further demonstrated in architectural applications, where it can be utilized as an attractive design element in facades and interior spaces.Moreover, electro welded mesh is also praised for its cost-effectiveness. While the initial investment may appear significant, its durability and reduced maintenance costs lead to long-term savings. Structures incorporating welded mesh are less likely to suffer from structural failures, which can often incur hefty repair bills.

Another notable advantage of electro welded mesh is its eco-friendliness. As a steel product, it can be recycled at the end of its life cycle. This sustainability feature resonates well with the ongoing movement in the construction industry towards greener building practices.

In conclusion, electro welded mesh stands at the forefront of modern construction materials with its strength, versatility, and cost-effectiveness. Its application goes beyond simple reinforcement, playing a critical role in various sectors including agriculture and architecture. As the industry continues to evolve, the importance and use of electro welded mesh are likely to expand, solidifying its position as a fundamental component in building resilient structures for the future.

-

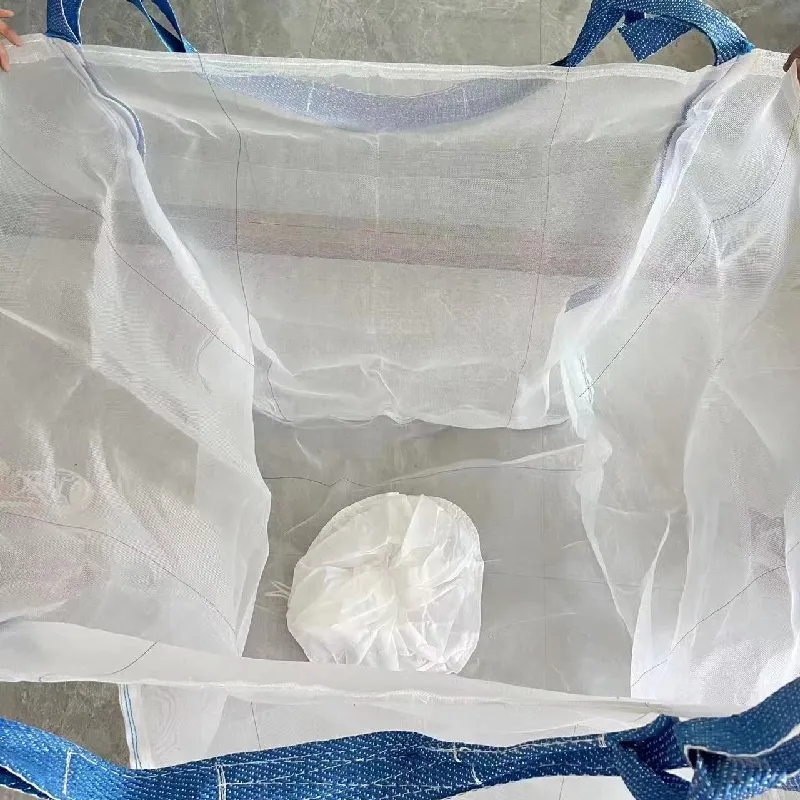

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025