-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

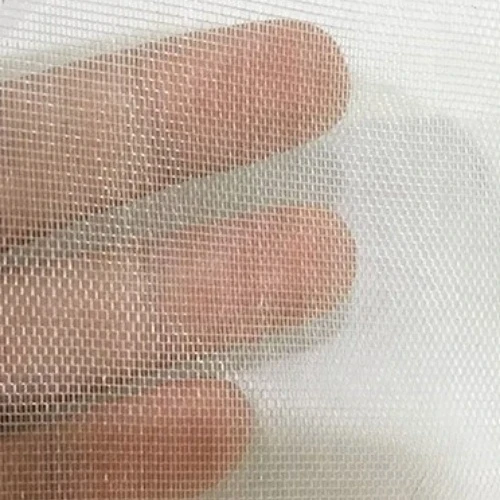

electro welded mesh

Understanding Electro Welded Mesh Applications and Benefits

Electro welded mesh, often referred to as welded wire mesh or simply welded mesh, is a type of steel wire mesh made by welding wires together at intersections using electricity. This innovative manufacturing process offers a robust and versatile solution for a variety of applications ranging from construction to safety and agriculture.

What is Electro Welded Mesh?

Electro welded mesh consists of multiple strands of wire that are laid out in a grid pattern. The wires are welded at their intersections using a process known as electro fusion, which involves the application of high electrical current to melt the wire ends together. The result is a strong, durable mesh product that maintains its shape and integrity, providing an effective barrier or support system.

This type of mesh can be manufactured in various sizes and configurations, with wire diameters typically ranging from 1.5mm to 12mm, and mesh spacing commonly varying from 25mm to 200mm. The versatility in production allows for both standard and customized mesh, making it suitable for a broad array of industrial and commercial needs.

Applications of Electro Welded Mesh

1. Construction and Building Industry One of the primary applications of electro welded mesh is in the construction sector. It is extensively used in reinforced concrete structures, such as floors, slabs, and walls, providing strength and flexibility. The mesh helps to distribute loads evenly, reducing the risk of cracking and enhancing the longevity of concrete components.

2. Fencing and Security Electro welded mesh is also commonly used for fencing solutions. Its robust nature makes it ideal for high-security applications, including prisons, military installations, and high-value storage areas. The mesh can be designed to various heights and strengths, ensuring that it provides an effective deterrent against unwanted access.

3. Agriculture In agriculture, electro welded mesh serves many functions, such as animal enclosures, crop protection, and greenhouse structures. The visibility through the mesh allows for adequate sunlight penetration while still providing a protective barrier against pests and larger animals.

4. Manufacturing and Industrial Applications Various industries utilize electro welded mesh for storage racks, shelving systems, and equipment guarding. Its strength and flexibility allow manufacturers to create customized solutions that adhere to safety regulations while maximizing space utilization.

electro welded mesh

5. Home Improvement and DIY Projects For home improvement enthusiasts, electro welded mesh can be used in various DIY projects, such as creating garden trellises, decorative gates, or even protective barriers around pools. Its ease of handling and installation makes it an attractive option for homeowners looking to enhance their outdoor spaces.

Benefits of Electro Welded Mesh

The benefits of using electro welded mesh extend beyond its structural integrity. Here are some key advantages

- Strength and Durability The welding process creates a solid bond between wire intersections, resulting in a mesh that can withstand high loads and resist deformation over time.

- Cost-Effectiveness Compared to other forms of fencing and reinforcement solutions, electro welded mesh often proves to be a more economical option, providing long-lasting performance with minimal maintenance.

- Versatility The wide range of sizes and configurations available allows for customization to meet specific needs, making it suitable for diverse applications across various industries.

- Ease of Installation Electro welded mesh is relatively easy to handle and install, saving time and labor costs in both commercial and residential applications.

- Aesthetic Appeal With the option to select various finishes and coatings, electro welded mesh can provide an aesthetically pleasing look while still offering functionality.

In conclusion, electro welded mesh is a highly functional and versatile solution that caters to various sectors, enhancing strength, security, and efficiency. Understanding its potential applications and benefits can help individuals and businesses make informed decisions when considering it for construction, fencing, or agricultural needs. As industries continue to evolve, the demand for durable and reliable materials like electro welded mesh is likely to grow, further solidifying its role as a key component in modern construction and manufacturing practices.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025