-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 05, 2025 01:34

Back to list

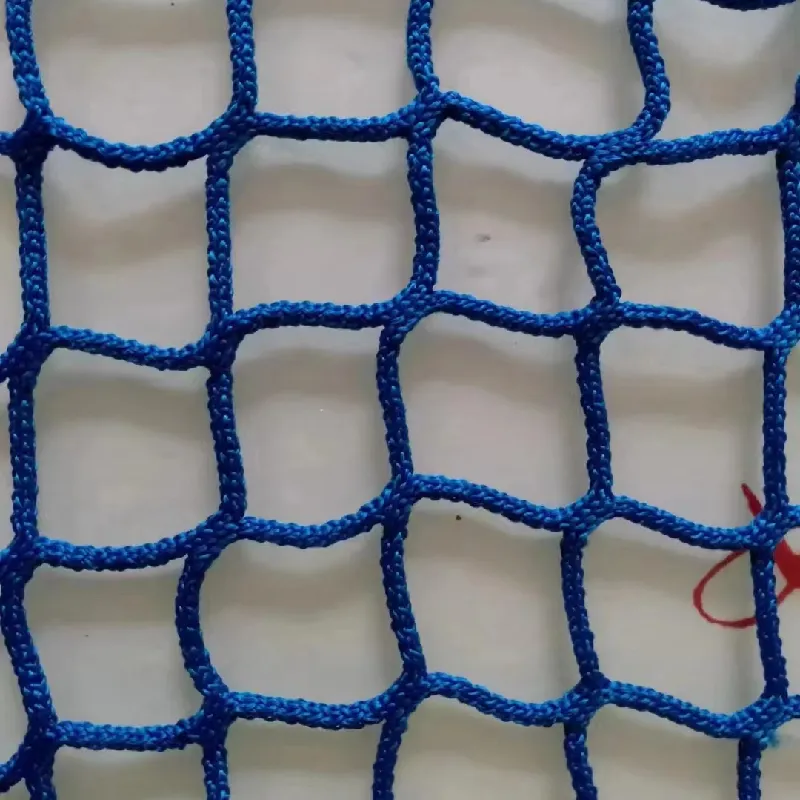

electro welded mesh

Electro welded mesh stands as a pivotal product in the realms of construction and industrial applications, known for its robustness, versatility, and efficiency. This type of mesh, defined by its electrically welded intersections, serves a multitude of purposes, from reinforcing concrete structures to providing security in fencing solutions. Understanding its critical attributes and applications can significantly enhance your selection process, ensuring that the mesh chosen aligns perfectly with your project requirements.

Experienced professionals advocate for the use of electro welded mesh due to its ease of installation. The uniform grid layout reduces the need for additional labor to position and secure the mesh, which often translates to cost savings in large projects. Additionally, its robust nature means it can withstand transportation and handling without deforming, further enhancing its practicality on-site. Moreover, the environmental footprint of using electro welded mesh is minimal in comparison to more traditional reinforcement methods. The precision in its production process leads to less waste, and its longevity ensures that structures reinforced with this mesh need less frequent repairs or replacements. With sustainability becoming a key consideration in modern construction, the low environmental impact of electro welded mesh is a significant advantage. In conclusion, electro welded mesh exemplifies a product that combines strength, versatility, and reliability, making it a cornerstone in construction and industrial use. Its ability to meet international standards reinforces its authority and trustworthiness in the marketplace. For those seeking an efficient, cost-effective solution to reinforcement needs, electro welded mesh promises to deliver exceptional results, backed by professional expertise and years of proven performance in the field. Whether you're constructing a massive infrastructure project or a small-scale residential building, integrating electro welded mesh into the framework can significantly enhance the overall quality and durability of your work.

Experienced professionals advocate for the use of electro welded mesh due to its ease of installation. The uniform grid layout reduces the need for additional labor to position and secure the mesh, which often translates to cost savings in large projects. Additionally, its robust nature means it can withstand transportation and handling without deforming, further enhancing its practicality on-site. Moreover, the environmental footprint of using electro welded mesh is minimal in comparison to more traditional reinforcement methods. The precision in its production process leads to less waste, and its longevity ensures that structures reinforced with this mesh need less frequent repairs or replacements. With sustainability becoming a key consideration in modern construction, the low environmental impact of electro welded mesh is a significant advantage. In conclusion, electro welded mesh exemplifies a product that combines strength, versatility, and reliability, making it a cornerstone in construction and industrial use. Its ability to meet international standards reinforces its authority and trustworthiness in the marketplace. For those seeking an efficient, cost-effective solution to reinforcement needs, electro welded mesh promises to deliver exceptional results, backed by professional expertise and years of proven performance in the field. Whether you're constructing a massive infrastructure project or a small-scale residential building, integrating electro welded mesh into the framework can significantly enhance the overall quality and durability of your work.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025