-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Future of Mining Mesh Technologies and Their Applications

The Role of Mining Mesh in Modern Extraction Techniques

In the rapidly evolving world of mining, efficiency and safety are paramount. Among the innovations that have emerged to address these concerns is the use of mining mesh. This material, integral to various mining operations, has transformed how miners approach stability and extraction processes.

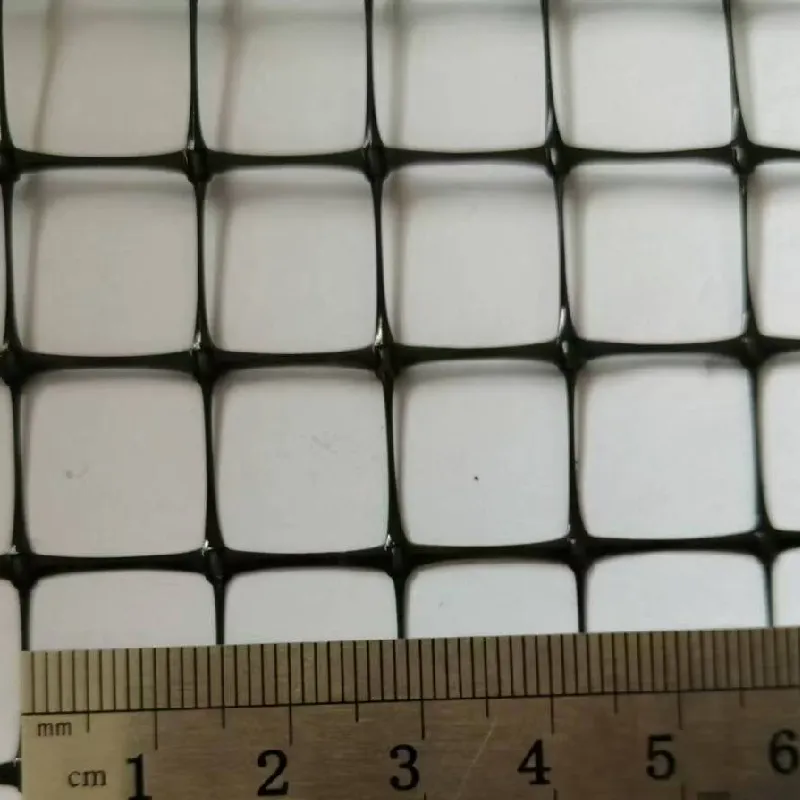

Mining mesh, typically composed of durable materials like steel or high-strength polymers, serves multiple functions in diverse mining environments. It is primarily designed to reinforce ground support, ensuring that tunnels and shafts remain stable during excavation. The application of mining mesh helps to mitigate the risks of collapses, particularly in underground operations where the integrity of the rock formations is critical.

One of the most significant advantages of mining mesh is its ability to enhance safety. By providing a sturdy barrier, it prevents loose rock and debris from falling into work areas, thereby protecting miners and equipment from potential hazards. This improvement in safety standards not only helps in reducing accidents but also minimizes downtime, allowing for more efficient extraction processes.

In addition to safety, mining mesh contributes to environmental sustainability

. The mining industry has faced increasing scrutiny over its environmental impact, and implementing technologies that reduce this footprint is essential. The use of mining mesh aids in controlling dust and debris, which can have detrimental effects on air quality. By keeping the site cleaner and more organized, mining companies can adhere to environmental regulations and promote responsible mining practices.mining mesh

The versatility of mining mesh is another aspect that makes it so valuable. It can be tailored to suit various mining operations, whether in coal, metal, or stone mining. Different mesh designs and materials can be employed based on specific requirements and conditions of the mining site. This adaptability means that miners can optimize their resource extraction methods while ensuring safety and stability.

Moreover, the installation of mining mesh can be completed relatively quickly compared to traditional support methods, which often involve heavy machinery and extensive labor. This efficiency introduces significant cost savings, allowing mining operations to allocate resources more effectively. In a competitive industry, these savings can have a substantial impact on a company’s bottom line.

As technology continues to advance, the future of mining mesh looks promising. Innovations in materials science are leading to the development of even lighter and stronger alternatives, enhancing the effectiveness of mining mesh systems. Smart materials that can adapt to environmental changes and monitor conditions in real time are on the horizon, promising to revolutionize how mesh systems are utilized in the mining industry.

Furthermore, the integration of drones and automation in mining operations has changed how mining mesh is deployed. Drones can now be used to assess the condition of tunnels and shafts, enabling miners to identify areas where mesh may be needed even before excavation begins. This proactive approach can prevent potential hazards and improve planning and execution.

In conclusion, mining mesh is a crucial component of modern mining practices, improving safety, efficiency, and environmental sustainability. Its adaptability and ease of installation have made it a preferred choice in various mining types, and ongoing advancements promise to further enhance its effectiveness. As the industry continues to evolve, mining mesh will undoubtedly play a vital role in shaping the future of resource extraction. By prioritizing safety and efficiency, mining mesh positions the industry for success in an increasingly complex global landscape.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025