-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Versatile Applications and Benefits of Industrial Mesh in Various Industries Today

Understanding Industrial Mesh Applications, Types, and Benefits

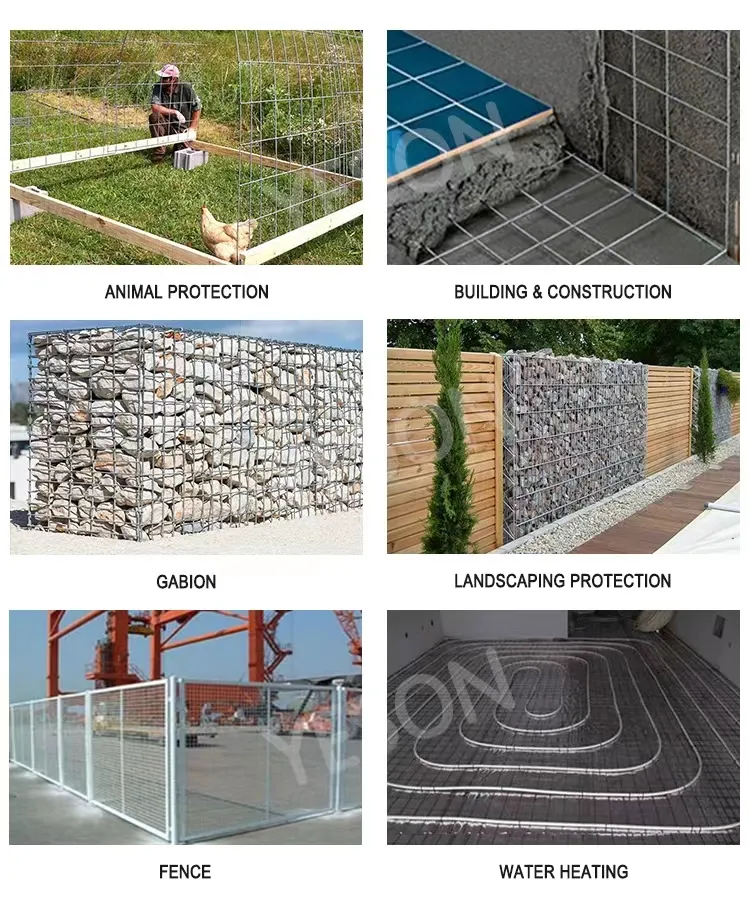

Industrial mesh refers to the finely woven or engineered materials that play a crucial role in a variety of industries. From construction to manufacturing, the use of industrial mesh has grown significantly due to its versatility, strength, and functionality. This article will explore the various applications, types, and benefits of industrial mesh, highlighting why it is an integral component in numerous processes.

Applications of Industrial Mesh

Industrial mesh serves a range of applications across multiple sectors. In construction, it is commonly used for reinforcing concrete structures, providing stability and improving tensile strength. In the manufacturing sector, metal mesh can be found in filtration systems, where it traps contaminants and ensures the purity of liquids and gases. The food and beverage industry often utilizes mesh in processing equipment to separate solids from liquids, ensuring product quality and safety.

Another area where industrial mesh is widely employed is in the agriculture sector. Mesh materials are used to create protective barriers for crops, helping to guard against pests and harsh weather conditions. In aquaculture, mesh is used in fish farming to provide protection and support for aquatic life. Additionally, industrial mesh finds its place in the automotive industry, where it is used in bumpers, grilles, and other components to enhance durability and safety.

Types of Industrial Mesh

There are several types of industrial mesh, each tailored for specific uses and requirements

. Wire mesh, made from stainless steel or other durable metals, is known for its strength and resistance to corrosion. It is commonly used in filtration systems, architectural applications, and safety screens.Another type is synthetic mesh, typically made from polymers like polyethylene or polypropylene. This kind of mesh is often used in agricultural applications, such as crop covers or erosion control, due to its lightweight nature and excellent flexibility.

industrial mesh

Expanded metal mesh is another popular option, produced by cutting and stretching a sheet of metal to create a network of openings. Its ability to allow light and air to pass through while maintaining structural integrity makes it ideal for uses in fencing and safety barriers.

Benefits of Industrial Mesh

The use of industrial mesh comes with numerous benefits. One of the key advantages is its strength and durability. Mesh products can withstand high levels of stress and are designed to function effectively in harsh environments. This makes them reliable components in critical applications where safety is paramount.

Another benefit is versatility. Industrial mesh can be tailored to fit specific needs by varying the material, size, and pattern of the mesh. This adaptability allows industries to find a suitable solution for almost any requirement.

Easy maintenance is also a notable advantage of industrial mesh. Its design minimizes the buildup of debris and contaminants, making it easier to clean and maintain. This is particularly important in industries like food processing, where hygiene is essential.

Furthermore, industrial mesh can contribute to cost savings. By using it as a reinforcing or protective measure, industries can enhance the longevity of their products and reduce the need for frequent replacements. This efficiency can lead to significant long-term savings.

Conclusion

In summary, industrial mesh is a versatile and critical component in various industries, offering significant benefits such as strength, durability, and adaptability. With applications ranging from construction and agriculture to manufacturing and automotive, the demand for industrial mesh continues to grow. As industries evolve, the development of new types of mesh will likely enhance their functionality and expand their uses, solidifying their place as an indispensable material in modern manufacturing and production processes.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025