-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

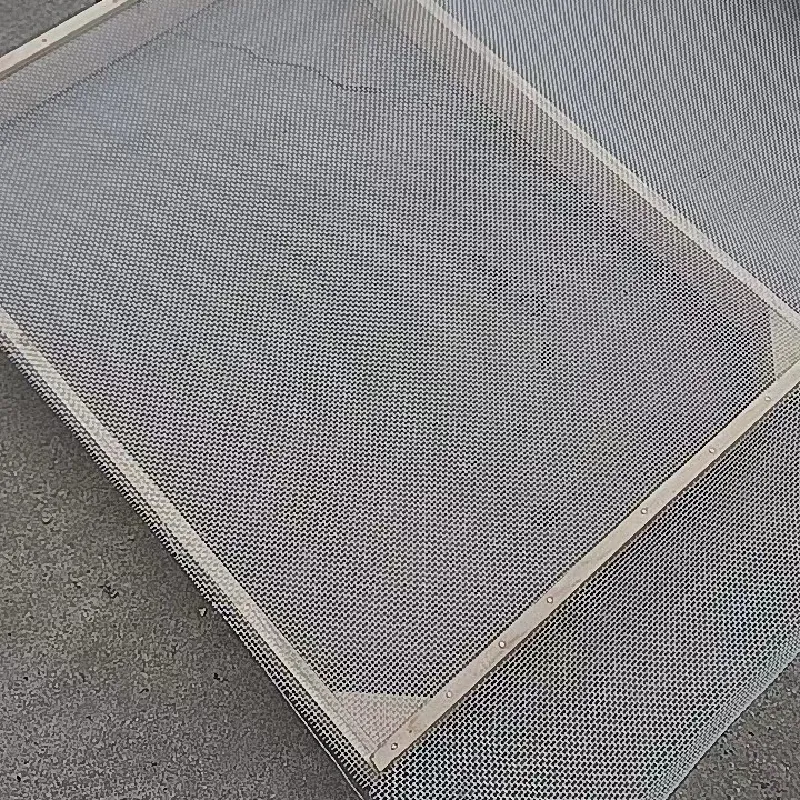

filter mesh stainless steel

Understanding Stainless Steel Filter Mesh A Versatile Solution for Various Applications

Stainless steel filter mesh has become an essential component in various industries due to its outstanding properties and performance. Known for its durability, resistance to corrosion, and high strength, stainless steel mesh is often utilized in applications where filtration, separation, or screening is required. This article explores the characteristics and benefits of stainless steel filter mesh, shedding light on its widespread use in different sectors.

Understanding Stainless Steel Filter Mesh A Versatile Solution for Various Applications

Stainless steel filter mesh is manufactured in various grades, with common options including 304 and 316 stainless steel. Grade 304, often referred to as the 18/8 stainless steel, is widely used for its good corrosion resistance and formability. Grade 316, which contains molybdenum, offers improved resistance to pitting and crevice corrosion, making it suitable for marine applications and environments with high levels of chlorides. The choice between grades depends on the specific requirements of the application, ensuring optimal performance and longevity.

filter mesh stainless steel

The versatility of stainless steel filter mesh extends beyond its material properties. It is available in various mesh sizes, wire diameters, and woven patterns, which can be tailored to meet specific filtration needs. Fine mesh is typically used for applications requiring high precision, such as laboratory filtration and pharmaceutical production, whereas coarser mesh is utilized in more robust applications like mining and aggregate processing.

In addition to its filtration capabilities, stainless steel filter mesh can be employed in diverse applications such as strainers, sieves, and guards. Its strength and structural integrity allow it to withstand significant mechanical stresses, making it suitable for use in demanding environments.

Finally, the ease of cleaning and maintenance further enhances the appeal of stainless steel filter mesh. Unlike porous materials, which can trap contaminants, stainless steel can be efficiently cleaned and sanitized, ensuring consistent performance and hygiene in applications like food processing.

In conclusion, stainless steel filter mesh is a vital component in numerous industries due to its corrosion resistance, durability, and versatility. Whether for filtration, separation, or structural applications, the choice of stainless steel filter mesh guarantees not only efficiency but also safety and reliability, confirming its status as a preferred material in modern manufacturing and processing.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025