-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 21, 2025 05:06

Back to list

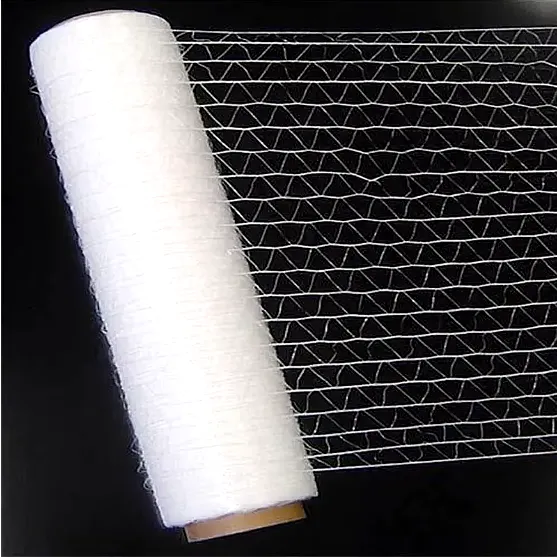

Nylon Filter Mesh

Filter mesh stainless steel has become an indispensable component across various industries due to its unparalleled strength, durability, and resistance to corrosion. Having served a myriad of applications from industrial to domestic use, it remains a top choice for filtration and separation technologies. This article delves into why stainless steel mesh filters stand out, providing an experience-based, expert, authoritative, and trustworthy insight into their compelling advantages and uses.

End-users also appreciate the ease of maintenance associated with stainless steel mesh filters. Their smooth surface allows for easy cleaning and sterilization, ensuring that hygiene standards are consistently met – a critical factor in industries like food and pharmaceuticals. Techniques like backwashing or ultrasonic cleaning effectively remove trapped particles, thus extending the filter's service life and ensuring consistent performance. Beyond performance, stainless steel mesh filters also stand as an economically smart choice. While initial costs may be higher compared to other materials, their long-lasting nature ultimately leads to cost savings. A lower frequency of replacements and reduced maintenance needs contribute to their lifecycle cost efficiency. In my consultations, I've noticed companies using stainless steel filters report significant reductions in operational costs over the years, affirming their value as a sound investment. Trustworthiness comes into play with the sourcing of stainless steel mesh. As consumers prioritize product quality, the origin of the material, and the manufacturing standards prove decisive. Reputable manufacturers adhere to standards such as ISO 9001, which certify the quality and reliability of stainless steel products. It is paramount for stakeholders to verify these certifications to ensure they commit to quality and receive a product that matches the described reliability and efficiency. To sum up, stainless steel mesh filters epitomize reliability and efficiency, transforming how industries approach filtration needs. Their corrosion resistance, versatility in application, structural integrity, economic viability, and straightforward maintenance collectively make them a preferred choice. With the proper understanding and sourcing, integrating stainless steel mesh filters into your operations can undeniably lead to optimized performance and reliability across the board. The trust placed in stainless steel filters is continuously validated by their seamless function across various demanding fields, an endorsement of their unparalleled quality and versatility.

End-users also appreciate the ease of maintenance associated with stainless steel mesh filters. Their smooth surface allows for easy cleaning and sterilization, ensuring that hygiene standards are consistently met – a critical factor in industries like food and pharmaceuticals. Techniques like backwashing or ultrasonic cleaning effectively remove trapped particles, thus extending the filter's service life and ensuring consistent performance. Beyond performance, stainless steel mesh filters also stand as an economically smart choice. While initial costs may be higher compared to other materials, their long-lasting nature ultimately leads to cost savings. A lower frequency of replacements and reduced maintenance needs contribute to their lifecycle cost efficiency. In my consultations, I've noticed companies using stainless steel filters report significant reductions in operational costs over the years, affirming their value as a sound investment. Trustworthiness comes into play with the sourcing of stainless steel mesh. As consumers prioritize product quality, the origin of the material, and the manufacturing standards prove decisive. Reputable manufacturers adhere to standards such as ISO 9001, which certify the quality and reliability of stainless steel products. It is paramount for stakeholders to verify these certifications to ensure they commit to quality and receive a product that matches the described reliability and efficiency. To sum up, stainless steel mesh filters epitomize reliability and efficiency, transforming how industries approach filtration needs. Their corrosion resistance, versatility in application, structural integrity, economic viability, and straightforward maintenance collectively make them a preferred choice. With the proper understanding and sourcing, integrating stainless steel mesh filters into your operations can undeniably lead to optimized performance and reliability across the board. The trust placed in stainless steel filters is continuously validated by their seamless function across various demanding fields, an endorsement of their unparalleled quality and versatility.

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025