-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring Various Types of Filter Steel and Their Applications in Industry

The Importance of Filter Steel in Modern Applications

In the ever-evolving landscape of industrial materials, filter steel has emerged as a critical component in various applications, particularly in the fields of construction, manufacturing, and environmental engineering. This specialized steel possesses unique properties that make it ideal for use in filters, where strength, durability, and resistance to corrosion are paramount.

Understanding Filter Steel

Filter steel is a type of steel specifically designed for use in filtration systems. These systems can be found in a diverse range of industries, including water treatment, chemical processing, and food production. The primary function of filter steel is to effectively separate impurities from liquids and gases. Unlike standard steel, filter steel undergoes specific treatments to enhance its physical and chemical properties, ensuring optimal performance in challenging environments.

One of the most critical characteristics of filter steel is its porous nature. The steel is crafted to create a network of fine holes, allowing for the passage of liquids while trapping solid particles. This feature is essential in applications such as wastewater treatment, where filter steel screens are utilized to remove contaminants before the water is released back into the environment. The effectiveness of these filters plays a vital role in safeguarding public health and preserving ecosystems.

Applications of Filter Steel

The applications of filter steel span across several industries. In water treatment facilities, filter steel is employed to purify potable water, ensuring it meets health standards. Given the increasing global demand for clean water, the role of filter steel in this process cannot be overstated. It serves as a key barrier against sediments, algae, and harmful microorganisms, facilitating cleaner and safer water supplies.

In the chemical processing industry, filter steel is used in various filters and separators designed to handle corrosive substances. The durability and resistance to chemical reactions make filter steel an ideal choice for securing the integrity of filtration systems that process acids, solvents, and other reactive materials. The longevity of filter steel components contributes to lower maintenance costs and reduced downtime, offering significant economic advantages.

filter steel

The food industry also benefits greatly from the use of filter steel. In processes involving the filtration of liquids, such as juices and oils, filter steel ensures that the final products are free of contaminants. This not only enhances the quality of the products but also complies with stringent health regulations. The ability of filter steel to withstand high temperatures and pressures further solidifies its position as a preferred material in food and beverage manufacturing.

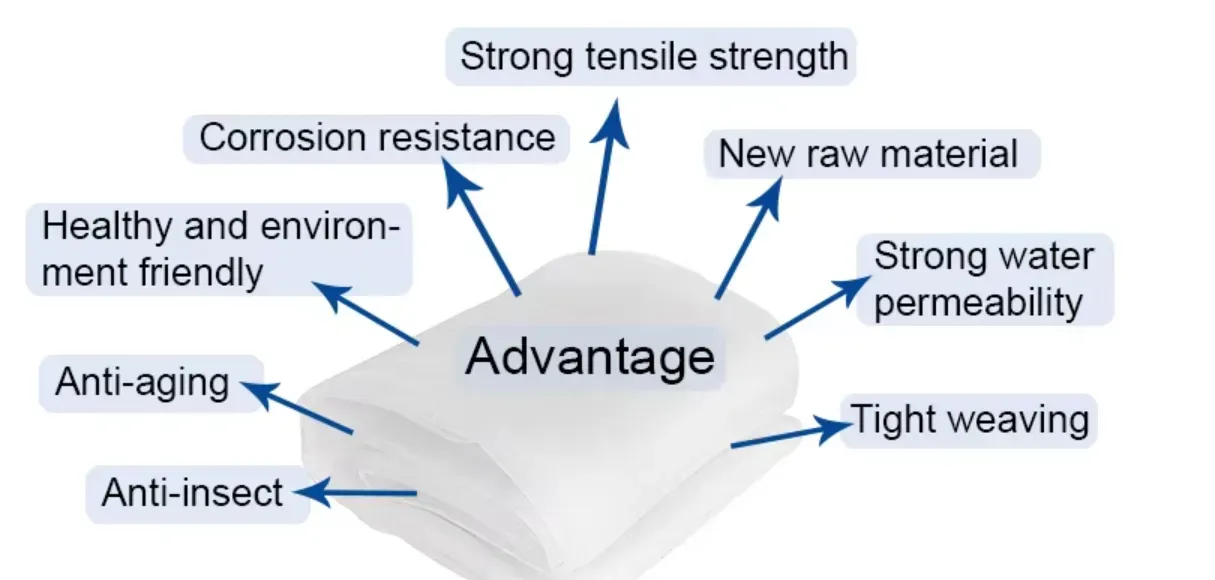

Advantages of Filter Steel

Filter steel offers numerous advantages over traditional filtering materials. First and foremost, it provides exceptional strength and durability. Unlike plastic or cloth filters that may degrade over time, filter steel can withstand harsh conditions without compromising performance. Its resistance to corrosion and wear extends its lifespan, making it a cost-effective investment for industries that rely heavily on filtration.

Moreover, filter steel is easier to clean and maintain. The ability to remove residues without damaging the material ensures consistent performance over time. This is particularly important in industries like pharmaceuticals, where cleanliness and hygiene are non-negotiable.

Sustainability and the Future of Filter Steel

As industries worldwide move towards more sustainable practices, filter steel is well-positioned to lead the charge. Its recyclability and longevity make it an environmentally friendly option compared to single-use plastic filters. Furthermore, innovations in production techniques are paving the way for more efficient manufacturing processes, reducing waste and energy consumption.

In conclusion, filter steel is more than just a material; it is a cornerstone of modern filtration solutions across various industries. With its unique properties, filter steel enhances efficiency, ensures safety, and contributes to environmental sustainability. As we continue to seek solutions to global challenges, the role of high-performance materials like filter steel will undoubtedly expand, shaping the future of filtration technology. Industry leaders must recognize and harness the potential of filter steel to drive innovation and meet the growing demands of a cleaner, safer world.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025