-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

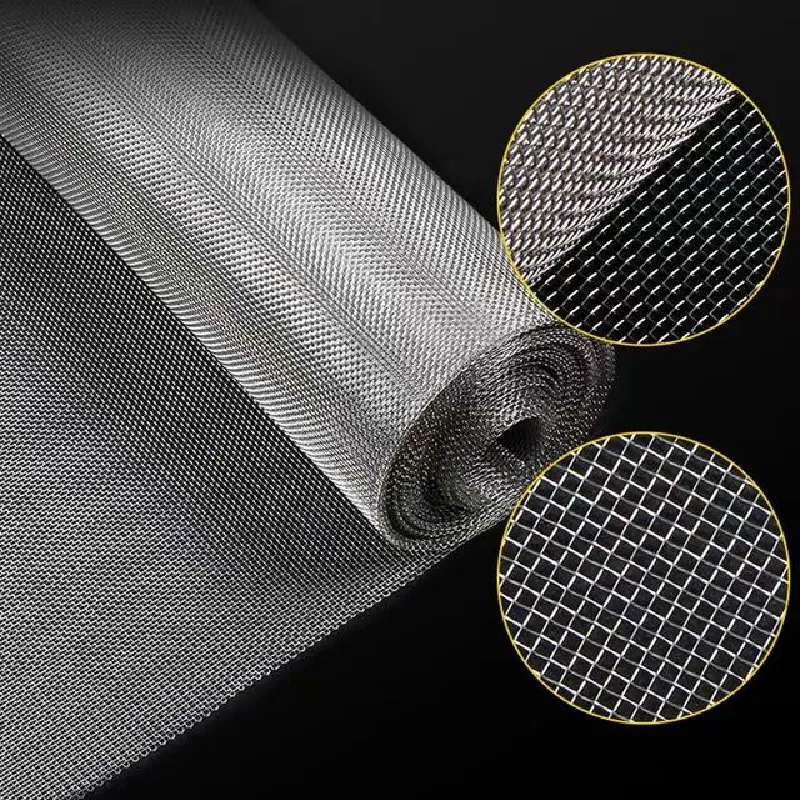

filter steel mesh

Exploring Filter Steel Mesh A Versatile Solution for Filtration Needs

In today's fast-paced industrial landscape, efficiency and precision are paramount. One of the unsung heroes in achieving these goals is the filter steel mesh. This versatile material plays a crucial role in various applications, from water treatment to food processing and beyond. In this article, we will delve into the properties, applications, and benefits of filter steel mesh, highlighting its significance in modern filtration systems.

What is Filter Steel Mesh?

Filter steel mesh is typically made from stainless steel or carbon steel, and it is designed to allow fluids or gases to pass through while trapping unwanted particles and contaminants. The mesh is woven or welded into a grid pattern, with varying pore sizes depending on the intended filtration purpose. This adaptability makes filter steel mesh an essential component in numerous industries by ensuring that processes remain efficient and products maintain quality.

Key Properties

1. Durability Steel is inherently strong, offering robust resistance to wear and tear. Filter steel mesh can withstand high pressures and temperatures, making it suitable for demanding environments. 2. Corrosion Resistance Stainless steel variants of filter mesh provide excellent resistance to rust and corrosion, ensuring longevity and reliability even in harsh conditions.

3. Easy Maintenance Cleaning filter steel mesh is relatively straightforward. Many applications allow for simple backwashing or rinsing, ensuring that the mesh can be reused without significant degradation in performance.

4. Customizability Filter steel mesh can be fabricated in various sizes, shapes, and mesh densities to cater to specific needs. This versatility allows for tailored solutions that meet unique industrial requirements.

Applications of Filter Steel Mesh

filter steel mesh

1. Water Treatment In the water purification process, filter steel mesh is employed to remove large particles and sediments. It serves as a pre-filter in many systems, prolonging the life of finer filters.

2. Food and Beverage Processing Filter steel mesh is widely used in the food industry to ensure the cleanliness and safety of products. It is often used to filter oils, juices, and other liquids, ensuring that undesirable particles are removed, which protects both equipment and consumers.

3. Chemical Industry The chemical sector utilizes filter steel mesh to separate solids from liquids. It plays a vital role in processes such as filtration of catalysts, slurries, and other chemical mixtures, ensuring purity and effectiveness.

4. Pharmaceuticals In the production of drugs and other healthcare products, maintaining a contamination-free environment is crucial. Filter steel mesh is used extensively to filter out unwanted particulates, ensuring product safety and compliance with stringent industry standards.

Benefits of Using Filter Steel Mesh

The advantages of filter steel mesh in industrial applications cannot be overstated. By employing this technology, businesses can enhance their operational efficiency, improve product quality, and reduce costs associated with equipment maintenance and replacement. Additionally, the longevity and durability of filter steel mesh translate into lower overall lifecycle costs.

Moreover, as industries are increasingly focused on sustainability and reducing waste, filter steel mesh contributes positively to these goals. Its reusability and ease of maintenance mean fewer materials are discarded, aligning with eco-friendly practices.

Conclusion

In conclusion, filter steel mesh is a vital component across various industries, offering exceptional filtration capabilities, durability, and customization options. Its application in water treatment, food processing, chemicals, and pharmaceuticals showcases its versatility and importance in modern manufacturing and production processes. As industries continue to evolve, filter steel mesh will undoubtedly play a pivotal role in meeting filtration demands efficiently and effectively, securing its place as an indispensable asset in today's industrial toolkit.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025