-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Benefits and Applications of Filter Steel Mesh in Various Industries

The Importance of Filter Steel Mesh in Industrial Applications

In various industrial processes, the significance of filter steel mesh cannot be overstated. This versatile material plays a critical role in separating particles, ensuring product quality, and enhancing production efficiency. Understanding the properties, applications, and benefits of filter steel mesh is essential for industries ranging from food and beverage to pharmaceuticals and chemicals.

What is Filter Steel Mesh?

Filter steel mesh is a type of woven wire mesh commonly made from stainless steel or other alloys. Its construction consists of interlaced wires that create a grid-like pattern with precise openings, which can be customized to meet specific filtration needs. The mesh is durable, resistant to corrosion, and can withstand high pressures and temperatures, making it ideal for various industrial settings.

Applications in Different Industries

Filter steel mesh finds extensive applications in multiple sectors.

1. Food and Beverage Industry In food processing, filter steel mesh is crucial for the separation of solids from liquids, allowing for a clear and refined product. It is used in brewing processes, juice extraction, and even in the production of dairy products, where the mesh ensures that unwanted particulates are removed.

2. Pharmaceutical Industry The pharmaceutical sector requires highly purified ingredients. Filter steel mesh is utilized in processes such as drug formulation and the production of vaccines to filter out contaminants and ensure that the final product adheres to stringent safety standards.

3. Chemical Industry In chemical manufacturing, filter steel mesh plays a vital role in preventing contaminants from affecting the quality of chemical compounds. It is used in processes like liquid filtration, catalyst recovery, and recycling processes.

4. Water Treatment Another critical application is in water treatment plants where filter steel mesh is used to separate impurities from water, ensuring that only clean water is distributed for consumption. The mesh assists in both the initial filtration of raw water and the final purification stages.

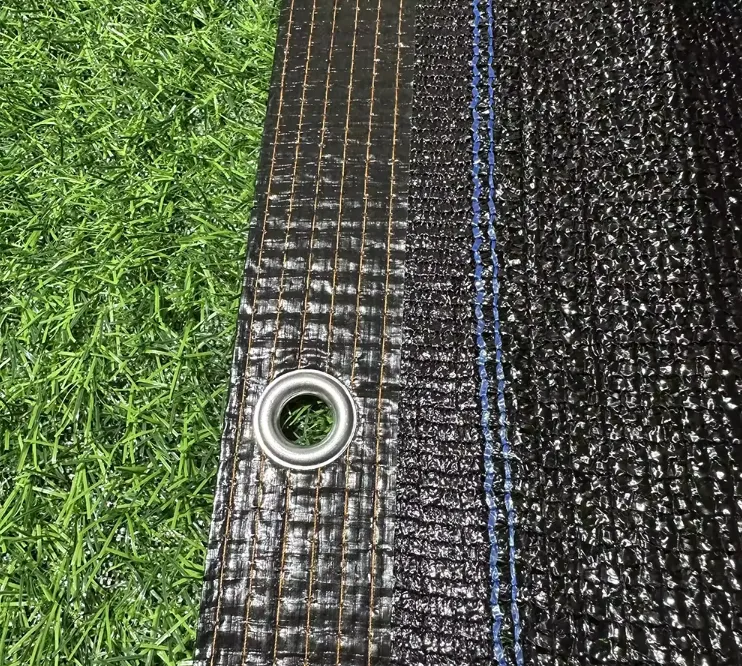

filter steel mesh

5. Oil and Gas In the oil and gas industry, filter steel mesh is used in the refinement process to separate impurities from crude oil and in the filtration of drilling fluids, ensuring that equipment operates efficiently and safely.

Benefits of Using Filter Steel Mesh

The benefits of employing filter steel mesh in industrial applications are numerous

- Efficiency The precise opening sizes of filter steel mesh allow for efficient separation of solids and liquids, thus improving operational efficiency. This can lead to reduced processing times and enhanced throughput.

- Durability Made from high-quality materials, filter steel mesh is designed to withstand harsh conditions, including high temperatures and corrosive substances. This durability translates to longer lifespan and reduced maintenance costs.

- Customizability Filter steel mesh can be manufactured in various sizes and mesh configurations to meet specific filtration requirements. This flexibility enables industries to adapt their filtration processes to suit their unique needs.

- Cost-Effectiveness By improving product quality and process efficiency, filter steel mesh can lead to significant cost savings. Lower maintenance needs and reduced waste translate into a higher return on investment.

Conclusion

In summary, filter steel mesh is an indispensable component in many industrial applications. Its effectiveness in separating particles and ensuring product quality cannot be overlooked. As industries continue to seek higher efficiency and stricter quality control, the demand for high-quality filter steel mesh will undoubtedly increase. Companies that prioritize the implementation of effective filtration solutions will not only enhance their operational processes but also contribute to a broader commitment to product excellence and customer satisfaction. Understanding the role of filter steel mesh is thus critical for those involved in the design and implementation of efficient industrial systems.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025