-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

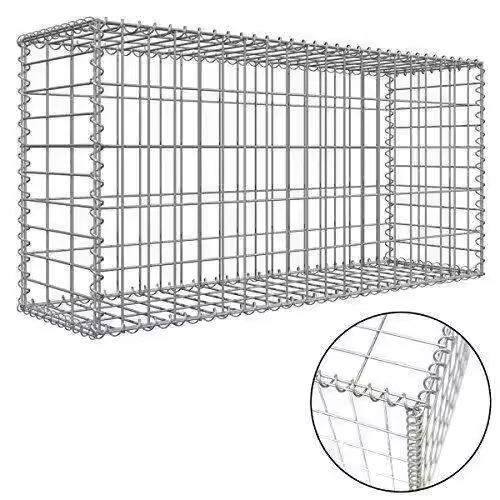

fine screen mesh stainless steel

The Benefits and Applications of Fine Screen Mesh Stainless Steel

Fine screen mesh stainless steel is a highly versatile material that has gained significant popularity across various industries due to its durability, corrosion resistance, and excellent filtration capabilities. This specialized mesh is manufactured using high-quality stainless steel, which provides not only strength but also adaptability to a range of environments and conditions. In this article, we will explore the benefits and multiple applications of fine screen mesh stainless steel.

What is Fine Screen Mesh Stainless Steel?

Fine screen mesh stainless steel is characterized by its tightly woven wire fibers that form a mesh. The opening sizes can vary, allowing it to be used for different filtration needs. Typically, it is made from austenitic stainless steel, which is known for its remarkable resistance to rust and oxidation. The precise weaving of the wire guarantees a strong yet flexible mesh that can withstand mechanical stress without compromising its structural integrity.

Advantages of Fine Screen Mesh Stainless Steel

1. Corrosion Resistance One of the most notable features of stainless steel is its resistance to corrosion. This makes fine screen mesh ideal for use in humid or damp environments where other materials would rust and deteriorate over time.

2. High Strength The strength of stainless steel allows the fine screen mesh to bear significant loads while maintaining its shape. This property is particularly beneficial in applications where the mesh must withstand high pressures or impact.

3. Durability Fine screen mesh made from stainless steel is designed to last for extended periods, even under harsh conditions. It does not easily degrade, making it a cost-effective solution in the long run.

4. Versatility With a variety of wire diameters and mesh sizes available, fine screen mesh can be tailored to specific requirements. Whether for filtration, support structures, or protective screens, its versatility makes it a go-to option in many industries.

5. Ease of Cleaning The smooth surface of stainless steel prevents the accumulation of dirt and contaminants, making it easy to keep the mesh clean. This is particularly advantageous in sanitary applications, such as food processing or pharmaceuticals.

fine screen mesh stainless steel

Applications of Fine Screen Mesh Stainless Steel

- Filtration Perhaps the most common application, fine screen mesh is extensively used for filtering liquids and gases in various industries. In water treatment facilities, for example, it helps in removing pollutants and debris from water sources.

- Food Industry In food processing, the mesh is vital for ensuring the safety and cleanliness of the products. It is used in sieving, draining, and filtering applications, ensuring that food products are free from impurities.

- Pharmaceuticals The pharmaceutical industry utilizes fine screen mesh in processes where contamination-free environments are essential. It is used for filtering active ingredients and ensuring the integrity of the final product.

- Mining and Aggregates In mining, fine screen mesh is employed to separate materials by size. Its strength and durability ensure that it can handle harsh processing environments without degradation.

- Construction Fine screen mesh is also used in construction for a range of applications, including reinforcement and protection. It can be used in concrete to control cracking and ensure product longevity.

- Automotive and Aerospace In these sectors, fine screen mesh is utilized for filtration systems in fuel and oil applications, ensuring that only clean fluids flow through engines and components.

Conclusion

Fine screen mesh stainless steel is a reliable and essential material in various applications across multiple industries. Its inherent properties, including corrosion resistance, strength, and ease of maintenance, make it a preferred choice for filtration and other uses. As industries continue to evolve and require more specialized materials, the importance and utility of fine screen mesh stainless steel will undoubtedly grow, contributing to advancements in technology and product quality across the board. Whether in manufacturing, food processing, or environmental conservation, this mesh serves as a testament to the enduring potential of stainless steel in modern applications.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025