-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

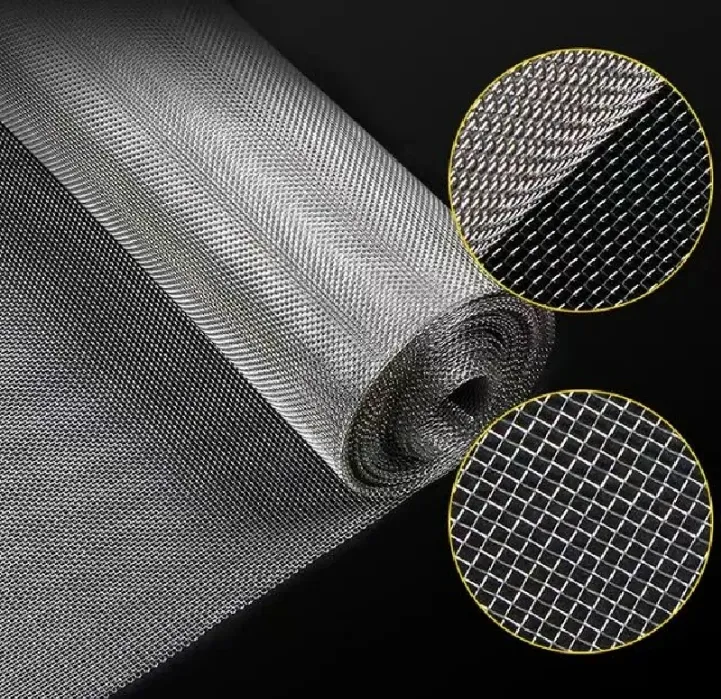

fine stainless steel mesh screen

Fine Stainless Steel Mesh Screen An Overview

Fine stainless steel mesh screens are versatile and essential components widely used in various industries, from food and beverage processing to pharmaceuticals and filtration systems. Their remarkable durability, resistance to corrosion, and fine filtration capabilities make them an ideal choice for applications requiring precision and reliability.

Composition and Design

Fine stainless steel mesh is manufactured from high-quality stainless steel, typically 304 or 316 grades, which are known for their excellent mechanical properties and resistance to rust and tarnish. The mesh is woven in a way that allows for different hole sizes, providing varying levels of filtration. The configurations can range from very fine to relatively coarse, depending on the specific application and filtration requirements.

The design of these mesh screens includes a series of parallel wires, both horizontally and vertically, creating openings that can filter out specific particle sizes. This design not only ensures stability and strength but also maintains consistent flow rates, making it perfect for processes needing both efficiency and effectiveness.

Applications

1. Filtration Systems In industries such as water treatment, oil refining, and chemical processing, fine stainless steel mesh is used to filter out impurities and maintain the quality of fluids. Its ability to withstand harsh chemicals and high temperatures makes it invaluable in these sectors.

2. Food and Beverage Production The use of fine stainless steel mesh in the food industry is crucial for ensuring product safety and hygiene. These screens are commonly used in the production of beverages, dairy products, and any application that requires fine straining or separation. The non-reactive nature of stainless steel means that no unwanted flavors or substances leach into food products.

3. Pharmaceuticals In the pharmaceutical industry, maintaining cleanliness and sterility is paramount. Fine stainless steel mesh screens are used for filtration and separation of active ingredients and other components, ensuring that products meet stringent regulatory standards.

fine stainless steel mesh screen

4. Mining and Mineral Processing These mesh screens are also applicable in mining, where they help in the separation of granular materials and ores. Their strength and resistance to wear make them an ideal choice for such rugged applications.

Advantages

- Durability One of the foremost advantages of fine stainless steel mesh is its durability. Its resilience to corrosion and wear ensures a long service life, reducing the need for frequent replacements.

- Versatility The versatility of fine stainless steel mesh screens allows them to be tailored to a wide range of applications. Different weaves and hole sizes can be manufactured to meet specific needs, making them suitable for various industries.

- Strength and Stability The mechanical strength of stainless steel means that these meshes can handle significant pressures and physical stresses, making them suitable for demanding environments.

- Easy Maintenance Stainless steel mesh screens are easy to clean and maintain, often taking simply a wash or rinse to keep them in good working order, which minimizes downtime in operational processes.

Conclusion

In summary, fine stainless steel mesh screens play a crucial role across numerous sectors, providing robust solutions for filtration, safety, and efficiency. Their combination of durability, versatility, and ease of maintenance makes them indispensable in modern industrial practices. With ongoing innovations in materials and manufacturing processes, the future of fine stainless steel mesh screens looks promising, continuing to enhance productivity and safety across various applications.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025