-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Gabion Wire Specifications for Optimal Strength and Durability in Construction

Gabion Wire Specification A Comprehensive Overview

Gabions, which are wire mesh containers filled with rock, concrete, or other materials, are increasingly popular in various engineering and landscaping applications. These structures offer significant utility in erosion control, stabilization of slopes, and as decorative elements in landscaping. The effectiveness of a gabion is heavily reliant on the specifications of the wire used in construction. This article delves into the key components of gabion wire specifications, ensuring that those seeking to utilize gabions can make informed decisions.

Material Composition

Gabion wire is primarily composed of steel. Commonly used materials include low carbon steel wire, which is characterized by its ductility and tensile strength. In environments where corrosion is a concern, galvanized steel wire is often the preferred choice. The galvanization process involves coating the steel with zinc to enhance its resistance to rust and other forms of corrosion. This is especially important in waterside applications or areas with high moisture content. Additionally, some companies offer polymer-coated wire, which provides an extra layer of protection against environmental factors.

Wire Gauge and Diameter

The diameter of gabion wire is a critical specification that affects both the strength and durability of the structure. Wire gauges typically range from 2.0 mm (12 gauge) to 4.0 mm (8 gauge), depending on the application and filling materials. Thicker wires offer improved structural integrity, whereas thinner wires might be more suitable for smaller, decorative gabion applications. Manufacturers often specify wire diameter in millimeters or inches, and it is essential to choose the appropriate gauge based on load requirements and environmental conditions.

Tensile Strength

gabion wire specification

The tensile strength of gabion wire is another vital aspect of its specification. Tensile strength is defined as the maximum amount of tensile (pulling) stress that a material can withstand without breaking. Gabion wire typically has a minimum tensile strength ranging from 350 to 500 MPa (megapascals). Higher tensile strength wire is recommended for applications involving significant loads or in areas subject to extreme weather conditions.

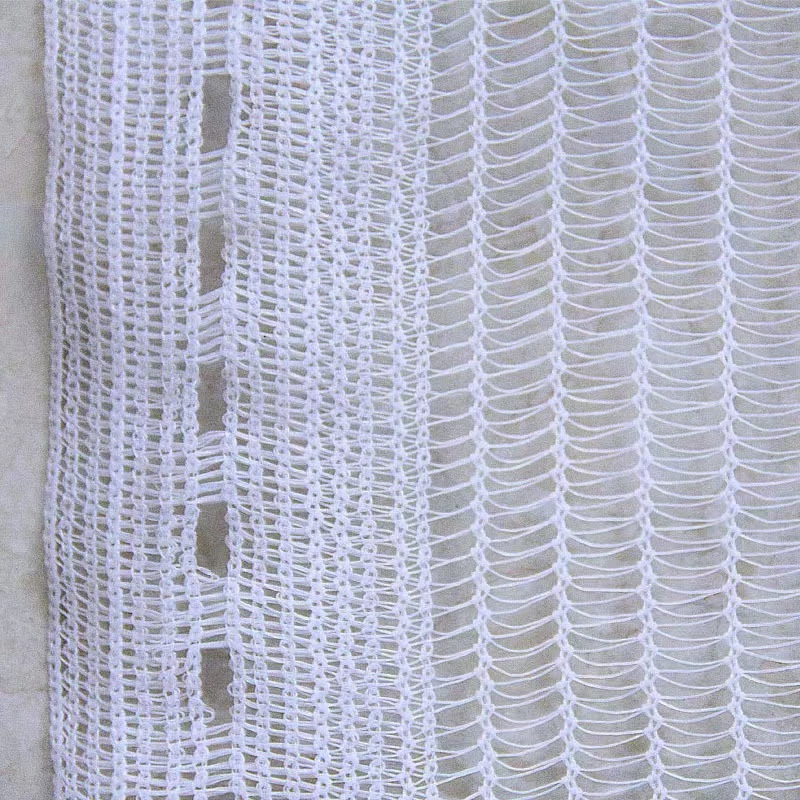

Mesh Size and Opening

Gabion wire is woven into a mesh structure, which serves as the framework for holding the fill material. The size of the mesh openings is crucial for ensuring that smaller stones or fill materials do not escape while still providing adequate drainage and stability. Standard mesh sizes typically range from 6 cm x 6 cm to 10 cm x 10 cm (approximately 2.4 inches to 4 inches). The choice of mesh size depends on the type of fill used, and consideration should also be given to local regulations regarding gabion construction.

Coating and Protection

As previously mentioned, coatings such as galvanization or polymer treatment play a significant role in the longevity of gabion wire. The type and thickness of the coating dictate its lifespan in corrosive environments. For instance, a heavier galvanization might be required in coastal applications where saltwater exposure is prevalent. It is essential that users verify the coating standard, which is sometimes specified in terms of a weight (e.g., grams of zinc per square meter).

Conclusion

Understanding gabion wire specifications is crucial for ensuring the success and longevity of gabion structures. By paying attention to the material composition, wire gauge, tensile strength, mesh size, and protective coatings, users can select the appropriate products for their specific needs. Whether for civil engineering projects, landscaping, or erosion control, the right gabion wire specification can make a significant difference in the overall performance and durability of the installation. In any case, collaborating with reputable manufacturers and suppliers who adhere to industry standards will further enhance the reliability of your project. With the correct specifications in place, gabions can serve as robust and aesthetically pleasing solutions for various applications.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025