Galv Weld Mesh – Durable, Anti-Rust, Factory Direct Prices

Galv Weld Mesh is a key solution in the industrial goods industry, specifically within metal products and Wire mesh products. This article explores how Anping County Yongji Metal Products Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Galv Weld Mesh Overview

- Benefits & Use Cases of Galv Weld Mesh in Wire mesh products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial goods

- Conclusion on Galv Weld Mesh from Anping County Yongji Metal Products Co., Ltd.

Galv Weld Mesh Overview

Galvanized welded mesh (often shortened to Galv Weld Mesh) is a grid of low-carbon steel wires welded at each intersection, then protected with a zinc coating for long-term corrosion resistance. In metal products and, specifically, Wire mesh products, it is the reliable “workhorse” for fencing, partitions, machine guards, screens, and reinforcement where strength, dimensional accuracy, and lifespan matter. Anping County Yongji Metal Products Co., Ltd. manufactures hot-dipped galvanized mesh in both rolls and panels, with common gauges ranging from heavy-duty 6 gauge to versatile 12 gauge, and apertures from fine screening to open panels for structural guarding.

From a technical standpoint, consistent weld integrity and uniform zinc coverage are critical. Yongji’s automated welding ensures square, flat panels with strong fusion at every junction, reducing deformation during transport and fabrication. The hot-dip galvanizing layer helps resist oxidation in humid or outdoor environments, and the mesh can be cut, bent, and framed without losing dimensional stability. Typical supply formats include panel widths up to 2.4 m and roll lengths suitable for rapid site deployment; custom sizes, wire diameters, and aperture combinations are available to align with project specifications and safety standards. For B2B buyers, this translates into fewer rejects, faster installation, and predictable performance across industrial settings.

Benefits & Use Cases of Galv Weld Mesh in Wire mesh products

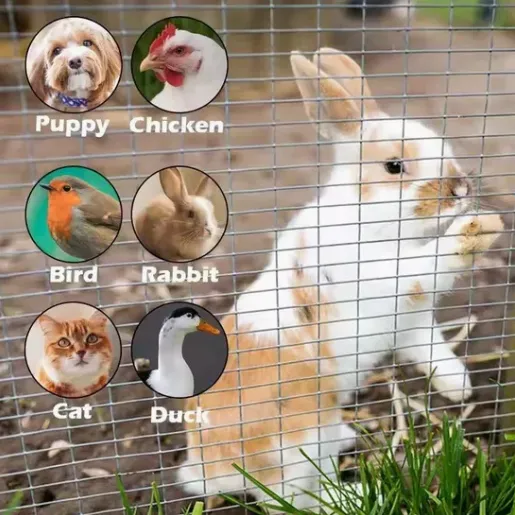

In Wire mesh products, Galv Weld Mesh excels across applications that demand both mechanical strength and corrosion protection. Common use cases include perimeter and security fencing, warehouse partitions, rack and machine guarding, HVAC/ventilation screens, livestock and poultry enclosures, and construction site safety barriers. In food, beverage, and pharmaceutical facilities, its galvanized finish helps minimize rust staining and simplifies washdowns. In infrastructure and utilities, its rigidity and predictable aperture make it ideal for protective covers and equipment cages where visibility and airflow are required without compromising safety.

Key advantages include strong welds that resist impact, a durable zinc coating for outdoor longevity, excellent flatness for clean installation, and easy customization for aperture size, wire gauge, and panel dimensions. Anping County Yongji Metal Products Co., Ltd. leverages strict process control to deliver consistent mesh geometry and coating quality, supporting OEM fabrication, powder-coating post-processing, and just-in-time deliveries. With export-ready packaging and experienced technical support, Yongji helps project teams shorten lead times, meet safety requirements, and maintain uniform appearance across multi-site deployments.

Cost, Maintenance & User Experience

For B2B decision makers, total cost of ownership outweighs initial expense. Galv Weld Mesh typically delivers a lower lifetime cost than uncoated mesh that requires frequent painting or replacement. The zinc layer shields against corrosion, extending service life and reducing downtime for maintenance. Practical drivers of weld mesh price include wire gauge and grade, aperture size, panel vs. roll format, zinc coating method and weight, fabrication (cutting, framing), order volume, and freight. Yongji’s optimized production and stable supply chain enable competitive pricing without compromising mechanical strength or coating integrity, supporting predictable capex and opex planning.

Maintenance is straightforward: periodic inspection in coastal or chemical environments, rinsing to remove contaminants, and cold-galvanizing touch-up on cut edges if required. Many of Yongji’s industrial users report cleaner audits in hygiene-sensitive areas and fewer interventions due to rust, especially compared with painted alternatives. For best results, pair the mesh with compatible galvanized or stainless fasteners to avoid galvanic mismatch. The result is a dependable, low-touch solution that keeps facilities compliant, safe, and visually consistent over time.

Sustainability & Market Trends in industrial goods

Industrial buyers increasingly seek durable products with a smaller environmental footprint. Galvanized welded mesh supports sustainability through long service life (fewer replacements and less waste), recyclability of steel and zinc, and reduced need for solvent-based repainting. As infrastructure upgrades and safety regulations expand globally, demand is growing for compliant, traceable, and consistently finished mesh solutions that help projects meet environmental and safety targets without escalating maintenance cycles.

Anping County Yongji Metal Products Co., Ltd. aligns with these trends by emphasizing efficient manufacturing, careful material utilization, and packaging that protects product quality while minimizing waste. With responsive engineering support and data-driven quoting, Yongji helps buyers quickly evaluate specifications and the weld mesh price impacts of gauge, aperture, and coating weight. This forward-thinking approach ensures customers can balance technical performance, sustainability goals, and budget discipline across complex, multi-site rollouts.

Conclusion on Galv Weld Mesh from Anping County Yongji Metal Products Co., Ltd.

For industrial goods stakeholders, Galv Weld Mesh delivers the right balance of strength, corrosion resistance, and value. Across metal products and Wire mesh products, it enables safer facilities, faster installations, and longer service life with minimal upkeep. Anping County Yongji Metal Products Co., Ltd. stands out for consistent quality, flexible customization, and reliable lead times that help B2B teams stay on schedule and on budget. Ready to specify or compare weld mesh price options for your next project? Contact us: email: admin@yjwiremesh.com — Visit our website: https://www.yjwiremesh.com

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025