-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

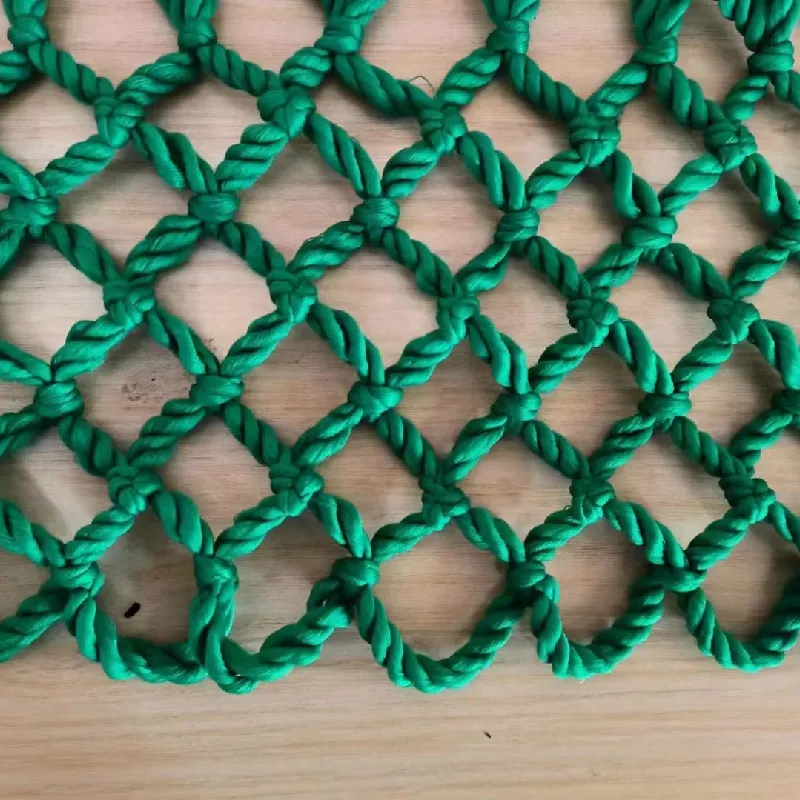

Galvanized Steel Wire Mesh for Versatile Applications in Construction and Security Solutions

The Versatility and Importance of Galvanised Steel Wire Mesh

Galvanised steel wire mesh has long been a fundamental material in various industrial and construction applications, known for its durability, strength, and resistance to corrosion. This specialized mesh is crafted from high-quality steel wire that has undergone a galvanisation process, involving the coating of the wire with a layer of zinc. This protective coating not only enhances the longevity of the wire mesh but also provides a variety of functional benefits that make it a preferred choice for many applications.

One of the primary advantages of galvanised steel wire mesh is its exceptional resistance to rust and corrosion. In environments where moisture and other corrosive substances are prevalent, unprotected steel can deteriorate rapidly. The zinc coating acts as a sacrificial layer, meaning it oxidizes preferentially to the steel, thus providing an additional barrier against environmental stressors. This characteristic makes galvanised steel wire mesh ideal for outdoor applications, such as fencing, landscaping, and construction settings exposed to the elements.

Moreover, the structure of galvanised steel wire mesh is inherently robust. The mesh is available in various sizes, wire thicknesses, and opening configurations, allowing it to accommodate a broad range of uses. It can be employed in agricultural applications, such as creating livestock enclosures or crop protection, where it prevents animals from escaping or intruders from entering while allowing adequate airflow and sunlight. In gardening, it serves as a support framework for climbing plants and as a barrier against pests.

In construction, galvanised steel wire mesh plays a critical role in reinforcing concrete structures. Used as a form of concrete reinforcement, it helps to distribute loads, prevent cracking, and enhance overall structural integrity. This application extends to various forms of construction, including pavements, bridges, and buildings, where safety and durability are paramount.

galvanised steel wire mesh

The versatility of galvanised steel wire mesh extends beyond agriculture and construction. It is commonly utilized in industrial settings for security purposes. Facilities often incorporate this mesh in fencing solutions to create secure perimeters, safeguarding valuable assets from potential theft or vandalism. Additionally, the mesh can be configured into cages to secure tools, machinery, and other essential equipment, ensuring that they remain protected and organized.

Another notable application of galvanised steel wire mesh is within the realm of art and design. Artists and designers have started to explore the aesthetic potential of this material, incorporating it into sculptures, installations, and architectural features. The combination of its strength and flexibility allows for creative expression while still adhering to functional requirements. The mesh can take on various forms, allowing artists to craft intricate designs that echo themes of structure, strength, and transparency.

The manufacturing of galvanised steel wire mesh encompasses not only the initial fabrication of the mesh but also its treatment and coating process. The quality of galvanisation is crucial, as it determines the longevity of the product. Hot-dip galvanisation remains the most effective method, providing a thicker, more durable coating compared to electro-galvanisation. As industries continue to evolve, advancements in galvanisation technology have led to improvements in the efficiency and quality of produced wire mesh.

In conclusion, galvanised steel wire mesh stands out as a versatile, sturdy, and corrosion-resistant material suitable for diverse applications. From enhancing agricultural practices to reinforcing concrete structures and providing security in industrial settings, its benefits are well-recognised across various domains. As reliance on innovative materials continues to grow, galvanised steel wire mesh will undoubtedly maintain its significance, adapting to the changing needs of industries while continuing to inspire creative applications in art and design. Its durability and functionality ensure that it remains a staple in construction and beyond, meeting the demands of a dynamic world.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025