-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

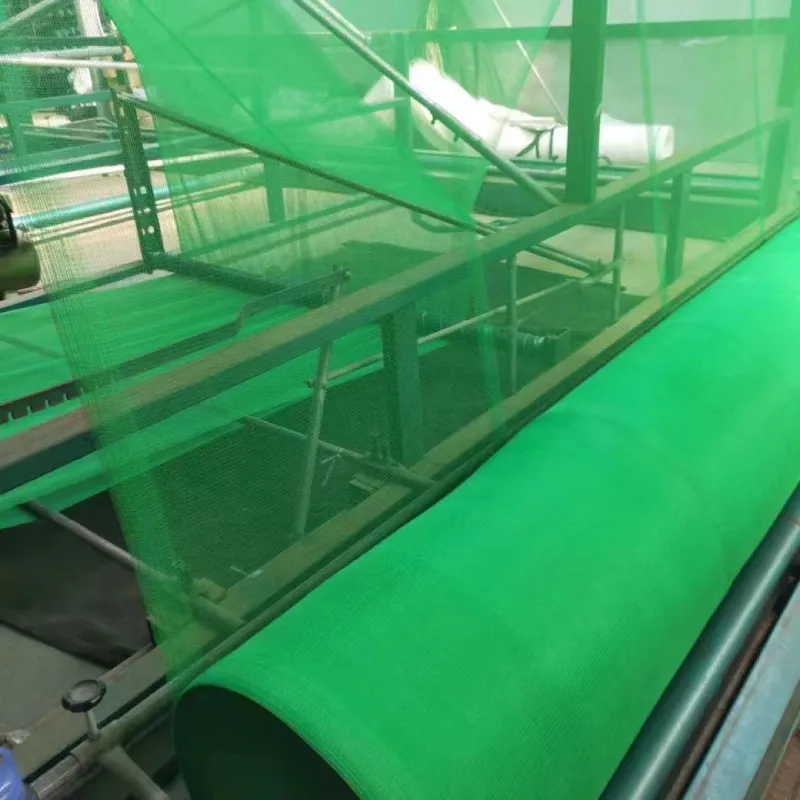

galvanised steel wire mesh

The Versatility and Applications of Galvanised Steel Wire Mesh

Galvanised steel wire mesh is a widely recognized and versatile material that has found applications across a vast array of industries, due to its remarkable properties of strength, durability, and resistance to corrosion. This article will explore the characteristics of galvanised steel wire mesh, its manufacturing process, and its diverse applications.

What is Galvanised Steel Wire Mesh?

Galvanised steel wire mesh is made from steel wires, which are coated with a layer of zinc to protect against corrosion. The galvanisation process involves immersing the steel wire in molten zinc. This forms a protective barrier on the surface of the steel, thereby preventing the onset of rust and extending the material's lifespan. The end result is a robust, reliable mesh product that can withstand harsh environmental conditions.

Manufacturing Process

The production of galvanised steel wire mesh begins with the preparation of high-quality steel wire. This wire is then woven into a grid pattern, with various mesh sizes available to cater to different needs. The manufacturing process can produce different specifications depending on the application, such as wire diameter and mesh opening size. After the mesh is formed, it undergoes the galvanisation process, which not only enhances its resistance to corrosion but also improves its aesthetic appeal with a shiny and clean finish.

Key Advantages

1. Corrosion Resistance The primary benefit of galvanised steel wire mesh is its exceptional resistance to rust and corrosion. The zinc coating acts as a sacrificial anode, which means it corrodes preferentially when exposed to moisture and air, protecting the underlying steel.

3. Versatility This type of mesh can be used for various purposes—ranging from fencing and reinforcing concrete to serving as a barrier in industrial settings. Its adaptability makes it a go-to material in construction, agriculture, and many other sectors.

galvanised steel wire mesh

4. Cost-Effective While the initial costs may be higher than untreated wire, the long lifespan and low maintenance requirements of galvanised wire mesh make it a cost-effective choice in the long run.

Applications

The applications of galvanised steel wire mesh are diverse, spanning various industries. Here are some noteworthy uses

- Construction In the construction industry, galvanised wire mesh is an essential component for reinforcing concrete. It provides added strength and stability, ensuring that structures can withstand heavy loads and turbulent weather conditions.

- Fencing Galvanised steel wire mesh is commonly used for fencing in agricultural settings, providing a sturdy barrier for livestock and crops. Its rust resistance ensures longevity, reducing the need for frequent replacements.

- Industrial Use In factories and warehouses, galvanised steel wire mesh is often used for security fencing, machine guards, and safety barriers, providing protection without obstructing visibility.

- Home Improvement Many homeowners use galvanised steel wire mesh in their gardens and yards, creating decorative trellises, and mesh containers for composting, and even as a protective cover for plants.

- Transportation and Mining In the transportation sector, it is used for highway fencing and noise barriers, while in mining, it often serves as a safety mesh to prevent rock falls.

Conclusion

Galvanised steel wire mesh is an incredibly versatile material that has earned its place in numerous industries due to its strength, durability, and corrosion resistance. As technology advances, the demand for such products continues to grow, reflecting the need for reliable and long-lasting materials in our ever-evolving world. Whether for construction, agriculture, or industrial applications, galvanised steel wire mesh remains a cornerstone of modern engineering and design, making it an invaluable asset in various fields.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025