-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

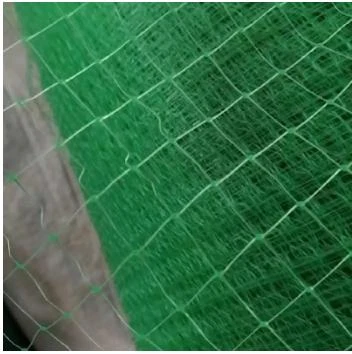

galvanized steel wire mesh

The Importance of Galvanized Steel Wire Mesh in Modern Construction

Galvanized steel wire mesh is a versatile and crucial material widely used in various construction applications. Known for its durability, strength, and resistance to rust and corrosion, galvanized steel wire mesh plays an essential role in ensuring structural integrity and safety across numerous industries.

What is Galvanized Steel Wire Mesh?

Galvanized steel wire mesh is made from steel wires that are coated with a layer of zinc through a process known as galvanization. This coating provides a protective barrier against moisture and elements that could lead to rust and corrosion, extending the lifespan of the mesh. The mesh itself consists of interconnected steel wires, creating openings that vary in size depending on the intended application.

Applications of Galvanized Steel Wire Mesh

There are countless applications for galvanized steel wire mesh, making it a staple in construction and manufacturing.

1. Reinforcement in Concrete One of the primary uses of galvanized steel wire mesh is in reinforcing concrete. When combined with concrete, it increases the tensile strength, helping to prevent cracking and improve overall structural integrity. This makes it an ideal choice in constructing pavements, slabs, and walls.

2. Fencing Galvanized wire mesh is commonly used for fencing due to its strength and resistance to corrosion. It is often employed in residential, commercial, and agricultural settings to secure properties, enclose livestock, and protect gardens.

3. Sifting and Filtering The fine mesh structure allows for applications in sifting and filtering materials, making it an excellent choice for industries such as agriculture and mining. It can sieve sand, gravel, and other granular materials for various uses.

4. Cages and Containers In the manufacturing and logistics sectors, galvanized steel wire mesh is often used to create cages, bins, and containers. These structures are designed to store, transport, and secure goods, providing durability and strength.

galvanized steel wire mesh

5. Architectural Applications Beyond structural uses, galvanized steel wire mesh can also be found in architectural designs. It can be used as decorative facades, walkways, and even in creating art installations, demonstrating its aesthetic appeal in addition to its functional benefits.

Advantages of Galvanized Steel Wire Mesh

The advantages of using galvanized steel wire mesh are numerous

- Corrosion Resistance The zinc coating prevents rust and decay, making it suitable for outdoor applications and environments with high humidity or exposure to chemicals.

- Strength and Durability Galvanized steel wire mesh exhibits remarkable tensile strength, making it capable of withstanding heavy loads and harsh conditions.

- Cost-Effectiveness Due to its long lifespan and low maintenance needs, galvanized steel wire mesh represents a cost-effective solution in the long term, minimizing replacement costs.

- Ease of Installation Galvanized wire mesh is lightweight and easy to handle, simplifying the installation process in various applications.

- Eco-Friendly Option Steel is recyclable, and using galvanized steel wire mesh contributes to sustainable construction practices.

Conclusion

In summary, galvanized steel wire mesh is an indispensable material in modern construction and various industrial applications. Its unique properties, such as durability, corrosion resistance, and versatility, enable it to meet the diverse needs of the construction industry. As technology advances and new uses for this material are discovered, galvanized steel wire mesh will undoubtedly continue to hold significance in creating safe, sustainable, and robust structures that stand the test of time. Whether in reinforcing concrete, constructing fences, or enhancing architectural designs, galvanized steel wire mesh remains a reliable choice for builders and manufacturers alike.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025