-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 05, 2025 03:30

Back to list

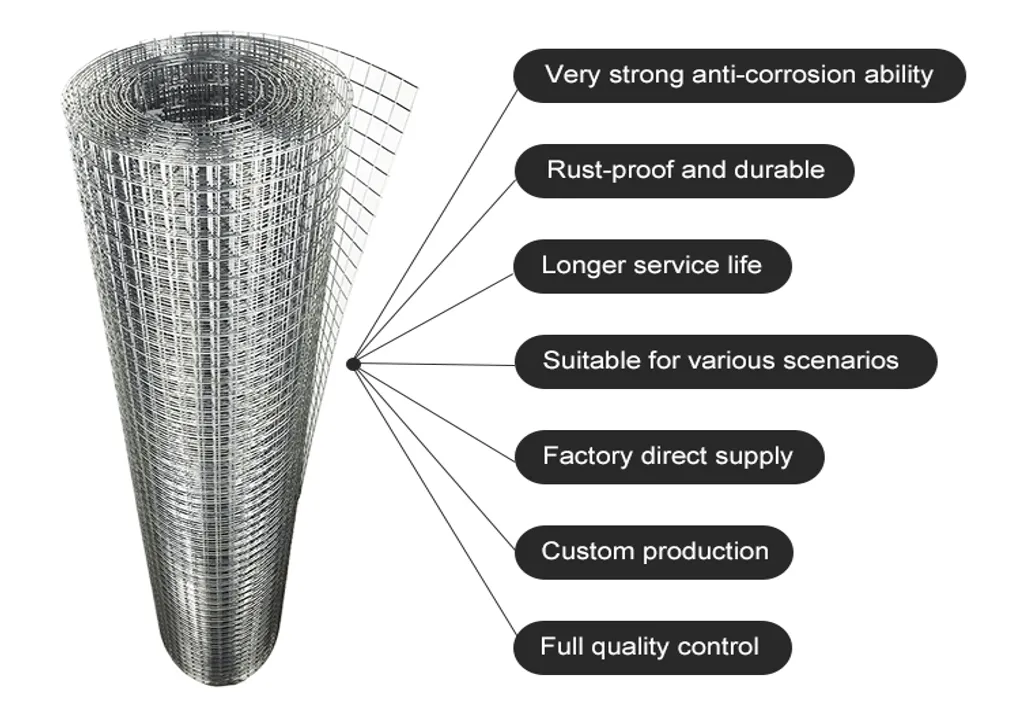

galv weld mesh

Galvanized welded mesh, a product of robust engineering, is revolutionizing a myriad of industries with its unmatched blend of durability, versatility, and cost-efficiency. Constructed by welding low-carbon steel wires at each intersection and then galvanizing it for enhanced protection against corrosion, this material stands as an epitome of design ingenuity and practical application.

Authoritativeness in the market showcases itself through the manufacturer's commitment to innovation and customer service. Leading producers not only design mesh solutions that meet current demands but anticipate future requirements by investing in research and development. This proactive approach results in continuous product improvements, aligning them with emerging industry standards and consumer expectations. Additionally, by offering comprehensive support — from product selection to post-sale service — these companies reinforce their standing as trusted partners in this domain. Their authority is validated by an enduring presence in competitive markets and endorsements from industry experts. Trustworthiness, a cornerstone of consumer decision-making, is vital when selecting galvanized welded mesh. It hinges on the transparency of the production process, the integrity of the material, and the reliability of the supplier. Trust is further cemented by offering guarantees and warranties, ensuring that the mesh performs as specified for a promised duration. Customer feedback and case studies serve as tangible evidence of credibility, highlighting instances where the product has met or exceeded expectations under challenging conditions. An unwavering dedication to ethical practices and honest communication solidifies a manufacturer's reputation, instilling confidence among consumers. In summary, galvanized welded mesh triumphs as a product that combines durability, adaptability, and economic viability without compromising on quality or efficiency. Its application across various sectors underscores its indispensability, supported by a foundation of expert production, authoritative development, and steadfast reliability. As industries evolve, the relevance of galvanized welded mesh remains unabated, continually reasserting itself as an essential component in the fabric of modern infrastructure and beyond.

Authoritativeness in the market showcases itself through the manufacturer's commitment to innovation and customer service. Leading producers not only design mesh solutions that meet current demands but anticipate future requirements by investing in research and development. This proactive approach results in continuous product improvements, aligning them with emerging industry standards and consumer expectations. Additionally, by offering comprehensive support — from product selection to post-sale service — these companies reinforce their standing as trusted partners in this domain. Their authority is validated by an enduring presence in competitive markets and endorsements from industry experts. Trustworthiness, a cornerstone of consumer decision-making, is vital when selecting galvanized welded mesh. It hinges on the transparency of the production process, the integrity of the material, and the reliability of the supplier. Trust is further cemented by offering guarantees and warranties, ensuring that the mesh performs as specified for a promised duration. Customer feedback and case studies serve as tangible evidence of credibility, highlighting instances where the product has met or exceeded expectations under challenging conditions. An unwavering dedication to ethical practices and honest communication solidifies a manufacturer's reputation, instilling confidence among consumers. In summary, galvanized welded mesh triumphs as a product that combines durability, adaptability, and economic viability without compromising on quality or efficiency. Its application across various sectors underscores its indispensability, supported by a foundation of expert production, authoritative development, and steadfast reliability. As industries evolve, the relevance of galvanized welded mesh remains unabated, continually reasserting itself as an essential component in the fabric of modern infrastructure and beyond.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025