-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

gi weld mesh price

Understanding the Prices of GI Weld Mesh A Comprehensive Guide

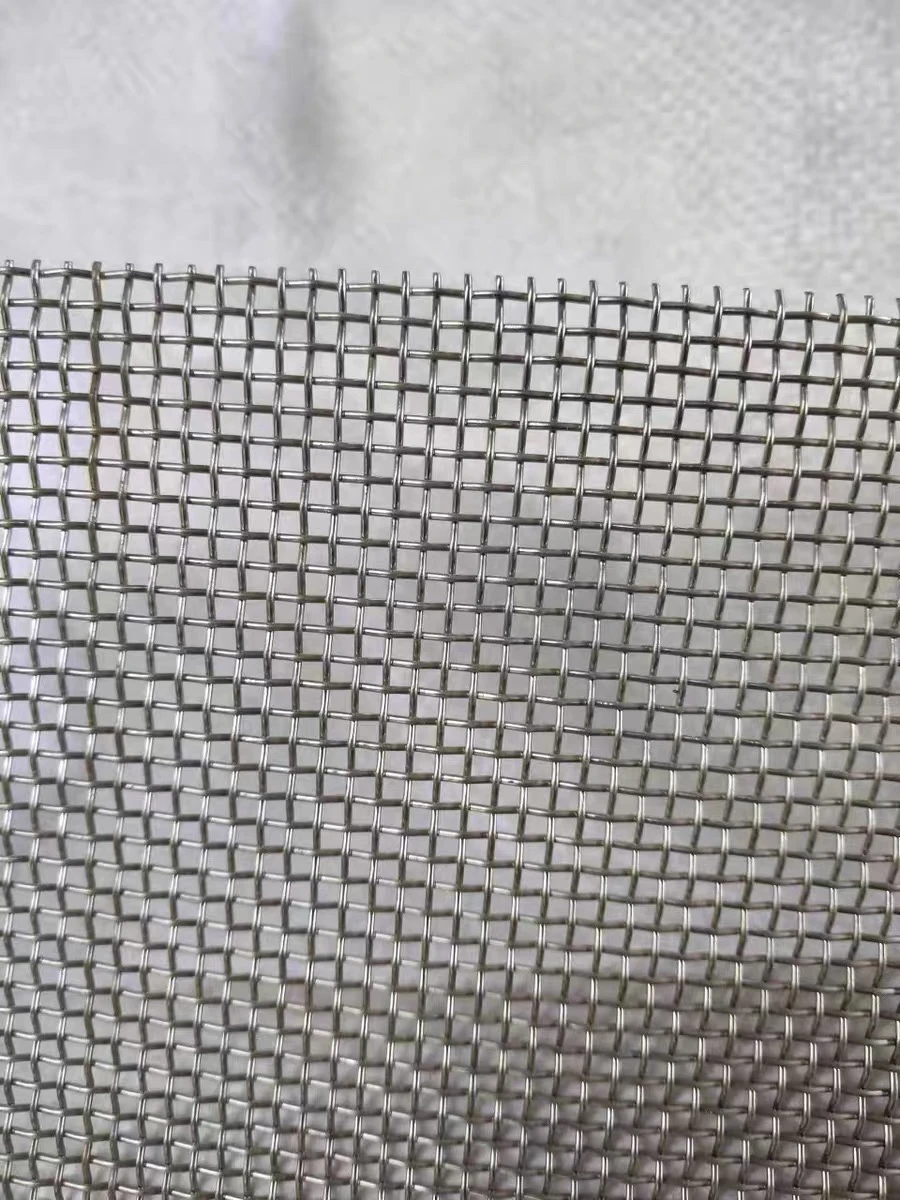

Galvanized iron (GI) weld mesh is a popular choice in various construction and fencing applications due to its durability, strength, and resistance to rust and corrosion. Its myriad uses range from security fencing to agricultural purposes, making it a staple in many industries. However, the pricing of GI weld mesh can be influenced by numerous factors. In this article, we will explore the key elements that affect its price and what you can expect when purchasing.

Materials and Manufacturing Processes

One of the primary factors that influence the price of GI weld mesh is the type of raw materials used in its production. The mesh is made of high-quality iron wire that undergoes a galvanization process to enhance its resistance to corrosion. The quality and thickness of the wire, as well as the coating of zinc used during galvanization, significantly impact the pricing. Higher quality wire with a thicker layer of zinc tends to cost more but delivers longer-lasting performance.

The manufacturing process itself also plays a crucial role. Automated manufacturing systems are generally more efficient, reducing labor costs and production time. However, less automated systems may offer more customizability in terms of mesh size and design, potentially leading to higher prices. When considering the price, it is essential to weigh the advantages of different manufacturing processes.

Market Demand and Supply

Like any commodity, the prices of GI weld mesh are subject to market dynamics, particularly supply and demand. During construction booms or periods of increased agricultural activity, the demand for GI weld mesh can rise significantly, resulting in higher prices. Conversely, during times of economic downturn, demand may decline, leading to lower prices. The availability of raw materials, particularly iron and zinc, can also impact market prices.

gi weld mesh price

Transport costs must also be factored into the final price of GI weld mesh. If the product needs to be shipped over long distances or through challenging logistics, added transportation expenses can also influence the cost. Thus, sourcing from local suppliers may sometimes result in better pricing due to reduced shipping expenses.

Applications and Variants

The price of GI weld mesh can also vary based on its applications and specific variants. For instance, different mesh sizes, such as 1-inch or 2-inch spacing, may be priced differently. The intended use can also dictate the type of mesh required. For example, GI weld mesh intended for agricultural fencing may be priced differently compared to that designed for industrial applications. Additionally, specialized coatings or finishes aimed at enhancing durability in specific environments can also affect the cost.

Regional Differences

Geographical differences can also lead to price variations in GI weld mesh. Countries with a higher production capacity or abundant raw materials may offer lower prices, whereas regions relying heavily on imports might see increased costs. It is essential for buyers to consider local pricing trends and seek quotations from multiple suppliers to ensure they are receiving a competitive rate.

Conclusion

In conclusion, understanding the pricing of GI weld mesh involves analyzing multiple influencing factors, including material quality, manufacturing processes, market dynamics, applications, and regional costs. When planning a purchase, potential buyers should conduct thorough research, compare prices from various suppliers, and consider the long-term benefits of investing in higher-quality products. By doing so, they can ensure they select the best option that suits both their budget and their project requirements. Ultimately, investing in high-quality GI weld mesh can provide enhanced security, longevity, and satisfaction in its performance across various applications.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025