-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

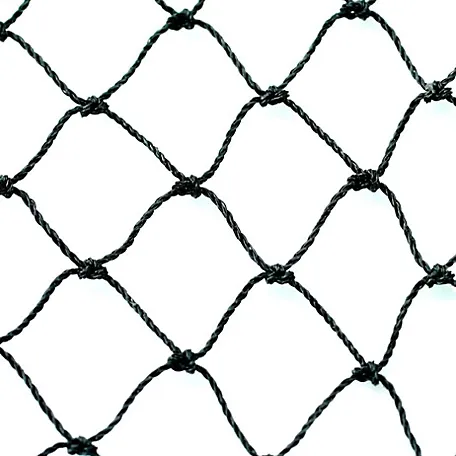

heavy duty stainless steel wire mesh

The Versatility and Strength of Heavy Duty Stainless Steel Wire Mesh

In today's industrial and commercial sectors, the use of heavy-duty stainless steel wire mesh has become increasingly prevalent. This versatile material offers a combination of strength, durability, and resistance to corrosion that makes it ideal for a multitude of applications. From construction sites to food processing plants, the utility of stainless steel wire mesh cannot be overstated. This article explores the various features, benefits, and applications of heavy-duty stainless steel wire mesh.

What is Heavy Duty Stainless Steel Wire Mesh?

Heavy-duty stainless steel wire mesh is made from high-quality stainless steel, often featuring a higher gauge than regular wire mesh. This increased thickness enhances its strength and load-bearing capabilities, making it suitable for demanding applications. The stainless steel composition ensures that the mesh remains resistant to rust and corrosion, which is particularly advantageous in environments exposed to moisture, chemicals, and harsh weather conditions.

The wire mesh typically features an open grid pattern, allowing for airflow and visibility while maintaining structural integrity. The mesh is also available in various weaves, including plain, twill, and Dutch weaves, each providing different characteristics in terms of strength and filtration capabilities.

Key Benefits

1. Corrosion Resistance One of the most notable advantages of stainless steel wire mesh is its resistance to rust and corrosion. This property is especially important in environments where the mesh is subject to moisture or corrosive substances, ensuring a long lifespan with minimal maintenance.

2. Strength and Durability Heavy-duty stainless steel mesh is designed to withstand high levels of stress and strain. Its robust nature makes it an excellent choice for applications requiring the secure containment of heavy materials or continuous usage in demanding settings.

3. Non-Reactive Properties Stainless steel does not react with most chemicals, making it an ideal choice for food processing and medical environments where hygiene and contamination must be minimized.

heavy duty stainless steel wire mesh

5. Ease of Fabrication Stainless steel wire mesh can be easily cut, formed, and welded, making it customizable for specific needs. This flexibility allows manufacturers and builders to create solutions tailored to their applications.

Applications

The applications of heavy-duty stainless steel wire mesh are vast and varied

- Construction In the building industry, it is often used for reinforcing concrete, ensuring structural integrity while allowing for the necessary airflow and drainage. - Industrial Filtration The mesh is utilized in industries such as oil and gas, water treatment, and pharmaceuticals for filtration processes. Its fine weaves can capture particles while allowing liquids and gases to flow freely.

- Food Processing Its non-reactive and easy-to-clean surface makes stainless steel wire mesh an ideal solution for food and beverage processing plants, where hygiene is paramount.

- Security Fencing Heavy-duty stainless steel mesh is often employed in security applications, offering a robust barrier that deters intruders while allowing visibility and airflow.

- Architectural Design In modern architecture, stainless steel wire mesh can be used for aesthetic purposes, serving as decorative panels, sunshades, or even in artworks, blending functionality with visual appeal.

Conclusion

The heavy-duty stainless steel wire mesh is a remarkable material that combines strength, durability, and versatility. Its resistance to corrosion and non-reactive nature makes it suitable for a wide range of applications across different industries. As technology advances and we look for more efficient, sustainable materials, the demand for stainless steel wire mesh is likely to grow. Whether in construction, food processing, or artistic design, stainless steel wire mesh proves to be an indispensable resource in today’s world, catering to the evolving needs of various sectors while maintaining high standards of performance and safety.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025