-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 25, 2025 04:14

Back to list

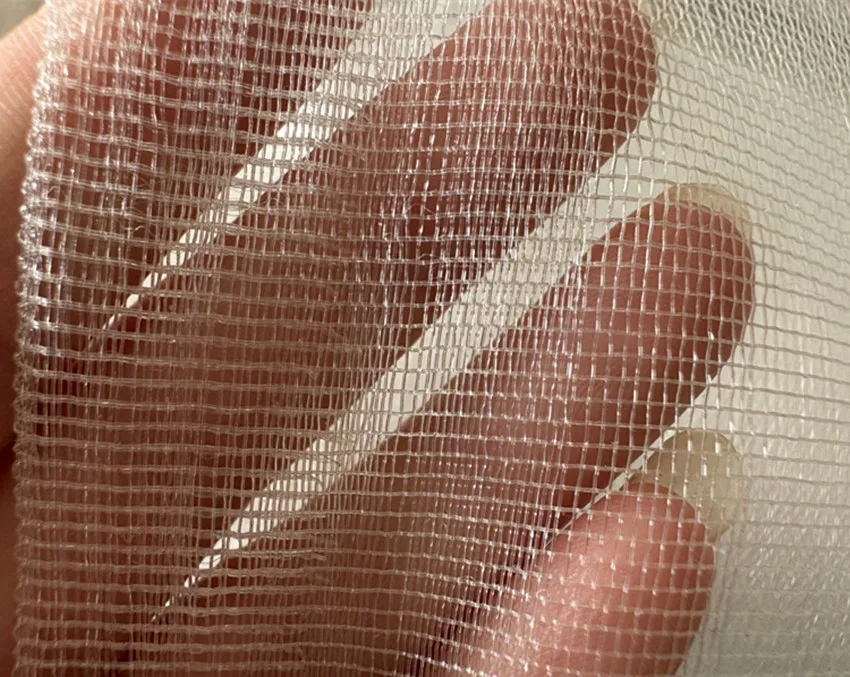

heavy duty bird mesh

A heavy-duty steel mesh screen stands as a critical component in various industrial and commercial applications, offering unparalleled durability, strength, and reliability. These screens are engineered to endure harsh conditions and substantial stress, making them indispensable across sectors such as construction, mining, and security. This article delves into their applications, benefits, and what makes them a top choice for industries requiring robust solutions.

Moreover, the adaptability of these screens is noteworthy. Available in various mesh sizes and wire thicknesses, they can be tailored to meet the specific requirements of a project, whether it involves light filtration or maximum security. Such versatility allows them to be used in diverse applications—from filtration systems in chemical plants to protective covers in machinery—further enhancing their reputation as a multi-functional solution in the industrial realm. Investing in heavy-duty steel mesh screens also signifies a commitment to sustainability. Steel, being recyclable, contributes to resource conservation and the reduction of environmental impact. This aligns with many companies' goals to adopt more sustainable practices while benefiting from a product that meets their operational needs without compromising on quality or performance. For industry professionals seeking authoritative insights into heavy-duty steel mesh screens, understanding their intrinsic qualities is essential. The know-how in selecting the appropriate mesh size, wire gauge, and coatings can greatly affect the effectiveness of the screen in its intended environment. Consulting with manufacturers and suppliers who specialize in these products can provide invaluable information, ensuring that the chosen screen not only meets but exceeds operational expectations. In summary, the heavy-duty steel mesh screen is an integral component for industries demanding high performance and reliability. It is a testament to strength and sturdiness, providing solutions that ensure efficiency and safety in various applications. Its benefits, from corrosion resistance to unmatched durability, make it a wise investment for businesses aiming to optimize operations and secure their assets. The future of industrial applications relies on innovative materials like these, ensuring that industrial processes remain at the forefront of technology and efficiency.

Moreover, the adaptability of these screens is noteworthy. Available in various mesh sizes and wire thicknesses, they can be tailored to meet the specific requirements of a project, whether it involves light filtration or maximum security. Such versatility allows them to be used in diverse applications—from filtration systems in chemical plants to protective covers in machinery—further enhancing their reputation as a multi-functional solution in the industrial realm. Investing in heavy-duty steel mesh screens also signifies a commitment to sustainability. Steel, being recyclable, contributes to resource conservation and the reduction of environmental impact. This aligns with many companies' goals to adopt more sustainable practices while benefiting from a product that meets their operational needs without compromising on quality or performance. For industry professionals seeking authoritative insights into heavy-duty steel mesh screens, understanding their intrinsic qualities is essential. The know-how in selecting the appropriate mesh size, wire gauge, and coatings can greatly affect the effectiveness of the screen in its intended environment. Consulting with manufacturers and suppliers who specialize in these products can provide invaluable information, ensuring that the chosen screen not only meets but exceeds operational expectations. In summary, the heavy-duty steel mesh screen is an integral component for industries demanding high performance and reliability. It is a testament to strength and sturdiness, providing solutions that ensure efficiency and safety in various applications. Its benefits, from corrosion resistance to unmatched durability, make it a wise investment for businesses aiming to optimize operations and secure their assets. The future of industrial applications relies on innovative materials like these, ensuring that industrial processes remain at the forefront of technology and efficiency.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025