-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

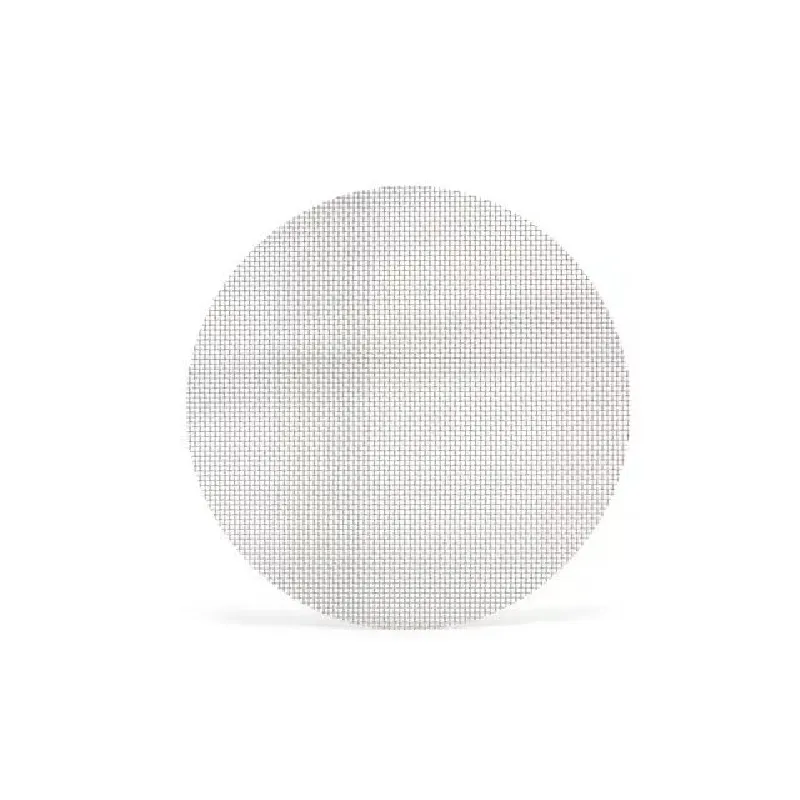

High Efficiency 50 Micron Stainless Steel Filter for Industrial and Food Processing Applications

The Significance of 50 Micron Stainless Steel Filters in Various Industries

In today's fast-paced industrial landscape, efficiency, quality, and sustainability are paramount. One critical component that plays a vital role in optimizing processes and ensuring quality control is filtration. Among the myriad of filtration options available, the 50-micron stainless steel filter stands out due to its durability, precision, and versatility. This article delves into the significance of 50-micron stainless steel filters and their applications in various industries.

What is a 50 Micron Stainless Steel Filter?

A 50-micron filter refers to a filtration system that can effectively remove particles larger than 50 microns. The term micron is a unit of measurement equal to one-millionth of a meter, or approximately 0.001 millimeters. Stainless steel, known for its corrosion resistance and strength, is the material of choice for these filters, making them ideal for a wide range of applications, from food processing to chemical manufacturing.

Key Benefits of 50 Micron Stainless Steel Filters

1. Durability and Longevity Stainless steel filters are built to last. Unlike their plastic or paper counterparts, they do not easily corrode, making them suitable for environments exposed to harsh chemicals or extreme temperatures. This durability translates to a longer lifespan, reducing the need for frequent replacements and thus providing cost savings over time.

50 micron stainless steel filter

2. High Filtration Efficiency With a pore size of 50 microns, these filters can effectively capture a significant number of solid particles while maintaining a high flow rate. They strike a balance between filtration efficiency and fluid flow, making them ideal for processes that cannot afford to be slowed down, such as in food and beverage production or water treatment.

3. Reusability One of the standout features of stainless steel filters is their reusability. These filters can be cleaned and reused multiple times without losing their effectiveness. This not only contributes to a reduction in waste but also promotes sustainable practices within industries striving to minimize their environmental impact.

4. Versatile Applications The applications of 50-micron stainless steel filters are vast. In the food and beverage industry, they are used to filter out contaminants from liquids, ensuring product purity and compliance with health regulations. In the chemical industry, these filters are essential for protecting equipment from particulate matter, which can cause damage and lead to costly downtime. Additionally, they are employed in water treatment facilities to enhance the quality of drinking water by removing impurities.

5. Customization Options 50-micron stainless steel filters can be manufactured in various configurations, allowing for customization based on specific industry requirements. This adaptability ensures that companies can find a solution that meets their unique needs without compromising performance.

Conclusion

In conclusion, 50-micron stainless steel filters offer a reliable solution for industries that prioritize efficiency, safety, and sustainability. Their durability, high filtration efficiency, reusability, and versatility make them an indispensable component in various applications, ranging from food production to chemical processing. As industries continue to evolve and demand higher standards, the importance of effective filtration solutions like the 50-micron stainless steel filter will only increase. Investing in such technologies not only enhances operational efficiency but also contributes to a more sustainable and responsible industrial future.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025