High-Quality Stainless Steel Filters and Strainers for Improved Filtration Efficiency and Durability

Stainless Steel Filters and Strainers Essential Components for Fluid Management

Stainless steel filters and strainers play a crucial role in various industrial processes, ensuring the purity and quality of fluids by removing unwanted particles and contaminants. These essential components are widely utilized in sectors such as food and beverage, pharmaceuticals, petrochemicals, and water treatment, each having unique requirements for filtration.

The Importance of Filtration

In any fluid management system, maintaining the integrity of the fluid is paramount. Contaminants such as dirt, rust, sediment, and biological agents can significantly affect system efficiency and product quality. In many applications, even minimal contamination can lead to equipment malfunction, product spoilage, or even health risks. Thus, the integration of stainless steel filters and strainers is essential in preserving operational efficiency and ensuring end product safety.

Why Choose Stainless Steel?

Stainless steel is the material of choice for filters and strainers for several reasons. Firstly, its corrosion resistance ensures longevity and durability even under harsh conditions. Unlike other materials, stainless steel does not rust or degrade over time, making it especially suitable for applications involving water, chemicals, or high temperatures.

Secondly, stainless steel is easy to clean and maintain. Most filters can be cleaned simply by backwashing or visually inspecting and rinsing, allowing for minimal downtime during maintenance. Moreover, stainless steel is fully recyclable, aligning with sustainable practices and reducing environmental impact.

Types of Stainless Steel Filters and Strainers

Stainless steel filters and strainers come in various designs and sizes to meet different operational needs

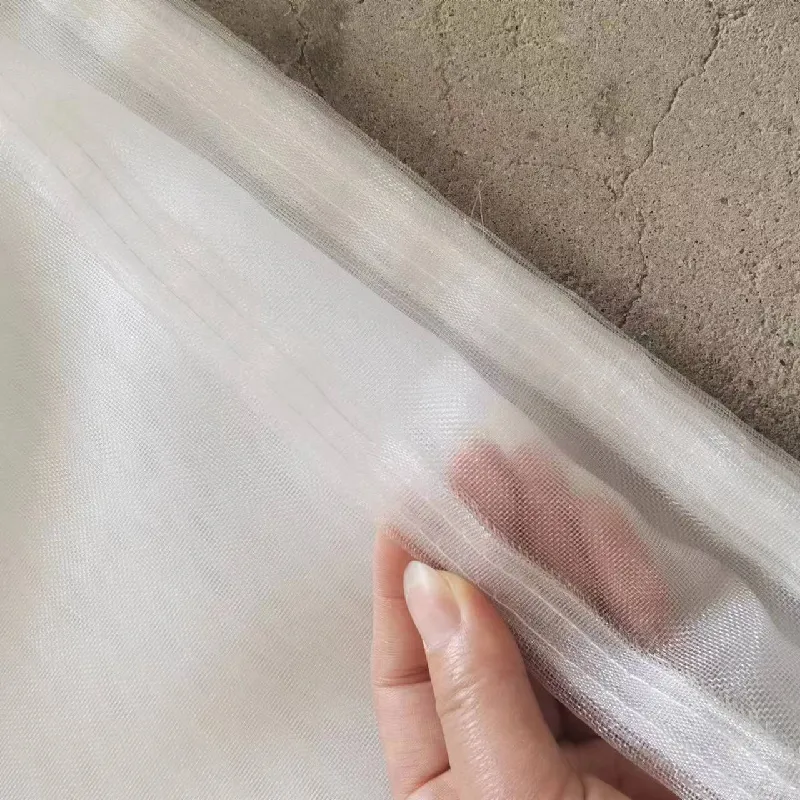

. Some common types include1. Mesh Strainers These are typically used for coarse filtration of larger particles. The mesh size can be customized depending on the application, making them versatile for diverse industrial uses.

stainless steel filters strainers

2. Disc Filters Featuring multiple stacked discs, these filters offer excellent surface area for filtration and are effective in both liquid and gas applications.

3. Bag Filters These systems use a fabric bag to capture contaminants. They are ideal for applications requiring high flow rates and are commonly used in the food and beverage industries.

4. Cartridge Filters Known for their effectiveness in removing very fine particles, cartridge filters can be used in applications where high purity is essential, such as pharmaceuticals and electronics manufacturing.

Applications in Industry

In the food and beverage industry, stainless steel strainers are essential for ensuring that the products meet health and safety standards. They help filter out unwanted solids from liquids, maintaining product quality and extending shelf life.

In pharmaceutical manufacturing, the need for clean and uncontaminated products cannot be overstated. Stainless steel filters ensure that all fluids are free from particulates, protecting both the equipment and the end consumer.

Water treatment facilities rely on stainless steel filtration systems to maintain water quality by removing impurities and protecting downstream equipment from clogging and damage.

In petrochemical processing, stainless steel filters are used to separate process fluids from contaminants that can interfere with production efficiency, thereby playing a vital role in maintaining system integrity.

Conclusion

Stainless steel filters and strainers are indispensable tools for managing fluid quality across various industries. Their robustness, ease of maintenance, and effectiveness in filtration make them a preferred choice for ensuring operational efficiency and product safety. With ongoing advancements in filtration technology, the role of stainless steel filters in improving industrial processes and safeguarding health standards will only continue to grow. Businesses can benefit significantly from investing in high-quality filtration systems, enhancing their production capabilities while adhering to regulatory standards.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025