-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

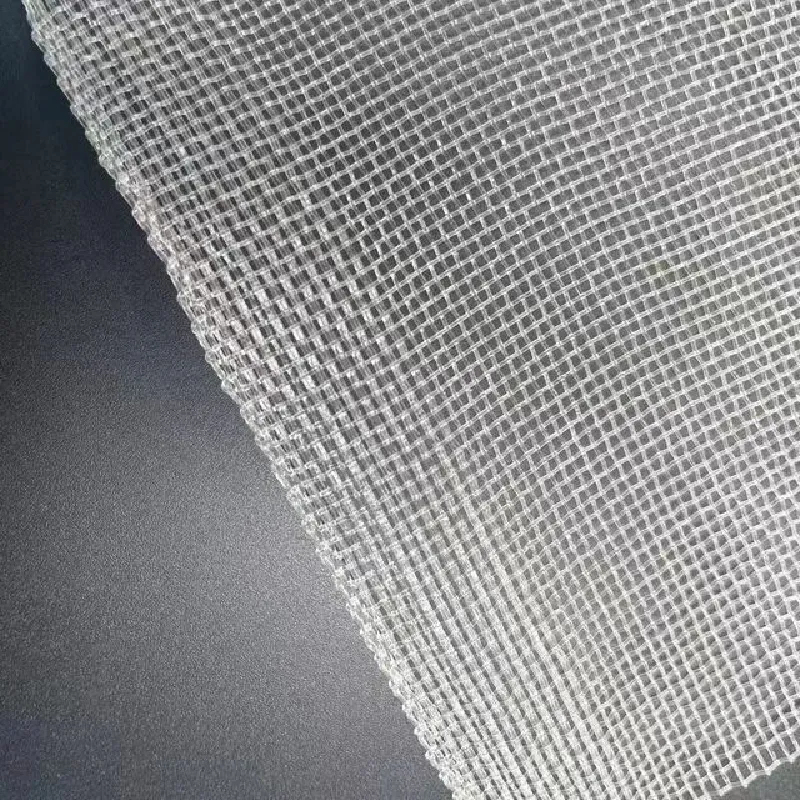

High-Quality Stainless Steel Mesh Screen for Versatile Filtration and Separation Applications

Understanding Fine Stainless Steel Mesh Screens

Fine stainless steel mesh screens are essential components in various industries, where they serve a range of purposes, including filtration, separation, and screen printing. The versatility and durability of stainless steel make it an ideal material for producing high-quality mesh screens that can withstand harsh working conditions while maintaining their structural integrity.

Composition and Characteristics

Stainless steel mesh screens are typically made from steel alloys that contain a minimum of 10.5% chromium, which provides resistance to corrosion and oxidation. Common grades of stainless steel used in mesh production include 304 and 316. Grade 304 is known for its excellent corrosion resistance and formability, making it suitable for general applications. In contrast, grade 316 includes molybdenum, enhancing its resistance to chloride environments, making it ideal for marine applications or areas exposed to aggressive chemicals.

The fineness of the mesh is determined by the size of the openings and the diameter of the wire used in the weave. Mesh screens can range from very fine to coarse, with finer meshes typically used for filtering small particles or contaminants from liquids and gases. The combination of high strength, durability, and resistance to wear makes stainless steel mesh screens an invaluable material in manufacturing and engineering.

Applications

Fine stainless steel mesh screens find applications across numerous industries

1. Filtration In the food and beverage industry, stainless steel mesh screens are utilized for filtering liquids, ensuring that impurities are removed while allowing the essential components to pass through. In water treatment facilities, these screens help trap sediments and larger particles, providing cleaner water for consumption and distribution.

2. Pharmaceuticals The pharmaceutical industry relies on fine stainless steel mesh screens for filtering and separating products, ensuring that medicines are free from contaminants. The non-reactive nature of stainless steel ensures that the material does not interfere with sensitive compounds, thereby maintaining product integrity.

fine stainless steel mesh screen

3. Oil and Gas In oil and gas applications, stainless steel mesh screens are used to separate solids from liquids and gases during extraction and processing. Their corrosion resistance is critical in these environments, where exposure to harsh chemicals and high temperatures is commonplace.

4. Automotive and Aerospace In the automotive and aerospace industries, these mesh screens are crucial for filtration systems and components requiring precise dimensions and high strength. Stainless steel's lightweight yet robust properties contribute to the overall efficiency and safety of vehicles and aircraft.

5. Construction and Architecture Fine stainless steel mesh screens are also used in architectural applications, providing an aesthetic appeal while ensuring functionality. They can be seen in facades, railings, and as part of security systems, providing both privacy and visibility.

Advantages of Fine Stainless Steel Mesh Screens

One of the primary advantages of fine stainless steel mesh screens is their long lifespan. Unlike plastic or other materials that may degrade, stainless steel maintains its integrity under various environmental conditions. Furthermore, they are easy to clean and can be reused multiple times, which makes them an environmentally friendly option.

Additionally, their ability to be fabricated into various shapes and sizes allows manufacturers to customize mesh screens for specific applications, further enhancing their utility across different fields.

Conclusion

Fine stainless steel mesh screens represent a fusion of durability, versatility, and practicality, making them indispensable in several industries. Their ability to perform under pressure, resist corrosion, and offer effective filtration ensures they remain a go-to choice for professionals seeking reliable solutions. As industries continue to evolve, the role of fine stainless steel mesh screens will undoubtedly expand, underscoring the importance of this fundamental component in modern applications.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025