-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Industrial Mesh Screens for Effective Filtration and Resource Management Solutions

Understanding Industrial Mesh Screens Applications and Benefits

Industrial mesh screens are essential components in various sectors, including manufacturing, construction, mining, and food processing. These screens are made from intertwined wires or fibers, designed to act as barriers while allowing the passage of air, liquid, or smaller particles. They come in various materials, sizes, and configurations, tailored to meet the specific needs of diverse industries. This article explores the applications, benefits, and considerations involved in selecting industrial mesh screens.

Applications of Industrial Mesh Screens

1. Filtration and Separation One of the primary uses of industrial mesh screens is for filtration. In water treatment facilities, for instance, mesh screens help in filtering out contaminants from water, ensuring that the water meets safety standards. In industrial processes, mesh screens separate materials of different sizes, allowing for efficient processing.

2. Vibration Screening In mining and aggregate industries, mesh screens are commonly used on vibrating screens to separate valuable minerals from waste rock. The vibration allows finer materials to pass through the mesh, while larger stones are separated and can be discarded or processed further.

3. Safety Barriers Industrial mesh screens are often employed as safety barriers, protecting workers from potential hazards. They can be used in construction sites to prevent debris from falling or as fencing around hazardous areas.

4. Architectural and Design Elements Beyond functional uses, industrial mesh screens are increasingly seen in architectural applications. They are used in facades and interior design, providing aesthetic appeal while still serving practical purposes such as light filtration and privacy.

5. Food Processing In the food industry, mesh screens are crucial for sifting, sorting, and processing food items. They ensure that products are free from foreign materials and contaminants, improving overall food safety.

Benefits of Industrial Mesh Screens

1. Durability and Longevity Industrial mesh screens are typically made from durable materials such as stainless steel, polypropylene, or aluminum. This resilience contributes to a long service life, making them a cost-effective choice in industrial applications.

2. Versatility Available in various mesh sizes and shapes, these screens can be customized for different applications. Whether it is a fine mesh for filtration or a coarser mesh for separation, there is a mesh screen suitable for nearly every need.

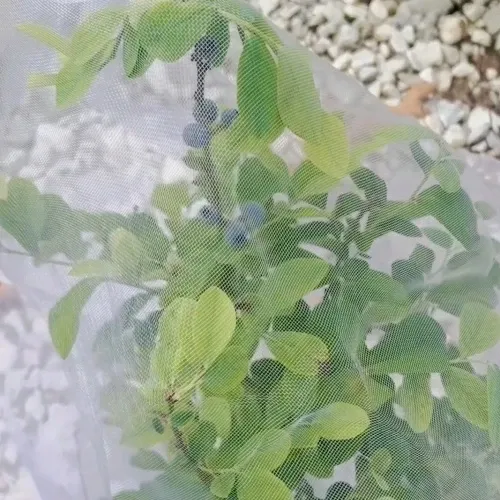

industrial mesh screen

3. Cost Efficiency By improving processes such as filtration or separation, industrial mesh screens can significantly reduce costs associated with waste and downtime. Increased efficiency in operations directly translates to lower overall operational costs.

4. Easy Maintenance Most industrial mesh screens are designed for ease of cleaning and maintenance. Regular maintenance helps in sustaining their efficiency, ensuring that processes remain uninterrupted.

5. Environmental Impact Mesh screens contribute positively to environmental initiatives by ensuring the proper filtration of materials, ultimately leading to lower emissions and contaminants entering water and air systems.

Considerations When Selecting Industrial Mesh Screens

1. Material Choice The choice of material is paramount, as it should align with the specific requirements of the application. For instance, stainless steel is preferable for corrosive environments, while plastics may be suitable for lighter-duty applications.

2. Mesh Size The size of the mesh openings plays a critical role in determining the effectiveness of the screen for its intended application. A finer mesh is necessary for filtration, while a coarser mesh is sufficient for bulk material separation.

3. Design and Construction Factors such as frame strength, flexibility, and overall design can impact the performance and utility of industrial mesh screens. Ensuring that the design fits well within the operational environment is vital.

4. Regulatory Compliance Specific industries, particularly in food and pharmaceuticals, have strict regulatory standards. Ensuring that the chosen mesh screens comply with these regulations is essential for operational legitimacy.

5. Supplier Reputation Working with a reputable supplier can make a substantial difference in the quality of the mesh screens and the support you receive in terms of maintenance and troubleshooting.

Conclusion

Industrial mesh screens are integral to a myriad of applications across various industries, providing filtration, protection, and efficiency. Their durability, versatility, and cost-effectiveness make them invaluable assets in any industrial operation. By understanding their uses and selecting the right materials and designs, companies can enhance their processes, contributing to greater productivity and safety in the workplace. As industries continue to evolve, the role of industrial mesh screens is only expected to grow, underscoring their importance in modern manufacturing and processing environments.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025