-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable Industrial Mesh Screens for Enhanced Filtration and Protection Solutions

Understanding Industrial Mesh Screens Applications, Types, and Benefits

Industrial mesh screens are essential components in various manufacturing and filtration processes. Made from different materials and available in various specifications, these screens serve a multitude of purposes across diverse industries, including food processing, pharmaceuticals, mining, and water treatment. This article explores the different types of mesh screens, their applications, and the benefits they offer.

What is an Industrial Mesh Screen?

An industrial mesh screen is a device consisting of a network of interwoven wires or fibers designed to separate, filter, or protect based on size criteria. These screens can be used for a variety of functions, including filtering liquids or gases, sifting materials, and providing safety barriers in machinery.

Types of Industrial Mesh Screens

1. Woven Wire Mesh This type of screen is produced by weaving wires together, creating a strong and versatile mesh. Made from materials such as stainless steel, aluminum, or copper, woven wire mesh is widely used in filtration and separation processes. It is available in different mesh sizes, which determines the size of the particles that can pass through.

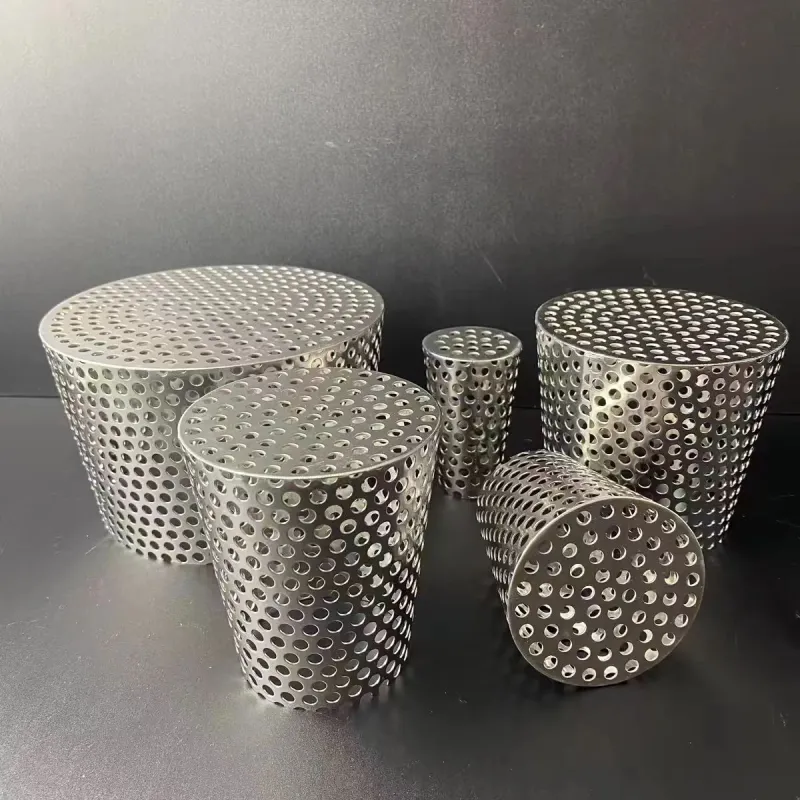

2. Perforated Sheets Perforated metal sheets feature a series of holes punched in them, often in a uniform pattern. These screens are robust and can support heavier loads compared to woven wire meshes. They are commonly used in sieving, screening applications, and as protective barriers in various industrial settings.

3. Fiberglass Mesh This type of mesh offers lightweight and corrosion-resistant properties, making it ideal for many industrial applications, including pool covers, insulation, and as a reinforcement material in plastics. Fiberglass mesh screens provide durability while maintaining flexibility.

4. Polymer Mesh Made from synthetic materials, polymer screens have gained popularity due to their resistance to various chemicals and environmental conditions. They are often used in waste management, food processing, and in environments requiring high levels of cleanliness.

Applications of Industrial Mesh Screens

industrial mesh screen

Industrial mesh screens find applications in numerous sectors

- Filtration Systems These screens are critical in separating solids from liquids or gases, ensuring that processes remain efficient and contaminant-free. - Agriculture and Food Processing Mesh screens are utilized for sorting and grading various agricultural products, as well as in food production for sifting flour or straining fats and oils. - Construction In the construction industry, mesh screens serve as safety barriers and are employed in scaffolding to provide protection where needed. - Mining and Mineral Processing In the extraction of minerals, mesh screens play a crucial role in the separation of ore from waste materials. Benefits of Using Industrial Mesh Screens

The use of industrial mesh screens offers several advantages that can enhance operational efficiency

1. Customization Mesh screens can be customized according to specific applications. Factors like mesh size, opening shape, and material can be tailored to meet precise operational requirements.

2. Increased Efficiency Effective filtration and separation processes result in improved productivity and reduced downtime. Industrial mesh screens help ensure that materials are appropriately processed or filtered, leading to higher quality end products.

3. Cost-Effectiveness Investing in high-quality mesh screens can lead to long-term savings by reducing maintenance requirements and enhancing the lifespan of machinery and filtration systems.

4. Durability and Strength Many industrial mesh screens are designed to withstand harsh conditions, including exposure to chemicals, extreme temperatures, and physical stress. This durability makes them reliable components in challenging environments.

5. Safety When used as protective barriers, mesh screens contribute to workplace safety by preventing accidents and containing hazardous materials, thus protecting both workers and machinery.

Conclusion

Industrial mesh screens are indispensable tools across various sectors. With their diverse types and applications, they not only enhance efficiency and productivity but also contribute significantly to safety and quality control in industrial processes. As industries evolve, the demand for high-performance mesh screens will likely continue to grow, shaping the future of manufacturing and processing technologies. Understanding the significance of these screens and their functionality can help businesses make informed choices, ensuring optimal operation and compliance with industry standards.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025