-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Versatile Mesh Screens for Industrial Applications and Enhanced Filtration Solutions

Understanding Industrial Mesh Screens A Comprehensive Overview

Industrial mesh screens are vital components in various industries, serving multiple purposes, from filtration to reinforcement. These specialized screens are made from different materials and are characterized by their unique mesh patterns, which determine their functionality and suitability for specific applications. This article aims to provide a comprehensive overview of industrial mesh screens, discussing their types, materials, applications, and advantages.

Types of Industrial Mesh Screens

Industrial mesh screens come in various types, each designed for specific uses

1. Woven Wire Mesh Screen This is one of the most common types of industrial mesh. It consists of wires woven together in a grid pattern, providing excellent strength and durability. Woven wire mesh screens are used in filtration, sieving, and as protective barriers in construction.

2. Perforated Metal Screens These screens are made from solid sheets of metal that have been perforated with holes. The size and pattern of the holes can vary, allowing for specific filtration needs. They are often used in applications where strength and structural integrity are crucial, such as in mining and food processing.

3. Expanded Metal Screens Created by cutting and stretching a solid sheet of metal, expanded metal offers a unique combination of strength and lightweight properties. This type of mesh is commonly used in security fencing and architectural applications.

4. Self-cleaning Mesh Screens These are specially designed to prevent clogging and maintain optimal flow. They are typically used in water treatment plants and industrial filtration systems, ensuring efficient operation over time with minimal maintenance.

Materials Used in Industrial Mesh Screens

The choice of material for industrial mesh screens greatly depends on the intended application. Common materials include

- Stainless Steel Renowned for its corrosion resistance and durability, stainless steel is widely used in food processing, chemical industries, and marine applications.

- Carbon Steel This is a cost-effective material suitable for general-purpose use. While it may not resist corrosion as well as stainless steel, it is often coated or treated to improve its longevity.

- Aluminum Lightweight and resistant to corrosion, aluminum mesh screens are used in applications where weight reduction is needed, such as in aerospace and automotive industries.

- Plastic and Fiberglass These materials are often used in environments where corrosion is a concern, such as chemical processing. They offer flexibility and can be produced in various mesh sizes.

industrial mesh screen

Applications of Industrial Mesh Screens

Industrial mesh screens find applications across diverse sectors

- Filtration and Separation Used prominently in water treatment, HVAC systems, and food production, these screens facilitate the separation of solids from liquids or gases

.- Construction and Safety Mesh screens reinforce structures, provide safety barriers, and are used in scaffolding and fencing applications.

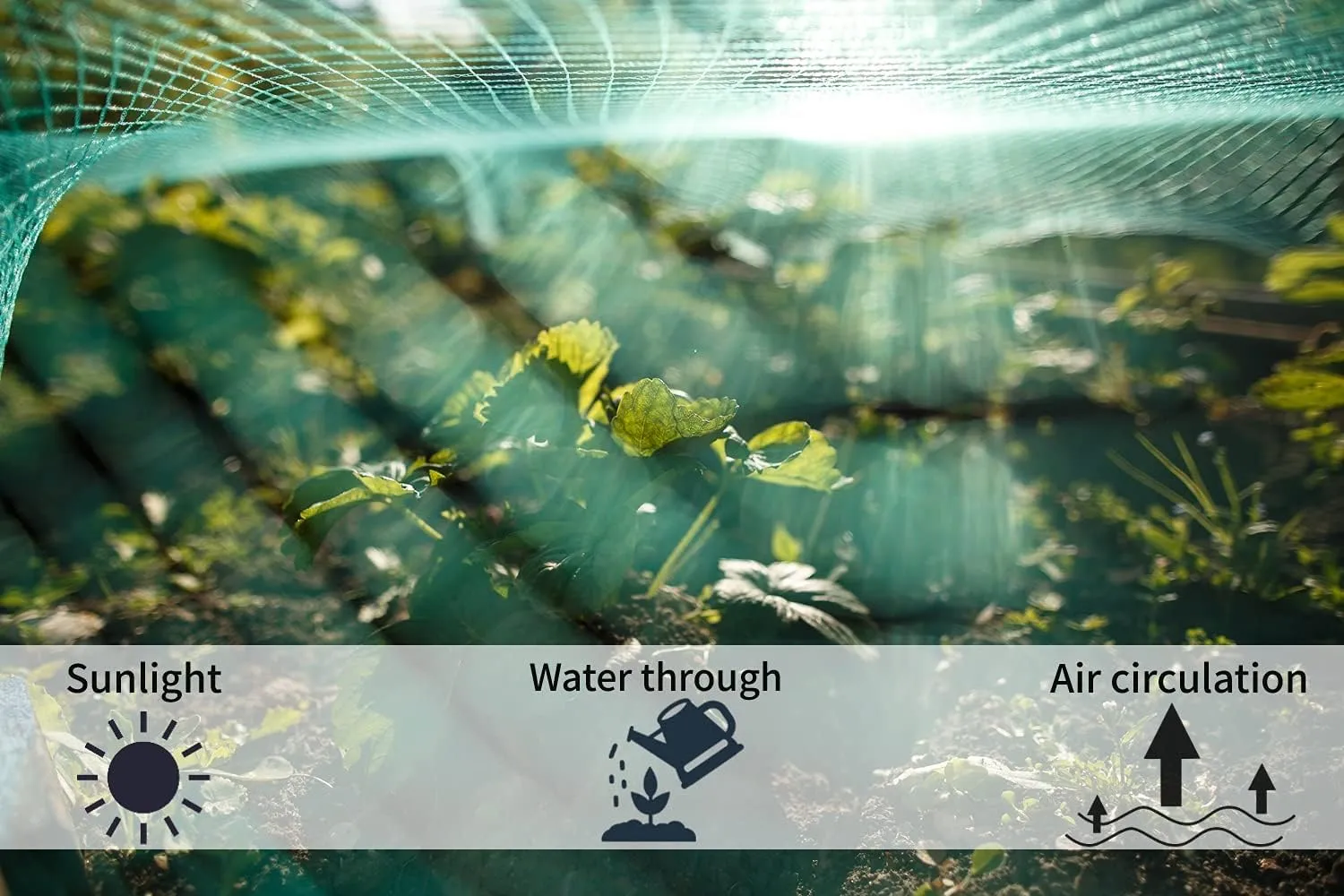

- Agriculture In agricultural applications, mesh screens are used for seed cleaning, grain handling, and pest control, ensuring the health and efficiency of crops.

- Mining and Minerals Processing They are employed in the extraction and processing of various minerals, helping to separate ores from waste materials.

Advantages of Industrial Mesh Screens

The utilization of industrial mesh screens comes with numerous advantages

- Versatility With a wide range of types and materials, industrial mesh screens can be tailored to meet specific needs across various industries.

- Durability Made from robust materials, these screens are designed to withstand harsh environments, ensuring long-term reliability.

- Efficiency Industrial mesh screens enhance operational efficiency by facilitating effective filtration and separation processes.

- Cost-Effectiveness The right mesh screen can improve production efficiency and reduce maintenance costs, making them a valuable investment for businesses.

Conclusion

In summary, industrial mesh screens are indispensable tools across various sectors, supporting a multitude of processes from filtration to construction. Understanding the types, materials, applications, and advantages of these screens can help industries select the right solutions for their specific needs. As technology continues to evolve, industrial mesh screens will likely see further innovations, enhancing their functionality and efficiency even more. Whether in factories, construction sites, or agricultural fields, the importance of industrial mesh screens cannot be overstated.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025