-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Applications and Benefits of Perforated Steel Mesh in Modern Design and Construction

The Advantages and Applications of Perforated Steel Mesh

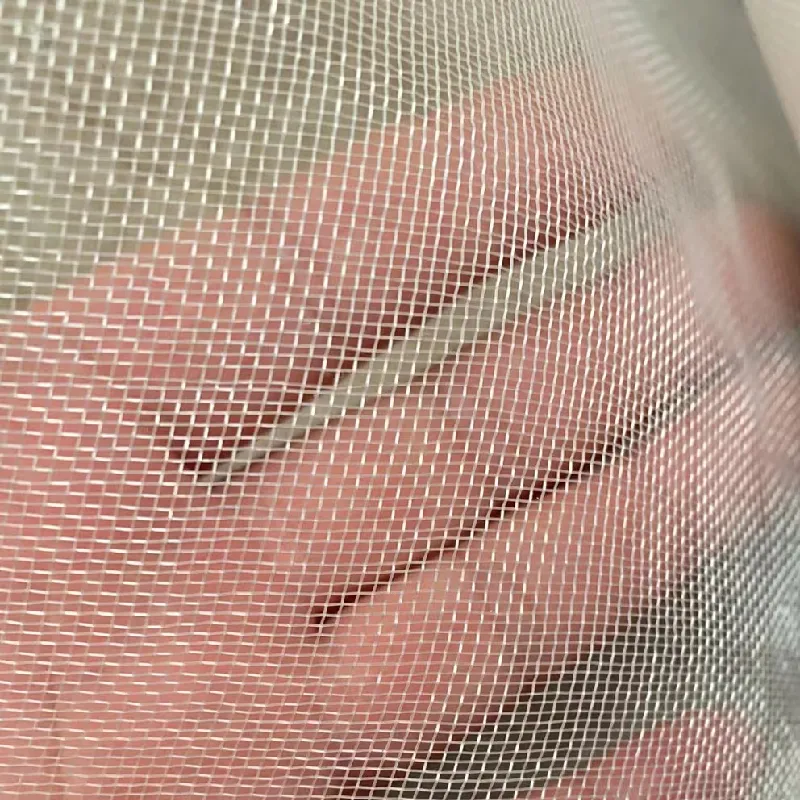

Perforated steel mesh has emerged as a versatile and essential material in various industries due to its unique combination of strength, durability, and aesthetic appeal. Composed of high-quality steel sheets with a series of holes punched through them, perforated steel mesh is available in various patterns, hole sizes, and thicknesses, making it ideal for a wide range of applications.

One of the most significant advantages of perforated steel mesh is its structural integrity. The perforations allow for lighter weight without sacrificing strength, making it an economical choice for construction and architectural projects. When used in building facades, for example, perforated steel can reduce wind load, which is a critical factor in the design of high-rise buildings. Its strength enables it to withstand harsh environmental conditions, providing long-lasting solutions for exterior applications.

Moreover, the aesthetic flexibility of perforated steel mesh cannot be overstated. It offers a modern and sleek look, making it a popular choice among architects and designers. The patterns and designs can be customized to fit the specific vision of a project, allowing for creativity and innovation. This adaptability makes perforated steel mesh a popular choice in the creation of privacy screens, decorative panels, and railings. The interplay of light and shadow through the holes can enhance the architectural beauty of a space, making it both functional and visually appealing.

In addition to its aesthetic properties, perforated steel mesh also serves practical purposes in various industrial applications. In the HVAC industry, it is often used for air filtration, where the mesh allows for the free flow of air while capturing dust and other particles. This application is critical for maintaining air quality in commercial and residential buildings. Furthermore, perforated steel mesh is commonly used in the manufacturing of noise barriers. The perforations help in dissipating sound waves, making it an effective solution for reducing noise pollution in urban areas.

perforated steel mesh

The automotive and aerospace industries also benefit from perforated steel mesh. It is utilized in components that require lightweight yet strong materials, such as heat shields and brackets. The mesh's ability to withstand heat and physical stress makes it a reliable choice for parts subject to extreme conditions. Additionally, the automotive sector employs perforated mesh in grills and bumpers, where it not only provides structural integrity but also enhances the vehicle's design.

Safety is another critical aspect where perforated steel mesh excels. The material can be used in conjunction with safety guards, walkways, and platforms, providing protection without hindering visibility. In industrial settings, it is often integrated into machinery to prevent accidents while allowing for ventilation and cooling.

Sustainability is becoming increasingly important in today's manufacturing processes, and perforated steel mesh is often made from recyclable materials. This aligns with environmental goals and allows industries to promote sustainable practices.

In conclusion, perforated steel mesh is a highly adaptable material that excels in both functional and aesthetic applications. Its strength, light weight, and customizable designs contribute to its popularity across various sectors, from construction and architecture to automotive and industrial manufacturing. As industries continue to innovate, the role of perforated steel mesh is expected to grow, further solidifying its position as an essential material in modern engineering and design.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025