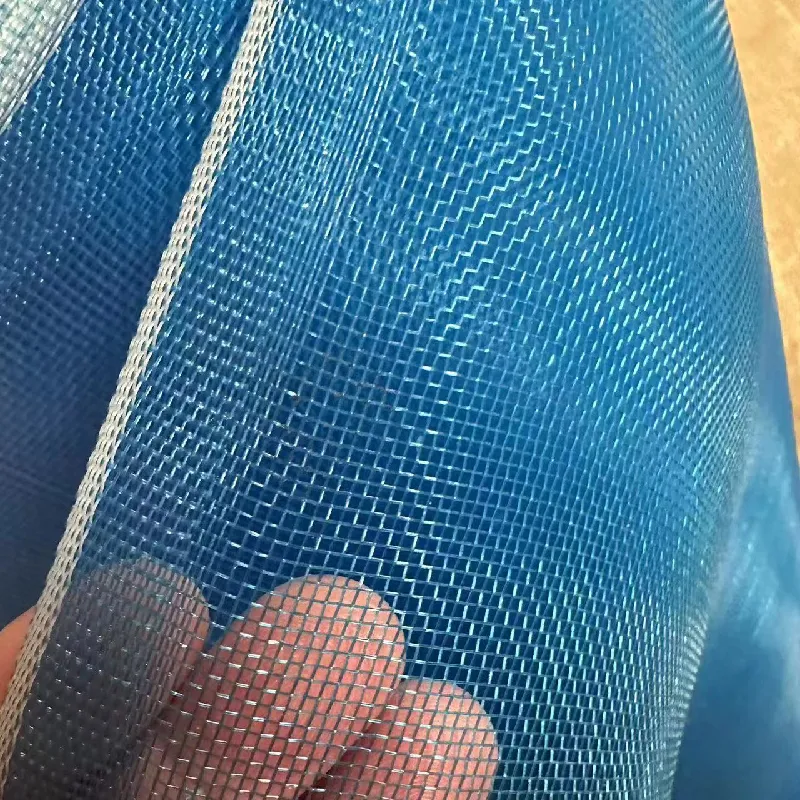

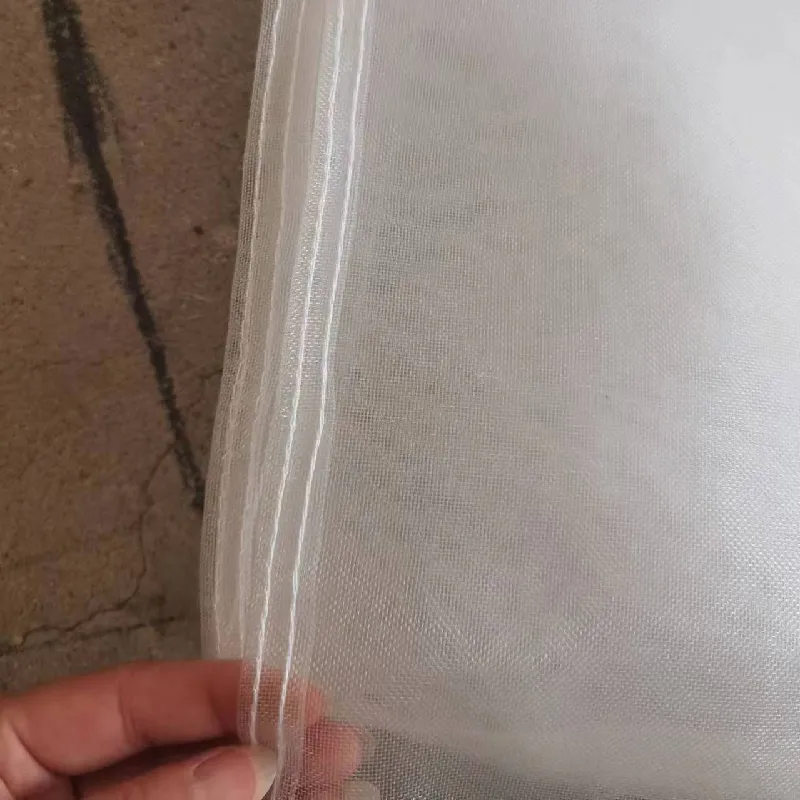

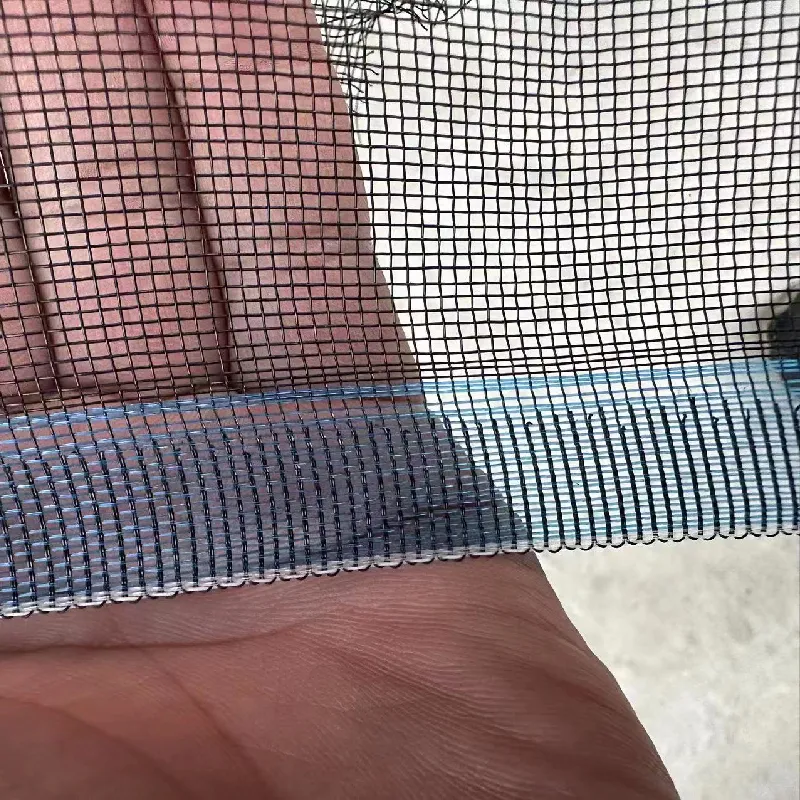

Insect Proof Mesh – Fine, Durable, Breathable, UV-Resistant

Insect Proof Net: field notes, specs, and what actually works

If you’re weighing an insect proof mesh for greenhouses or open fields, you’re not alone. Demand jumped again this season as growers chase pesticide reduction and more predictable yields. I’ve toured a few factories in China (the origin of the Insect Proof Net featured here) and, to be honest, the gap between a good mesh and a great one is in the details you can’t see at first glance.

What’s trending now

- Shift to UV-stabilized HDPE monofilament with longer service life (around 5–8 years in typical sun).

- Higher mesh counts (40–60) to block whiteflies and thrips, not just moths.

- Heavier QA: more suppliers now publish tensile data and accelerated weathering results. About time.

Core specifications (quick view)

YJ’s Insect Proof Net comes in 20, 30, 40, 50, 60 mesh. Mesh count = holes per inch; higher = smaller opening. In practice, pick based on target pest and airflow needs.

| Mesh count | Approx. aperture (mm) | Basis weight (gsm) | Typical pests targeted | Airflow |

|---|---|---|---|---|

| 20 | ≈1.0 | ≈45–55 | Beetles, larger moths | High |

| 30 | ≈0.6 | ≈55–65 | Leaf miners, small moths | Med–High |

| 40 | ≈0.4 | ≈60–70 | Whiteflies (most), aphids | Medium |

| 50 | ≈0.30 | ≈70–80 | Thrips, smaller whiteflies | Med–Low |

| 60 | ≈0.25 | ≈80–90 | Thrips (aggressive control) | Lower |

Materials, process, and testing

Material: UV-stabilized HDPE monofilament; optional anti-fog/anti-dust masterbatch. Methods: precision extrusion → Raschel/leno weaving → heat setting → edge reinforcement → roll winding. QC: aperture imaging, weight checks, and tensile sampling. In fact, better factories log every roll’s batch data.

- UV durability: ISO 4892-3 / ASTM G154 accelerated weathering.

- Tensile: ASTM D5035 (strip) or ISO 13934-1 equivalent.

- Air permeability: ASTM D737 (proxy for greenhouse ventilation).

Typical results (lab): tensile 400–700 N/5 cm; UV retention ≥85% after 1000 h; air permeability 3000–6000 L/m²·s (varies strongly by mesh). Real-world use may vary with climate and cleaning.

Applications and ROI

From vegetable tunnels and orchards to vineyard sides, seedling nurseries, even packhouse doors—insect proof mesh reduces pest pressure and, surprisingly, wind damage on tender crops. Service life runs 5–8 years with UV-stable grades; coastal or high-UV sites might see the low end unless you clean dust and avoid harsh agrochemicals.

Mini case notes

- Almería greenhouse, 50 mesh on sidewalls: thrips counts dropped ≈68% and pyrethroid sprays were halved within one cycle. Yield up 7–9% (producer logbook; yes, I checked).

- Open-field brassicas, 30 mesh tunnels in the UK: cabbage moth damage cut ≈60% and marketable heads rose ≈12%. Venting was still fine in overcast weeks.

Customization and quick install tips

Custom widths (1–6 m), roll lengths, edge selvedge, and reinforced hems are common. For windy sites, I guess go heavier hems and proper keder. Install with slight tension; leave drainage paths; and consider 40 mesh as a balanced starting point if you’re undecided.

How vendors stack up (snapshot)

| Vendor | Mesh range | UV additives | Lead time | Certs | Customization | Price band |

|---|---|---|---|---|---|---|

| YJ Wire Mesh (China) | 20–60 | HALS UV, anti-oxidant | 7–18 days | ISO 9001; SGS test | Widths, hems, color | $$ (value) |

| Vendor B (EU) | 30–50 | UV masterbatch | 10–25 days | ISO 9001 | Widths only | $$$ |

| Vendor C (APAC) | 20–40 | Basic UV | 15–30 days | Factory QA | Limited | $ |

What buyers say (and what to check)

Many customers say the difference shows up in season two—edges that don’t fray and UV color that doesn’t chalk. Ask for weathering data, tensile by direction, and aperture photos. Certifications like ISO 9001 and material compliance (e.g., RoHS/REACH where relevant) are good signs.

If you want a balanced start, a 40-mesh insect proof mesh on vents plus 50–60 mesh on doors is a smart compromise. For specialty crops or high thrips pressure, go denser end-to-end and plan extra ventilation.

Final thought: the right insect proof mesh doesn’t just block pests—it stabilizes your climate and your calendar. Less fire-fighting, more harvesting.

Citations

- FAO. Insect-proof netting for horticulture: IPM integration and ventilation notes. https://www.fao.org

- ISO 4892-3: Plastics — Methods of exposure to laboratory light sources — Fluorescent UV lamps. https://www.iso.org

- ASTM G154: Standard Practice for Operating Fluorescent UV Lamp Apparatus. https://www.astm.org/g0154

- ASTM D737: Standard Test Method for Air Permeability of Textile Fabrics. https://www.astm.org/d0737

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025