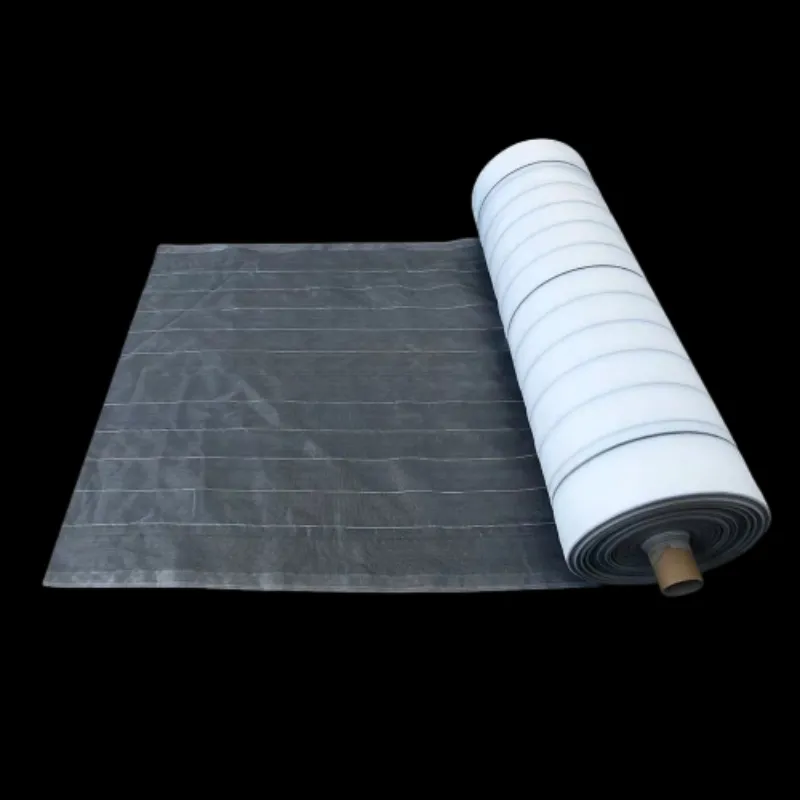

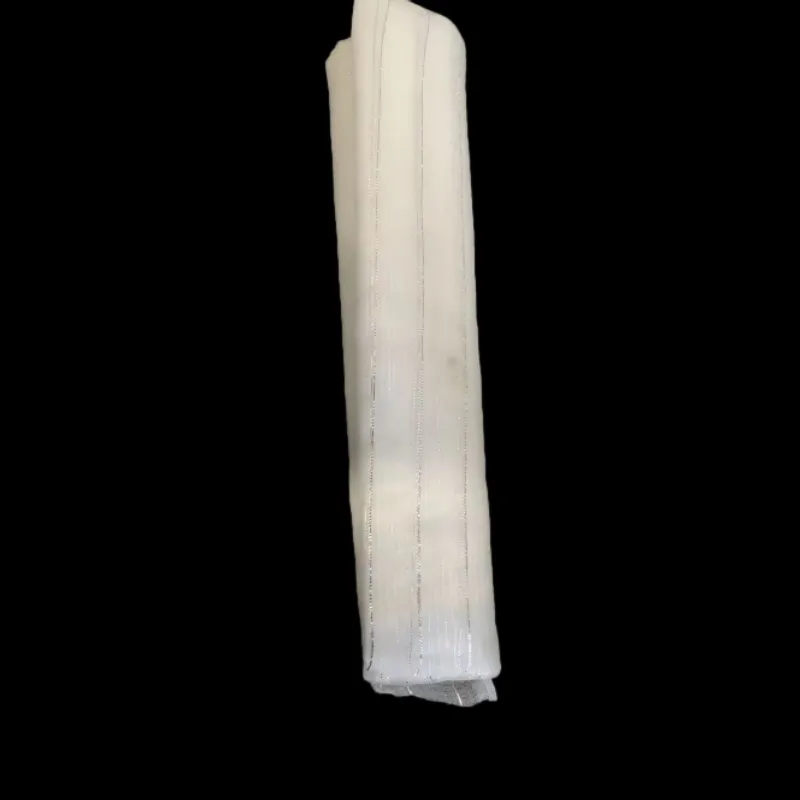

Insect Proof Net: Durable, UV-Resistant, Fine Mesh

Insect Proof Net: field notes, specs, and what growers really ask

If you’ve been following the shift to low-residue farming, you already know why an insect proof net is suddenly the star of the greenhouse. To be honest, I was skeptical a few seasons ago—could a woven fabric really replace a line of sprays? Now, with rising eco-awareness and the real cost of pesticides on health and soil biology, it’s not a fringe topic anymore; it’s the mainstream conversation, especially for high-value crops.

What’s trending in 2025

Across China—the product’s origin—and far beyond, growers are dialing in mesh counts by pest pressure, not guesswork. There’s a quiet shift to UV-stabilized HDPE monofilament, tighter tolerances, and third-party testing. Many customers say the payback is faster than expected because spray intervals stretch out, labor drops, and rejection rates fall. Actually, the biggest surprise is airflow engineering: better ventilation with the same pest exclusion.

Core specifications (typical)

| Material | HDPE monofilament with UV stabilizer (≈2–3%); optional PET/fiberglass |

| Mesh count | 25–60 mesh (typical greenhouse: 40–50 mesh; thrips control: up to 50–60) |

| Aperture size | ≈0.18–0.8 mm (real-world use may vary by tension and framing) |

| Airflow/open area | ≈35–65% open area, engineered for balanced ventilation |

| Weight | 60–120 g/m² |

| Service life | 3–5 seasons outdoors; up to 5+ years under greenhouse UV conditions |

| Color options | Natural, white, black, green; anti-glare finishes upon request |

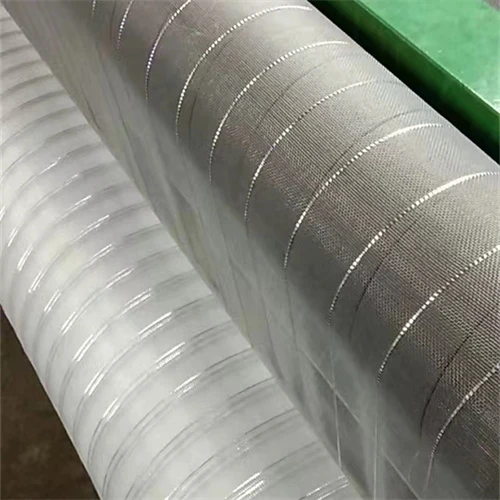

How it’s made (quick process flow)

- Virgin HDPE + UV masterbatch → precision extrusion → monofilament drawing

- Warp knitting/weaving (low defect rate) → heat setting for dimensional stability

- Edge reinforcement (selvage or sewn hem) → roll winding (100–200 m standard)

- QC: mesh/aperture verification, tensile tests, UV-aging simulation, visual inspection

Testing, standards, and real data

Typical lab data we’ve seen: tensile strength 300–550 N/5 cm (ASTM D5035/ISO 13934-1); UV retention ≥85% after 2,000 h (ISO 4892-2, Method A); aperture uniformity ±5%. Chemical safety often aligns with EU REACH and RoHS. For pest exclusion, agronomists map mesh to target: whitefly and aphid control at 40–50 mesh; thrips at 50–60. Certification snapshots: ISO 9001 for QA, SGS reports for material compliance.

Where it’s used and why it works

- Greenhouses, net houses, side vents, roof vents

- Nurseries, orchard bagging, drying racks, post-harvest bays

- Aquaculture intake screens, food plants, warehouse dock doors

Advantages: fewer pesticide applications, steadier microclimate, cleaner fruit finish, and better worker safety. Many growers mention quieter nights—less spraying stress, literally.

Vendor snapshot (real-world differences)

| Vendor | Mesh range | UV package | Lead time | Certs |

|---|---|---|---|---|

| YJ Wire Mesh (China) | 25–60 | 2–3% UV, hot-climate grade | 10–20 days (≈) | ISO 9001, SGS material |

| EU Brand B | 30–50 | Premium UV; cooler climates | 3–5 weeks | REACH, RoHS |

| Local Importer C | 20–40 | Basic UV | Stock-dependent | Vary by batch |

Customization that matters

Custom widths (1–6 m), hemmed edges, zipper doors, flame-retardant additives, and pre-cut vent panels. For high thrips zones, specify tighter mesh and verify aperture by lab report—small detail, big outcome. Yes, insect proof net choices should match your pest map.

Case notes from the field

- Yunnan greenhouse peppers: 50-mesh insect proof net cut whitefly counts by ≈70% and reduced insecticide sprays by 40% in the first season.

- Almería tomato tunnels: airflow-optimized 40-mesh kept aphids in check; grade-out improved by 8–12% (reported by packhouse QA).

What buyers keep asking

Does it pay off? Usually yes—when framing is sealed and vents are covered correctly. How long does it last? With UV-stable HDPE, 3–5 seasons is normal. Any certifications? Look for ISO 9001, REACH/RoHS statements, and test methods like ISO 4892-2 and ASTM D5035 on the report. And remember, a insect proof net doesn’t replace IPM—it strengthens it.

References

- ISO 4892-2: Plastics—Methods of exposure to laboratory light sources—Xenon-arc.

- ASTM D5035 / ISO 13934-1: Textile tensile properties (strip/grab methods).

- FAO: Integrated Pest Management guidelines and case studies on physical exclusion.

- EU REACH Regulation (EC) No 1907/2006; RoHS Directive 2011/65/EU.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025