-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Leading Manufacturer of Advanced Wire Mesh Welding Machines for Various Industrial Applications

The Rise of Wire Mesh Welding Machine Manufacturers

In the contemporary industrial landscape, the demand for high-quality wire mesh has surged, driven by construction, automotive, and manufacturing sectors. This rise has given birth to a burgeoning market for wire mesh welding machines, with numerous manufacturers vying for attention. These machines are pivotal in producing wire mesh products that meet the strict standards required for diverse applications.

Wire mesh welding machines primarily serve the purpose of fabricating various types of wire mesh, including chain-link fences, concrete reinforcement, and security mesh. The machines work by automatically welding intersecting wires together, ensuring consistency and precision that manual methods cannot achieve. As the demand for such products grows, so does the need for innovative welding machine manufacturers.

The evolution of technology in wire mesh welding has led manufacturers to invest in advanced machinery that enhances efficiency. Modern machines utilize automated systems, enabling high-speed production with minimal operator intervention. This automation not only accelerates production rates but also reduces the likelihood of errors, thereby increasing overall product quality.

Moreover, manufacturers now offer a range of customization options, allowing clients to specify dimensions, wire gauges, and welding patterns according to their needs. This flexibility is a response to the diverse demands of different industries which require specific wire mesh qualities. For instance, the construction industry may require robust, tightly spaced meshes for concrete reinforcement, while agricultural applications might call for lighter, more flexible designs.

wire mesh welding machine manufacturer

Another significant trend among wire mesh welding machine manufacturers is the focus on sustainability. In an era where environmental considerations are paramount, many manufacturers are adapting their equipment to minimize waste and enhance energy efficiency. Utilizing energy-efficient motors and implementing recycling processes for metal offcuts are just some of the practices being adopted to reduce the environmental impact of production.

As competition intensifies in the market, manufacturers are also stepping up their after-sales support and service offerings. Providing comprehensive training for machine operators and ensuring efficient maintenance are essential strategies to foster long-term customer relationships. An effective after-sales service not only enhances customer satisfaction but also solidifies a manufacturer’s reputation in the industry.

Furthermore, global supply chains and the rapid dissemination of information have led to increased collaboration among manufacturers. Partnerships across borders allow for the sharing of knowledge, technology, and best practices, which can drive innovation and improve product offerings. This interconnectedness is vital as manufacturers strive to remain competitive in a fast-evolving market.

It is also essential to highlight the role of certification and quality assurance in the wire mesh welding machine manufacturing sector. With safety and performance standards becoming more stringent, manufacturers are compelled to adhere to international standards such as ISO and CE certifications. These certifications not only ensure product quality but also provide clients with added assurance regarding the reliability and safety of the machines they purchase.

In conclusion, the landscape for wire mesh welding machine manufacturers is marked by technological advancements, a commitment to sustainability, and a focus on customer satisfaction. As industries continue to evolve and demand high-quality wire mesh products, the role of these manufacturers will undoubtedly become more prominent. With a blend of innovation, quality assurance, and responsive customer service, wire mesh welding machine manufacturers are poised for growth in the years to come, solidifying their importance in the broader manufacturing ecosystem.

-

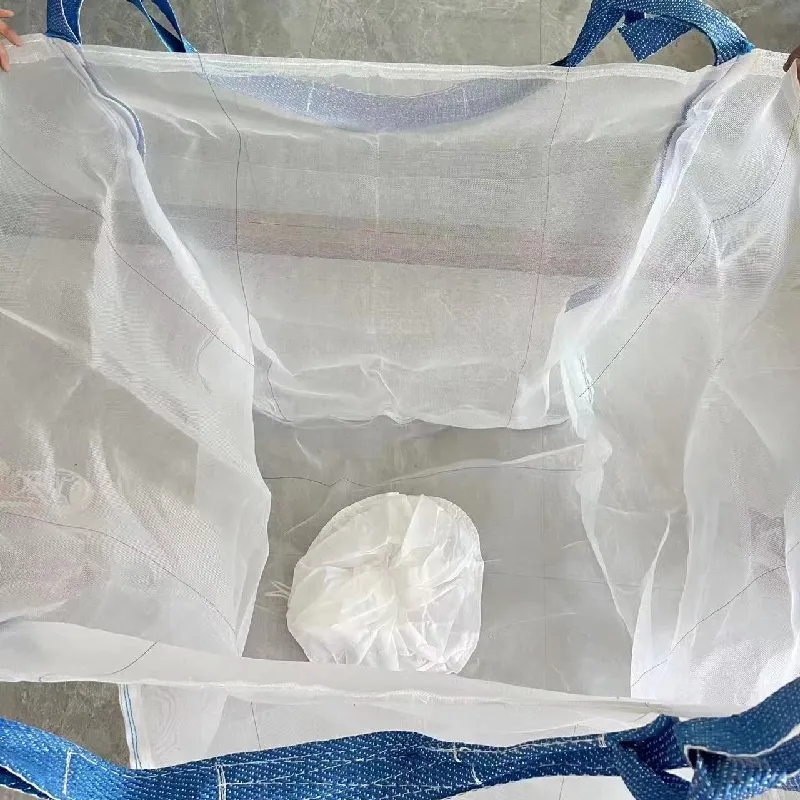

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025