-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 20, 2025 02:55

Back to list

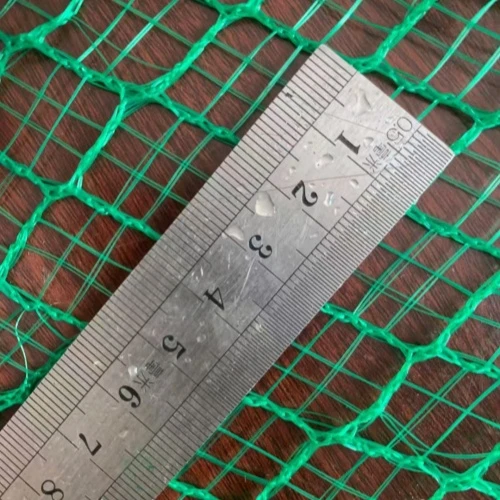

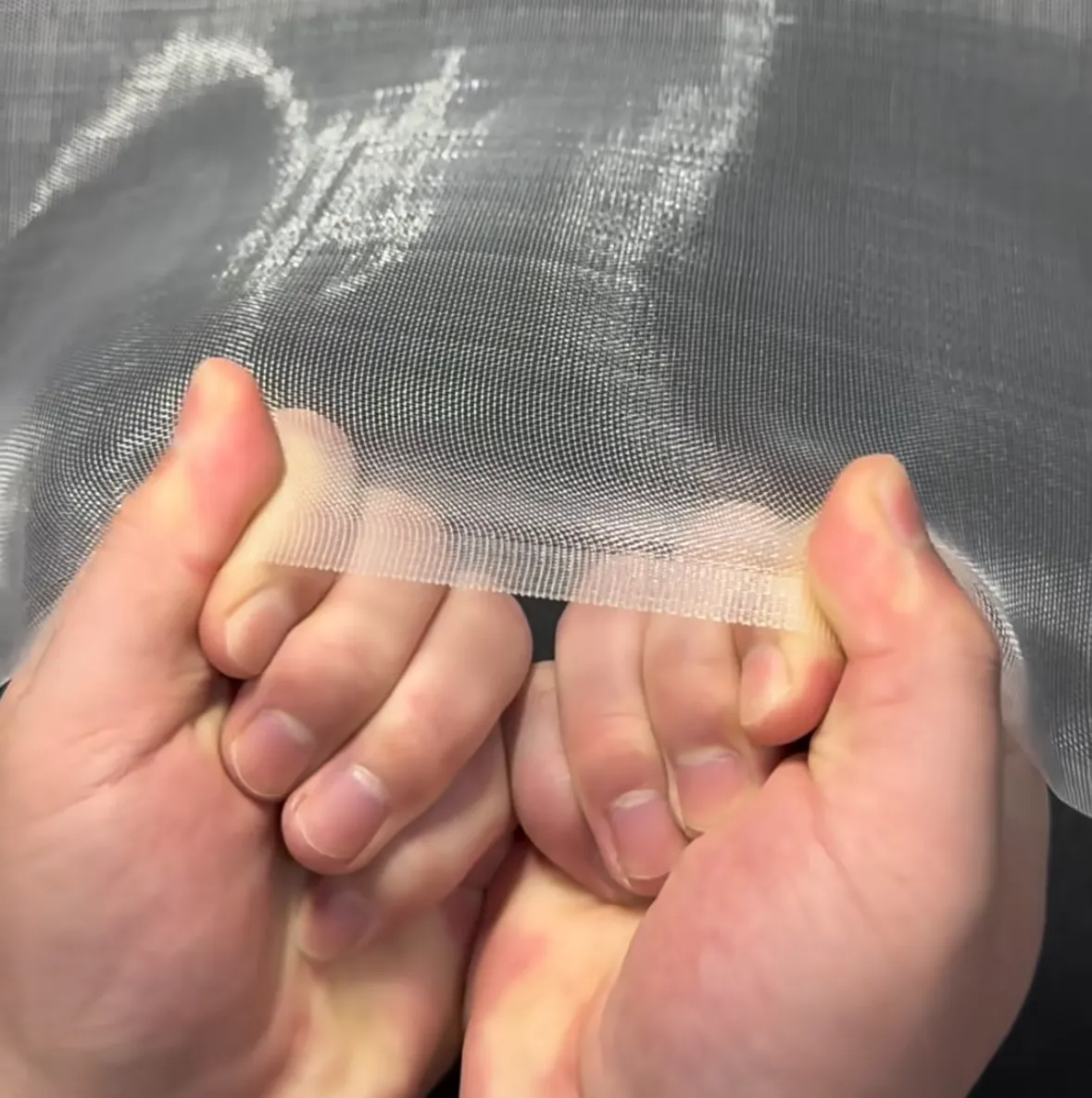

mesh manufacturing

In today's rapidly evolving manufacturing landscape, mesh manufacturing is at the forefront of innovation, offering unique solutions that enhance product development and production processes. This transformative technology is not simply a buzzword but a substantive advancement that leverages complex algorithms and state-of-the-art machinery to create intricate meshes used across various industries, including medical devices, aerospace, and consumer electronics.

Mesh manufacturing additionally champions sustainability, a growing concern across industries aiming to reduce their environmental footprint. By optimizing material usage and embracing innovative recycling techniques, companies specializing in mesh production contribute to more sustainable manufacturing practices. Efficient resource management and waste reduction are integral components of the environmental ethos adopted within the mesh manufacturing sector. Furthermore, expertise in mesh manufacturing is evidenced by an in-depth understanding of the material sciences behind the products. Experts in the field possess the unique ability to tailor the manufacturing process to best suit the material being used, whether it be metals, plastics, or composite materials. These experts rely on analytical tools to forecast material behavior, ensuring that each mesh structure meets or exceeds the performance criteria essential for its intended use. In aerospace, for instance, mesh manufacturing significantly reduces aircraft weight, which improves fuel efficiency and decreases emissions. The application of advanced meshes in aircraft design showcases the transformative power of this technology, leading to the development of lighter components without compromising structural integrity. In doing so, mesh manufacturing contributes to the evolution of cleaner and more efficient air travel. Consumer electronics also benefit from mesh technology, particularly in the development of flexible electronic components. The adaptability of mesh materials allows manufacturers to create devices that are both robust and lightweight, enhancing user experience while maintaining product integrity. Mesh structures enable the design of innovative features such as foldable screens and conductive textiles, propelling the next generation of electronic devices. In conclusion, mesh manufacturing represents a pivotal leap forward that provides a multitude of enhancements to traditional manufacturing processes. By incorporating experience, expertise, authoritativeness, and trustworthiness, mesh manufacturing not only revolutionizes product design and quality but also champions sustainability and efficiency across industries. Its versatility ensures that products are crafted to the highest standards, meeting the evolving demands of an ever-expanding marketplace and setting a precedent for future manufacturing innovations.

Mesh manufacturing additionally champions sustainability, a growing concern across industries aiming to reduce their environmental footprint. By optimizing material usage and embracing innovative recycling techniques, companies specializing in mesh production contribute to more sustainable manufacturing practices. Efficient resource management and waste reduction are integral components of the environmental ethos adopted within the mesh manufacturing sector. Furthermore, expertise in mesh manufacturing is evidenced by an in-depth understanding of the material sciences behind the products. Experts in the field possess the unique ability to tailor the manufacturing process to best suit the material being used, whether it be metals, plastics, or composite materials. These experts rely on analytical tools to forecast material behavior, ensuring that each mesh structure meets or exceeds the performance criteria essential for its intended use. In aerospace, for instance, mesh manufacturing significantly reduces aircraft weight, which improves fuel efficiency and decreases emissions. The application of advanced meshes in aircraft design showcases the transformative power of this technology, leading to the development of lighter components without compromising structural integrity. In doing so, mesh manufacturing contributes to the evolution of cleaner and more efficient air travel. Consumer electronics also benefit from mesh technology, particularly in the development of flexible electronic components. The adaptability of mesh materials allows manufacturers to create devices that are both robust and lightweight, enhancing user experience while maintaining product integrity. Mesh structures enable the design of innovative features such as foldable screens and conductive textiles, propelling the next generation of electronic devices. In conclusion, mesh manufacturing represents a pivotal leap forward that provides a multitude of enhancements to traditional manufacturing processes. By incorporating experience, expertise, authoritativeness, and trustworthiness, mesh manufacturing not only revolutionizes product design and quality but also champions sustainability and efficiency across industries. Its versatility ensures that products are crafted to the highest standards, meeting the evolving demands of an ever-expanding marketplace and setting a precedent for future manufacturing innovations.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025