-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 25, 2025 20:47

Back to list

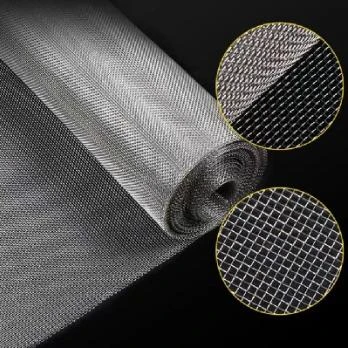

mesh manufacturing machine

The advancement of technology in the 21st century has propelled various manufacturing processes into an era of innovation and efficiency. Among these groundbreaking developments is the mesh manufacturing machine, a game-changer in producing mesh materials for diverse industries. These machines are engineered to cater to the demanding needs of sectors such as healthcare, construction, and even aerospace, emphasizing precision, durability, and speed.

Authoritative Insights Industry leaders acknowledge mesh manufacturing machines as indispensable tools in the push towards sustainable production methods. Their ability to produce strong and lightweight mesh materials is pivotal in sectors aiming to reduce environmental impact. For instance, in aerospace, the use of mesh components improves fuel efficiency due to their lightweight yet durable nature. For healthcare, the production of precise and sterile meshes meets the rigorous standards required for medical applications. These machines stand as testament to the innovative spirit driving the manufacturing industry toward a more sustainable future. Trustworthy Quality The reliability of mesh manufacturing machines is underscored through rigorous testing and accreditation by international bodies. Companies that manufacture these machines are committed to upholding the highest standards, evidenced by certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. Users trust that each machine undergoes thorough validation, ensuring that every mesh produced meets the specifications and regulatory standards set by their respective industries. This commitment to quality has established these machines as reputable assets in any production line. In conclusion, the mesh manufacturing machine is not merely a technological tool but a comprehensive solution to modern manufacturing challenges. Its practical applications across various industries, backed by expert engineering and rigorous certifications, affirm its place as a cornerstone of innovation. As demand for sustainable and efficient manufacturing processes continues to rise, businesses equipped with these machines will undoubtedly lead the charge, setting benchmarks for quality, precision, and environmental stewardship.

Authoritative Insights Industry leaders acknowledge mesh manufacturing machines as indispensable tools in the push towards sustainable production methods. Their ability to produce strong and lightweight mesh materials is pivotal in sectors aiming to reduce environmental impact. For instance, in aerospace, the use of mesh components improves fuel efficiency due to their lightweight yet durable nature. For healthcare, the production of precise and sterile meshes meets the rigorous standards required for medical applications. These machines stand as testament to the innovative spirit driving the manufacturing industry toward a more sustainable future. Trustworthy Quality The reliability of mesh manufacturing machines is underscored through rigorous testing and accreditation by international bodies. Companies that manufacture these machines are committed to upholding the highest standards, evidenced by certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. Users trust that each machine undergoes thorough validation, ensuring that every mesh produced meets the specifications and regulatory standards set by their respective industries. This commitment to quality has established these machines as reputable assets in any production line. In conclusion, the mesh manufacturing machine is not merely a technological tool but a comprehensive solution to modern manufacturing challenges. Its practical applications across various industries, backed by expert engineering and rigorous certifications, affirm its place as a cornerstone of innovation. As demand for sustainable and efficient manufacturing processes continues to rise, businesses equipped with these machines will undoubtedly lead the charge, setting benchmarks for quality, precision, and environmental stewardship.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025