-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

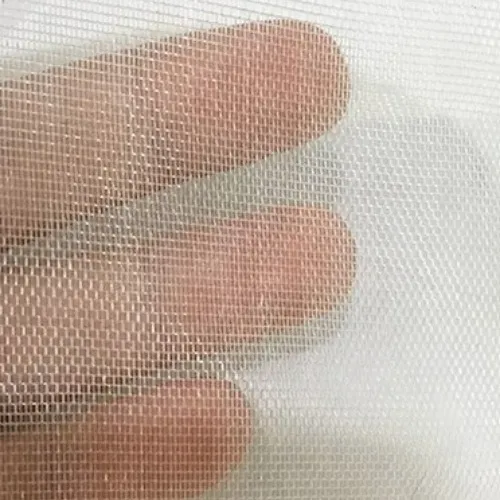

metal steel mesh

The Versatility of Metal Steel Mesh in Modern Applications

Metal steel mesh, a crucial material in various industries, boasts a unique combination of strength, durability, and versatility. Composed primarily of steel, this mesh is engineered to serve multiple functions across different sectors, ranging from construction to manufacturing and even aesthetics. Understanding its properties and applications can shed light on its importance in contemporary technology and infrastructure.

Composition and Types of Metal Steel Mesh

Metal steel mesh is produced by weaving or welding steel wires together, forming a grid-like structure. This grid can vary in terms of wire diameter, mesh spacing, and coating, which can include galvanization for corrosion resistance. There are two main types of metal steel mesh welded mesh and woven mesh.

1. Welded Mesh This type is created by welding intersecting wires at their joints, providing superior strength and stability. It is often used in construction for reinforcing concrete structures, such as slabs, walls, and foundations.

2. Woven Mesh Produced by interlacing wires, woven mesh offers flexibility and adaptability. It is commonly used in applications requiring filtrations, such as sieves and strainers, or for protective barriers in various settings.

Construction Industry Applications

In the realm of construction, metal steel mesh plays an indispensable role. Its primary function is to reinforce concrete, enhancing its tensile strength and structural integrity. When embedded in concrete, steel mesh prevents cracking and shifting, ensuring longevity. Additionally, metal steel mesh is often employed in wall partitions, fencing, and safety barriers, providing both security and visibility.

Furthermore, architectural designs have embraced metal steel mesh for aesthetic elements. It can be shaped into decorative panels, facades, or canopies, adding a contemporary touch to buildings. The mesh’s ability to allow light and airflow while maintaining structural stability makes it an attractive choice for innovative design.

metal steel mesh

Industrial Uses

Beyond construction, metal steel mesh finds extensive use in various industrial applications. In manufacturing, it is used in the production of various machinery parts, filters, and sieves. Its robustness ensures that it can withstand harsh conditions, making it ideal for heavy-duty applications.

In the agricultural sector, metal steel mesh is employed in the fabrication of cages and enclosures. It provides shelter for livestock while ensuring proper ventilation. Additionally, its use in soil stabilization techniques aids in preventing erosion, safeguarding crops and landscapes.

Environmental Considerations

The environmental impact of metal steel mesh is noteworthy. Steel is recyclable, making it a sustainable material choice for modern applications. The durability of metal steel mesh means that its life cycle can extend significantly, reducing the need for frequent replacements and thereby lessening waste generation.

Conclusion

The significance of metal steel mesh extends far beyond its basic physical properties. As a versatile material, it seamlessly integrates into various industries, fulfilling diverse functions that enhance safety, utility, and aesthetic appeal. Whether reinforcing concrete in towering skyscrapers, filtering substances in industrial processes, or serving as a decorative element in architecture, metal steel mesh proves to be an invaluable asset in today’s world.

As technology continues to advance, so too will the applications of metal steel mesh, potentially leading to new innovations in design and functionality. The ongoing evolution in materials science may further enhance its qualities, ensuring that metal steel mesh remains a cornerstone of modern manufacturing and construction for years to come. Its contributions to sustainability, safety, and design ingenuity make it a material worthy of recognition and appreciation in the contemporary landscape.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025