-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 20, 2025 04:35

Back to list

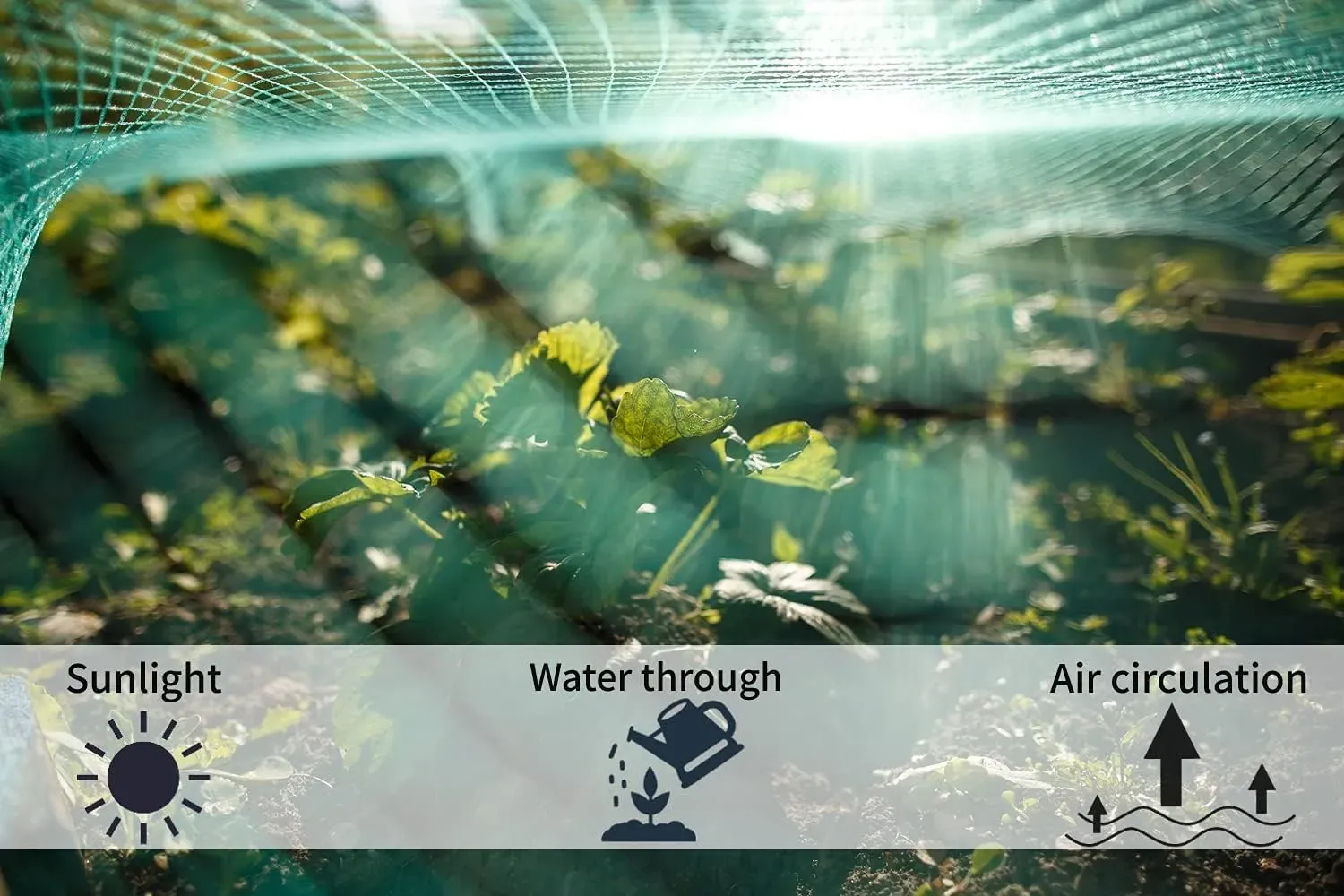

bird mesh

In today's fast-evolving industrial sector, metal steel mesh stands out as a crucial component, not just for its robust multifaceted applications but for its esteemed reliability in critical infrastructures. As businesses and industries continuously expand their operations, the necessity for durable and flexible materials like metal steel mesh becomes ever more apparent. This article delves into the experiential, expert-driven, authoritative, and trustworthy nature of metal steel mesh, focusing on its application, strengths, and benefits.

Authority in the metal steel mesh market is bolstered by continuous advancements in metallurgical research. Research institutions and industry leaders are committed to developing new alloys and coating techniques that enhance the mesh's performance in aggressive environments, such as those involving high temperatures and corrosive elements. These innovations position metal steel mesh at the forefront of material science, providing unparalleled safety and efficiency in challenging applications. Trustworthiness is a cornerstone characteristic of metal steel mesh, backed by rigorous testing and certification. Compliance with international standards, such as ISO and ASTM, guarantees that users receive a product capable of performing under the toughest conditions. Testimonials and case studies from high-profile projects—ranging from skyscrapers to bridges—underscore the mesh's unmatched reliability. In these reports, engineers note the metal steel mesh's extraordinary resilience and its role in extending the lifespan of critical structures. In conclusion, metal steel mesh epitomizes the blend of innovation and reliability. Its widespread adoption across various industries underscores its advantage as a versatile, durable, and efficient material. With advancements in manufacturing and a robust track record of performance, metal steel mesh remains the material of choice for professionals seeking solutions that meet both modern aesthetic and stringent safety standards. Whether it's reinforcing a skyscraper or securing an industrial facility, metal steel mesh proves to be an invaluable asset, offering the ideal balance of strength, flexibility, and dependability.

Authority in the metal steel mesh market is bolstered by continuous advancements in metallurgical research. Research institutions and industry leaders are committed to developing new alloys and coating techniques that enhance the mesh's performance in aggressive environments, such as those involving high temperatures and corrosive elements. These innovations position metal steel mesh at the forefront of material science, providing unparalleled safety and efficiency in challenging applications. Trustworthiness is a cornerstone characteristic of metal steel mesh, backed by rigorous testing and certification. Compliance with international standards, such as ISO and ASTM, guarantees that users receive a product capable of performing under the toughest conditions. Testimonials and case studies from high-profile projects—ranging from skyscrapers to bridges—underscore the mesh's unmatched reliability. In these reports, engineers note the metal steel mesh's extraordinary resilience and its role in extending the lifespan of critical structures. In conclusion, metal steel mesh epitomizes the blend of innovation and reliability. Its widespread adoption across various industries underscores its advantage as a versatile, durable, and efficient material. With advancements in manufacturing and a robust track record of performance, metal steel mesh remains the material of choice for professionals seeking solutions that meet both modern aesthetic and stringent safety standards. Whether it's reinforcing a skyscraper or securing an industrial facility, metal steel mesh proves to be an invaluable asset, offering the ideal balance of strength, flexibility, and dependability.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025