-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 20, 2025 05:36

Back to list

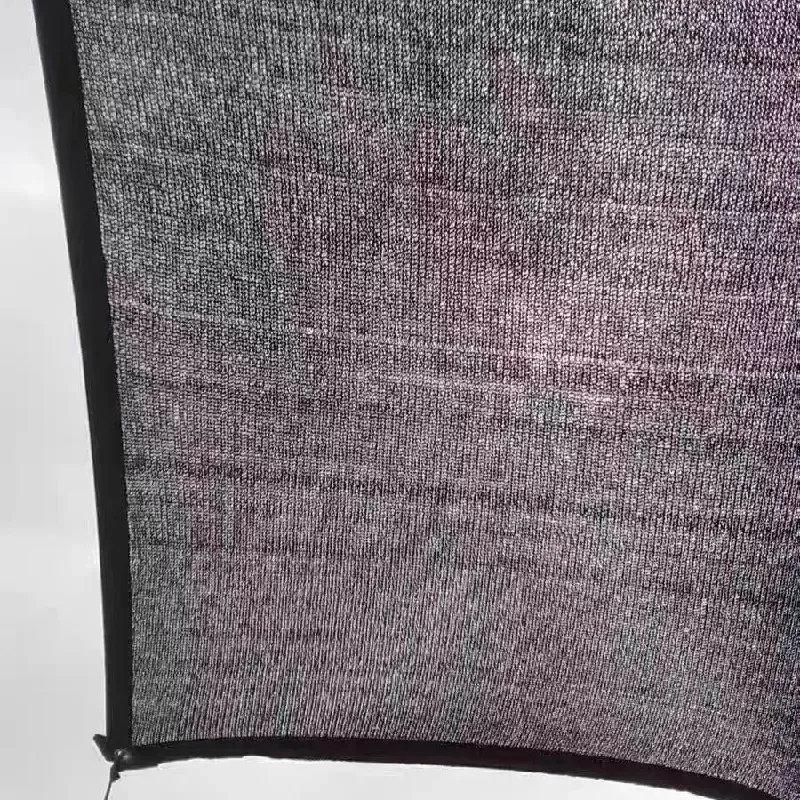

welded wire mesh

Mild steel welded wire mesh stands out as a versatile and reliable product in the engineering and construction industries. A product defined by its durability and adaptability, it has become a staple for various applications such as fencing, reinforcement, and even in creative artistic endeavors. The cornerstone of its popularity lies in its combination of high tensile strength, malleability, and cost-effectiveness.

Regarding authoritativeness, mild steel welded wire mesh commands respect amongst industry giants due to its extensive usage and proven track record. It has been pivotal in meeting rigorous standards set by regulatory bodies across the globe. For example, in urban infrastructure developments, using this material aligns with required safety protocols while also offering economic advantages. Its widespread acceptance and validation by engineering authorities consolidate its standing as an authoritative construction material. Lastly, the trustworthiness of mild steel welded wire mesh is reinforced by its continued performance and reliability. Over decades, it has gained the trust of users, builders, and inspectors alike. This trustworthiness is not just a function of its physical properties, but also of the transparent manufacturing processes and quality checks that it undergoes. Manufacturers often provide comprehensive specifications and certifications, allowing consumers to make informed decisions, thereby reinforcing consumer confidence. In conclusion, mild steel welded wire mesh rises above as a product that merges practical experience, technical expertise, authoritative industry endorsement, and proven trustworthiness. Its adaptability across multiple applications, from industrial to decorative, underscores its indispensable nature in modern construction and design landscapes. With evolving innovations and a focus on sustainability, mild steel welded wire mesh will likely retain its relevance and continue to deliver exceptional value for construction needs around the globe.

Regarding authoritativeness, mild steel welded wire mesh commands respect amongst industry giants due to its extensive usage and proven track record. It has been pivotal in meeting rigorous standards set by regulatory bodies across the globe. For example, in urban infrastructure developments, using this material aligns with required safety protocols while also offering economic advantages. Its widespread acceptance and validation by engineering authorities consolidate its standing as an authoritative construction material. Lastly, the trustworthiness of mild steel welded wire mesh is reinforced by its continued performance and reliability. Over decades, it has gained the trust of users, builders, and inspectors alike. This trustworthiness is not just a function of its physical properties, but also of the transparent manufacturing processes and quality checks that it undergoes. Manufacturers often provide comprehensive specifications and certifications, allowing consumers to make informed decisions, thereby reinforcing consumer confidence. In conclusion, mild steel welded wire mesh rises above as a product that merges practical experience, technical expertise, authoritative industry endorsement, and proven trustworthiness. Its adaptability across multiple applications, from industrial to decorative, underscores its indispensable nature in modern construction and design landscapes. With evolving innovations and a focus on sustainability, mild steel welded wire mesh will likely retain its relevance and continue to deliver exceptional value for construction needs around the globe.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025