Need Humane, Durable Bird Netting to Protect Your Property?

Knotted PE/Nylon Agriculture Anti Bird Netting: Field Notes, Specs, and What Actually Works

If you’ve walked a vineyard at dawn or checked a blueberry tunnel after a week of storms, you know the stakes. That’s why many growers are turning to bird netting that doesn’t give up mid-season. I’ve tested and seen a lot of meshes over the years; some fray, some sag, and some—surprisingly—just quietly do the job.

Industry trend check

Two big shifts stand out: UV-stabilized HDPE (less weight, better weathering) replacing heavier nylon in open fields, and a move from purely knotted to knotless Raschel for softer handling on delicate fruit. Sustainability matters too—recyclable polymers and longer service life are becoming purchasing criteria, not nice-to-haves.

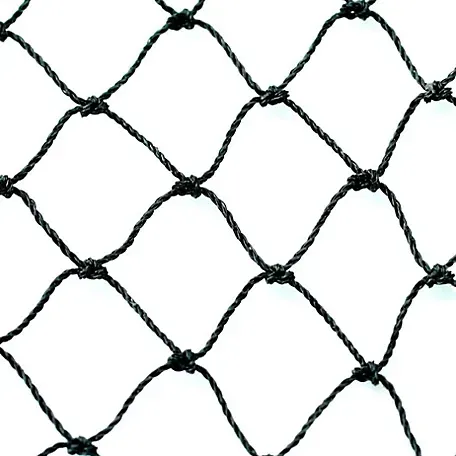

What this product is

Knotted PE/Nylon/Plastic Agriculture Anti Bird Netting from China uses UV-resistant polyethylene with optional nylon variants. It’s designed for sun, wind, winter rain—the whole calendar. Customers tell me installation is straightforward; the key is edge reinforcement and tensioning, which many overlook.

| Parameter | Typical value | Notes (real-world may vary) |

|---|---|---|

| Polymer | HDPE / Nylon 6 | UV-stabilized |

| Construction | Knotted or Knotless Raschel | Choose by crop/contact |

| Filament Ø | ≈0.18–0.50 mm | Thicker = higher tensile |

| Mesh size | 15–60 mm | Small birds vs. airflow |

| Mass (GSM) | ≈25–60 g/m² | Weight affects sag |

| Tensile (strand) | ≥150 N (ISO 1806) | Lab tested |

| UV package | 2–3% HALS + carbon black | ASTM G154/ISO 4892 |

| Width × Length | Up to 12 m × 200 m | Custom on request |

| Service life | 5–8 years | UV index and care dependent |

| Certifications | ISO 9001, REACH/RoHS | Material compliance |

Process flow (how it’s made)

- Resin selection: HDPE or Nylon 6 + UV masterbatch.

- Monofilament extrusion and drawing for strength.

- Knotting or Raschel knitting, then heat-setting to stabilize mesh.

- Edge selvedge reinforcement and dimensional inspection.

- Testing: mesh breaking force (ISO 1806), UV aging (ASTM G154/ISO 4892), dimensional stability, elongation.

Where it’s used

- Vineyards, berry farms, orchards, vegetable tunnels. - Aquaculture pens (predator deterrence). - Warehouses and eaves. - Facades and parking canopies. - Airport perimeters (as part of wildlife risk plans). With bird netting, installation detail matters: cable spacing around 3–5 m, proper corner anchoring, and tensioners save headaches.

Advantages I’ve noticed

- High tensile for the weight; less sag after storms.

- Low glare black nets reduce bird pressure (anecdotal but common).

- Knotless options are kinder to soft fruit and pickers’ hands.

Mini case notes

Vineyard, NZ: 30 mm knotless HDPE over 18 ha reduced peck loss from ~12% to 2.1% in year one; post-season tensile retention ~88% after 1000 h UV lab cycle. Berry farm, Spain: Knotted 20 mm with reinforced edges cut bird ingress to near-zero; crews liked the tougher selvedge for clips.

Vendor snapshot (indicative)

| Vendor | Strength | Lead time | Certs | Price |

|---|---|---|---|---|

| YJ Wire Mesh (China) | Knotted & knotless, OEM sizes | 10–25 days | ISO 9001, REACH/RoHS | $ |

| EU Brand A | Premium Raschel | 3–5 weeks | ISO 14001 | $$–$$$ |

| NA Distributor B | Stock HDPE rolls | 2–7 days | SGS UV tests | $$ |

| Local Fabricator | Install + custom edges | 1–3 weeks | Contractor licenses | $$–$$$ |

Customization tips

Specify mesh size by target species; ask for heat-set nets for windier sites; consider black color for UV longevity; request edge rope or sewn tape where clips are frequent. For bird netting over long spans, plan for maintenance walkways—future you will be grateful.

Customer feedback: “We expected 3–4 seasons; going into year 6 with minor repairs,” says a Midwest cherry grower. Not scientific, but it aligns with lab retention numbers I’ve seen.

Standards and testing

Look for ISO 1806 mesh breaking force reports and UV aging per ASTM G154 or ISO 4892. Compliance with REACH/RoHS is a plus if your buyer audits materials. Typical spec targets: ≥85% tensile retention after 1000 h UV; elongation at break 12–22% (strand), dimensional change ≤3% after heat-set.

Bottom line

Choose bird netting by species pressure, wind load, labor handling, and UV index. The right mesh pays back fast—usually in one harvest cycle—then quietly keeps paying.

- ISO 1806: Fishing nets — Determination of mesh breaking force of netting. https://www.iso.org/standard/64240.html

- ASTM G154: UV Exposure of Nonmetallic Materials. https://www.astm.org/g0154-22.html

- ISO 4892-2: Plastics — Methods of exposure to laboratory light sources. https://www.iso.org/standard/72238.html

- FAA AC 150/5200-33C: Hazardous Wildlife Attractants On or Near Airports. https://www.faa.gov

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025