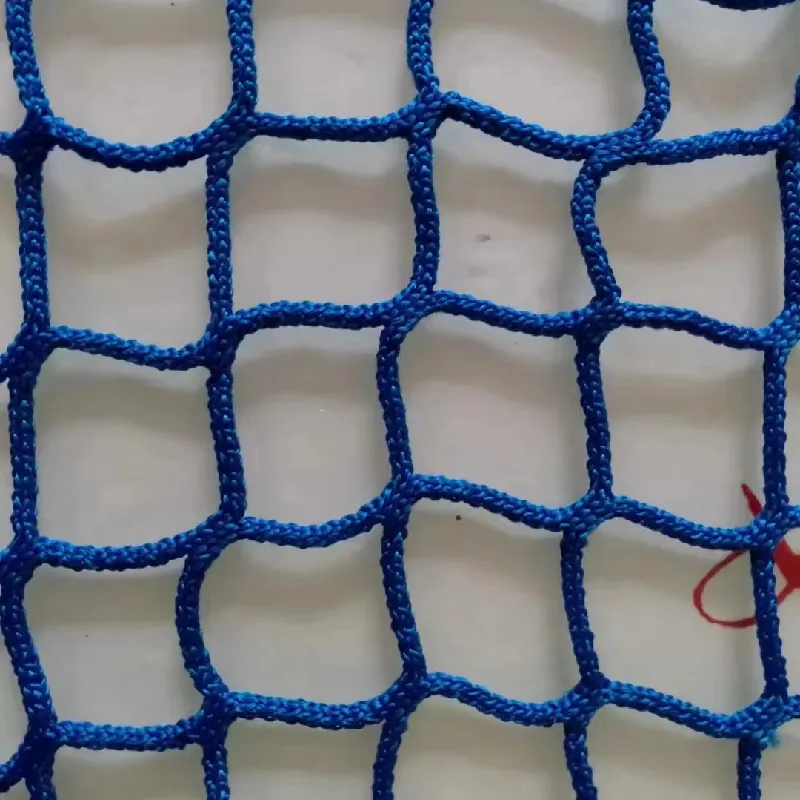

nylon filter mesh

Understanding Nylon Filter Mesh A Versatile Solution for Filtration Needs

Nylon filter mesh has become an essential component across various industries due to its remarkable properties and versatile applications. Renowned for its durability, flexibility, and resistance to chemicals, nylon mesh serves as an ideal medium for filtration processes. In this article, we will explore the characteristics, uses, and benefits of nylon filter mesh, providing insights into why it has gained such widespread popularity.

Characteristics of Nylon Filter Mesh

Nylon filter mesh is made from nylon polymer, a synthetic material known for its strength and resilience. One of the primary advantages of nylon mesh is its ability to withstand high temperatures, making it suitable for applications that involve hot liquids or gases. The mesh comes in various pore sizes, allowing for customization based on specific filtration needs. From coarse filters that capture larger particles to fine meshes capable of separating smaller contaminants, nylon mesh is available in a range of configurations.

Furthermore, nylon's inherent resistance to abrasion contributes to its long lifespan, eliminating the need for frequent replacements. This durability, combined with its lightweight nature, makes nylon filter mesh an economical choice for many businesses. Additionally, nylon mesh is often UV stabilized, which helps prevent degradation from prolonged exposure to sunlight, ensuring reliability in outdoor applications.

Applications of Nylon Filter Mesh

The applications of nylon filter mesh are numerous and varied, spanning several industries

. In the food and beverage sector, nylon mesh is frequently used in brewing, winemaking, and juice production to ensure that unwanted particles are filtered out, resulting in a cleaner final product. It is also employed in the dairy industry for separating milk from cream and in cheese production for whey separation.In the pharmaceutical and medical fields, nylon filter mesh plays a vital role in the production of sterile solutions and the preparation of various medicinal formulations. It is often used in laboratory settings for cell filtration, where precise separation of biological materials is paramount.

nylon filter mesh

Furthermore, nylon filter mesh finds utility in the automotive industry, particularly in fuel filtering systems, where it helps maintain engine efficiency and performance by preventing contaminants from entering fuel lines. Another significant application is in water treatment facilities, where nylon mesh is part of pre-filtration systems designed to remove larger particles before water undergoes more sophisticated purification processes.

Benefits of Using Nylon Filter Mesh

The benefits of nylon filter mesh are compelling. Firstly, its chemical resistance allows it to be used in environments with aggressive solvents or harsh chemicals without deteriorating. This feature expands the range of applications significantly, making it suitable for industries like painting, electroplating, and chemical processing.

Additionally, nylon mesh is easy to clean and maintain. Its adaptability means it can be washed and reused multiple times without losing its filtering capabilities, making it environmentally friendly as it reduces waste from disposable filters. Users can select from various mesh sizes and configurations tailored to their specific needs, ensuring optimal performance for the intended application.

Nylon filter mesh is also cost-effective. While it is important to consider the initial investment in quality materials, the longevity and effectiveness of nylon mesh can lead to lower overall costs in filtration processes. Businesses can rely on its consistent performance to reduce downtime and increase productivity.

Conclusion

In conclusion, nylon filter mesh stands out as a robust, flexible, and efficient solution for a wide range of filtration applications. Its durability, chemical resistance, and customizable nature make it a preferred choice across industries, from food processing to pharmaceuticals, automotive to water treatment. As industries continue to evolve and require more efficient filtration methods, the importance of nylon filter mesh is likely to grow, reaffirming its status as a fundamental component in modern filtration technology. Embracing nylon filter mesh can lead to cleaner products, improved processes, and enhanced operational efficiencies in virtually any field where filtration is essential.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025