-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

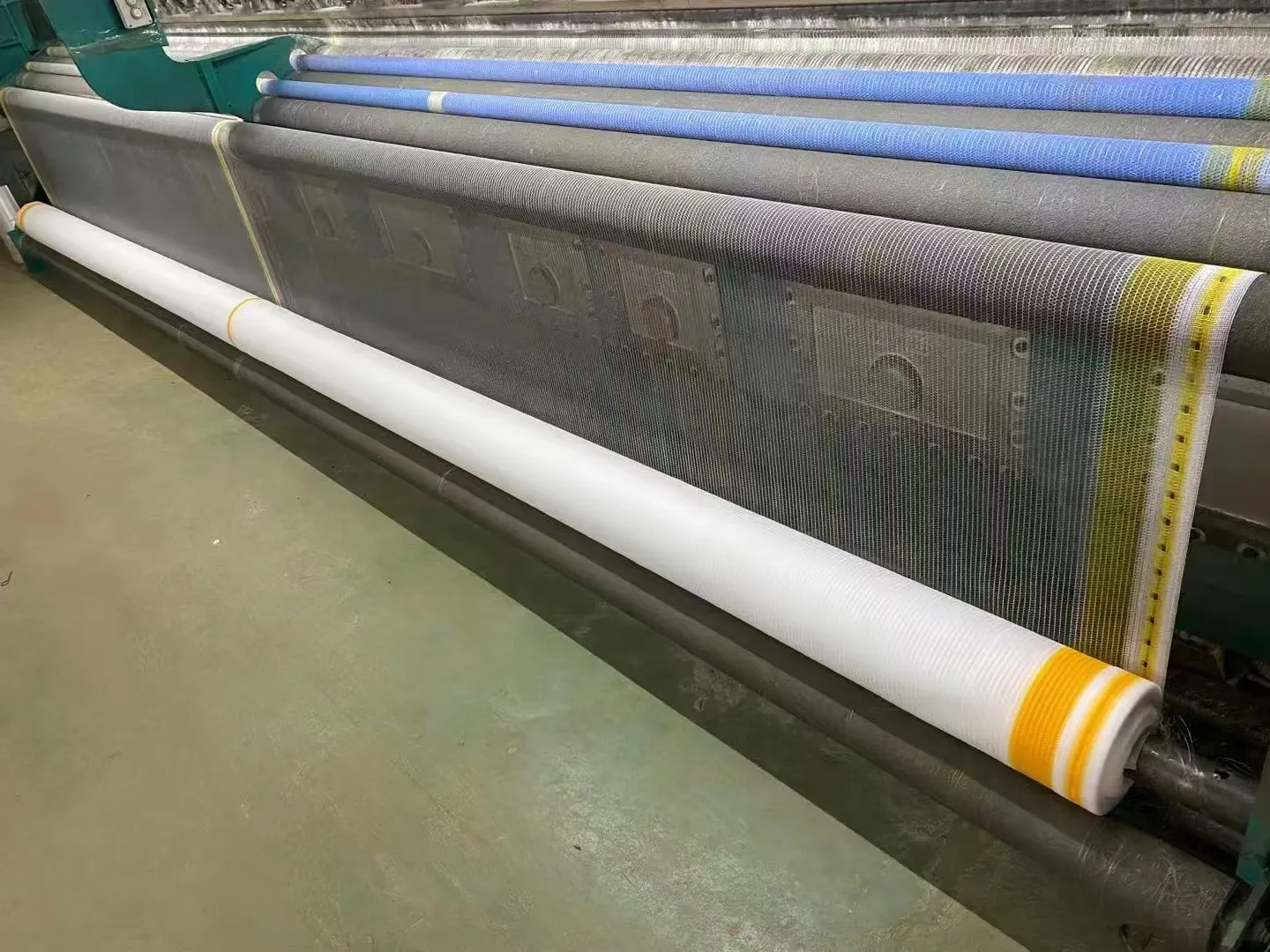

Durable Nylon Woven Mesh for Versatile Applications and Enhanced Performance

The Versatility and Applications of Nylon Woven Mesh

Nylon woven mesh is a remarkable material known for its robustness, flexibility, and diverse applications across various industries. Made from nylon, a high-strength synthetic polymer, this mesh is engineered to withstand wear and tear, making it a preferred choice for numerous applications ranging from industrial to recreational uses.

1. Understanding Nylon Woven Mesh

Nylon woven mesh is created by intertwining nylon fibers, resulting in a strong yet lightweight material that boasts excellent durability and resistance to abrasion. The weaving process can be customized to create different mesh patterns and sizes, catering to specific needs. Its porous structure allows for ventilation and fluid movement, making it an ideal material for filtering, reinforcing, or as a barrier.

2. Industrial Applications

In industrial settings, nylon woven mesh is widely utilized for filtration systems. Its fine mesh can effectively separate solids from liquids, making it an essential component in chemical processing, food and beverage manufacturing, and wastewater management. The mesh can filter out particulate contaminants while allowing liquids to pass through, ensuring purity and safety.

Moreover, nylon mesh is commonly used in the manufacturing of conveyor belts. The strength and flexibility of nylon allow the belts to withstand heavy loads and endless movement without losing form. These conveyor systems are vital in manufacturing plants, allowing for efficient transportation of materials from one station to another.

nylon woven mesh

Nylon woven mesh also finds extensive use in recreational activities. For instance, it is commonly used in the construction of outdoor equipment such as tents, bags, and fishing nets. The lightweight nature of nylon makes it easy to carry, while its durability ensures that these products can withstand harsh outdoor conditions.

Tents made with nylon mesh are often designed to be water-resistant, providing an effective barrier against rain while allowing for breathability and ventilation. Furthermore, fishing nets crafted from nylon are particularly valued for their strength, enabling them to capture various fish species without tearing.

4. Health and Safety

In the medical field, nylon woven mesh is employed in various applications, including surgical mesh and protective garments. Surgical mesh, used for hernia repairs and other procedures, benefits from nylon's strength and biocompatibility. This material allows for proper healing, reducing the risk of complications. Additionally, protective garments made from nylon mesh can provide an extra layer of safety for workers in hazardous environments, ensuring they are shielded from potential harm while maintaining comfort and mobility.

5. Environmentally Friendly Options

As environmental awareness grows, some manufacturers are exploring sustainable options for nylon woven mesh. Innovations in recycling technology have made it possible to produce nylon mesh from post-consumer waste, thereby reducing the overall environmental footprint. These eco-friendly alternatives maintain the same desirable properties of traditional nylon while promoting sustainability.

6. Conclusion

The applications of nylon woven mesh are as varied as they are valuable. From industrial filtration to recreational gear and medical uses, the versatility of this material makes it an indispensable component in numerous fields. Its strength, lightweight nature, and adaptability position nylon woven mesh as a vital resource for modern technology and practical applications. As industries continue to innovate, the demand for nylon woven mesh will likely grow, further solidifying its place in both everyday life and specialized functions. Whether for commercial or personal use, the remarkable properties of nylon woven mesh offer solutions that combine functionality with performance, continually proving its worth in a dynamic world.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025