-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 02, 2025 05:27

Back to list

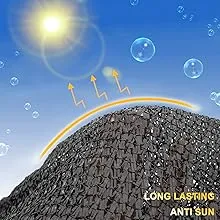

Blue insect-proof net Window screen 16✖13

Nylon woven mesh stands as a cornerstone in the realm of industrial materials and consumer goods, offering remarkable versatility and resilience. This synthetic fabric has carved its niche across various sectors, flourishing due to its inherent properties that blend performance with cost-efficiency. Delving into its capabilities and applications not only underscores its utility but also solidifies its standing as an indispensable commodity in both specialized industries and daily life.

Innovative Applications Innovations in the design and implementation of nylon woven mesh continue to surface, particularly in the green energy sector. Solar panels, for instance, integrate the mesh into their structure to enhance durability and protect the photovoltaic cells against environmental elements without obscuring sunlight. Similarly, wind turbines benefit from the mesh's application, where it acts as a protective screen ensuring safe operation while optimizing airflow around the turbine blades. Such cutting-edge uses reflect trust and reliability in this material to keep pace with evolving technological demands. Trust in Safety and Environmental Impact Nylon woven mesh's safety features are pivotal for sectors where user protection is paramount. Its non-toxic makeup ensures it poses no health risks, qualifying it as a safe choice in medical and food industries. Furthermore, efforts are ongoing to enhance the eco-friendliness of nylon production, with new advancements in recycling technologies aiming to reduce the environmental footprint associated with its synthesis. These factors collectively presage a future where nylon woven mesh usage aligns more closely with sustainable practices, asserting its trustworthiness in responsible consumption. In conclusion, nylon woven mesh is not merely a material but a benchmark of quality and performance across diverse fields. Its vibrant tapestry of properties—anchored by strength, adaptability, and chemical resilience—facilitates its role as a solution-oriented material trusted by professionals and industries worldwide. Exploring its possibilities reveals a landscape ripe with potential, reinforcing its position as a dynamic force in modern material science and industrial design. This modern marvel continues to garner attention and foster innovation, poised to evolve with technological advancements defining the future of material application.

Innovative Applications Innovations in the design and implementation of nylon woven mesh continue to surface, particularly in the green energy sector. Solar panels, for instance, integrate the mesh into their structure to enhance durability and protect the photovoltaic cells against environmental elements without obscuring sunlight. Similarly, wind turbines benefit from the mesh's application, where it acts as a protective screen ensuring safe operation while optimizing airflow around the turbine blades. Such cutting-edge uses reflect trust and reliability in this material to keep pace with evolving technological demands. Trust in Safety and Environmental Impact Nylon woven mesh's safety features are pivotal for sectors where user protection is paramount. Its non-toxic makeup ensures it poses no health risks, qualifying it as a safe choice in medical and food industries. Furthermore, efforts are ongoing to enhance the eco-friendliness of nylon production, with new advancements in recycling technologies aiming to reduce the environmental footprint associated with its synthesis. These factors collectively presage a future where nylon woven mesh usage aligns more closely with sustainable practices, asserting its trustworthiness in responsible consumption. In conclusion, nylon woven mesh is not merely a material but a benchmark of quality and performance across diverse fields. Its vibrant tapestry of properties—anchored by strength, adaptability, and chemical resilience—facilitates its role as a solution-oriented material trusted by professionals and industries worldwide. Exploring its possibilities reveals a landscape ripe with potential, reinforcing its position as a dynamic force in modern material science and industrial design. This modern marvel continues to garner attention and foster innovation, poised to evolve with technological advancements defining the future of material application.

Latest news

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025