-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

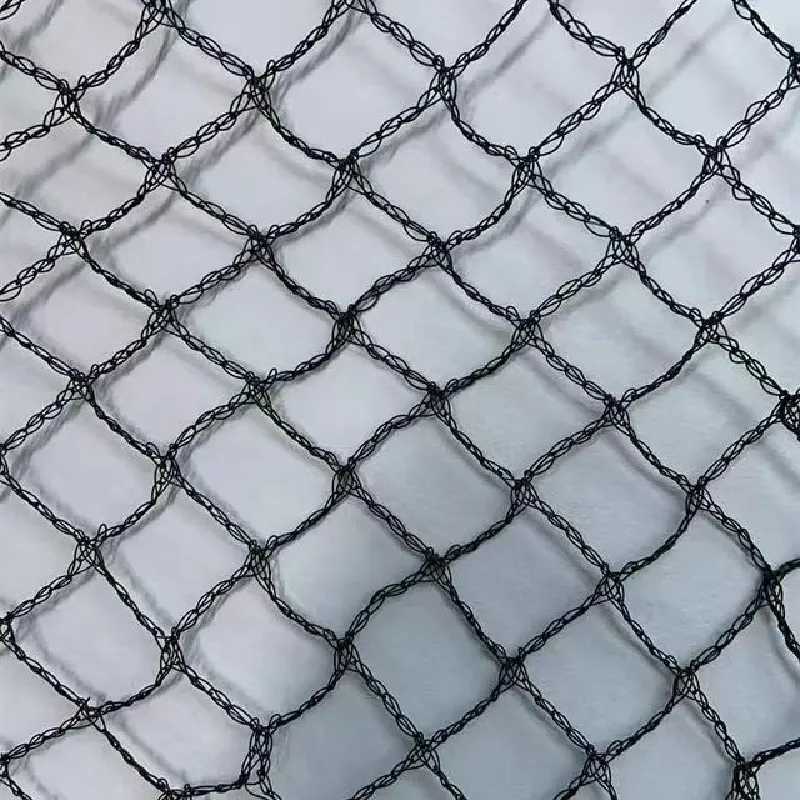

plastic mesh for plastering

The Benefits of Plastic Mesh for Plastering

In the construction and renovation industry, the materials used for plastering can significantly affect the durability and finish of a project. One innovative solution that has gained popularity in recent years is the use of plastic mesh for plastering applications. This versatile material provides a range of advantages over traditional methods and is increasingly being adopted by contractors and DIY enthusiasts alike.

Understanding Plastic Mesh

Plastic mesh, often made from polyethylene or polypropylene, is a lightweight, flexible material that can withstand the rigors of construction work. Unlike metal lath, which can corrode and rust over time, plastic mesh remains stable and unaffected by moisture. This attribute makes it particularly useful in environments where the risk of water damage is high, such as basements and bathrooms.

Key Advantages of Plastic Mesh in Plastering

1. Enhanced Durability One of the primary benefits of using plastic mesh is its exceptional durability. It is resistant to rot, corrosion, and decay, ensuring that plaster adheres securely over time. This longevity is crucial for maintaining the integrity of plaster finishes, especially in humid or wet conditions.

2. Lightweight and Easy to Handle Compared to traditional metal lath, plastic mesh is much lighter. This makes it easier to transport and install, reducing labor costs and time spent on the job. Workers can cut and shape the mesh with minimal effort, allowing for a more efficient plastering process.

3. Flexibility and Versatility Plastic mesh can be molded to fit various surface shapes and sizes, allowing for more creative design possibilities. Whether it’s for traditional walls, curved surfaces, or intricate architectural elements, plastic mesh can accommodate the unique requirements of each project.

plastic mesh for plastering

4. Cost-Effectiveness The affordability of plastic mesh compared to other plastering substrates is another significant advantage. Its durability means fewer repairs and replacements in the long run, resulting in overall cost savings for builders and homeowners.

5. Improved Adhesion The design of plastic mesh provides a rough surface that promotes better adhesion of plaster. This allows for a stronger bond between the plaster and the underlying surfaces, minimizing the risk of cracking and delamination.

6. Environmental Considerations Many plastic meshes are manufactured using recycled materials and are recyclable themselves, making them an environmentally conscious choice for sustainable building practices. This is increasingly important in a world that demands responsible sourcing and waste reduction.

Applications of Plastic Mesh

Plastic mesh can be utilized in a variety of plastering applications. It is commonly used for interior and exterior plastering work, as well as in stucco systems. Additionally, its lightweight nature makes it suitable for lightweight partition walls and other non-load-bearing applications. Whether renovating a home or constructing a new commercial building, plastic mesh provides a reliable solution for a range of plastering needs.

Conclusion

In conclusion, plastic mesh is revolutionizing the plastering process in the construction industry. Its durability, flexibility, and cost-effectiveness make it a superior choice over traditional materials. As builders and homeowners continue to seek innovative solutions that enhance the quality and longevity of their projects, the use of plastic mesh will undoubtedly continue to grow. Embracing this modern material can lead to better results and a more efficient plastering process, ultimately contributing to the overall success of construction ventures.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025