-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

plastic mesh for plastering

The Benefits of Plastic Mesh for Plastering

When it comes to construction and renovation, achieving a smooth and durable finish is crucial. One of the essentials in modern plastering techniques is the use of plastic mesh. This innovative material has gained popularity among professionals and DIY enthusiasts alike, offering numerous advantages over traditional methods. In this article, we will explore what plastic mesh is, its benefits, and how it can enhance the plastering process.

What is Plastic Mesh?

Plastic mesh, often made from high-density polyethylene (HDPE) or polypropylene, is a lightweight and flexible material that provides structural support for plastering applications. It is designed as a grid of interconnected fibers, which helps distribute tension and prevents cracking in plaster layers. Traditionally, metal lath was employed for similar purposes, but plastic mesh has emerged as a preferred alternative due to its enhanced characteristics.

Advantages of Plastic Mesh in Plastering

1. Corrosion Resistance Unlike metal lath, plastic mesh is impervious to rust and corrosion. This property is especially advantageous in environments with high moisture levels, where metal can deteriorate over time. Plastic mesh ensures that the integrity of the plaster remains intact for an extended period.

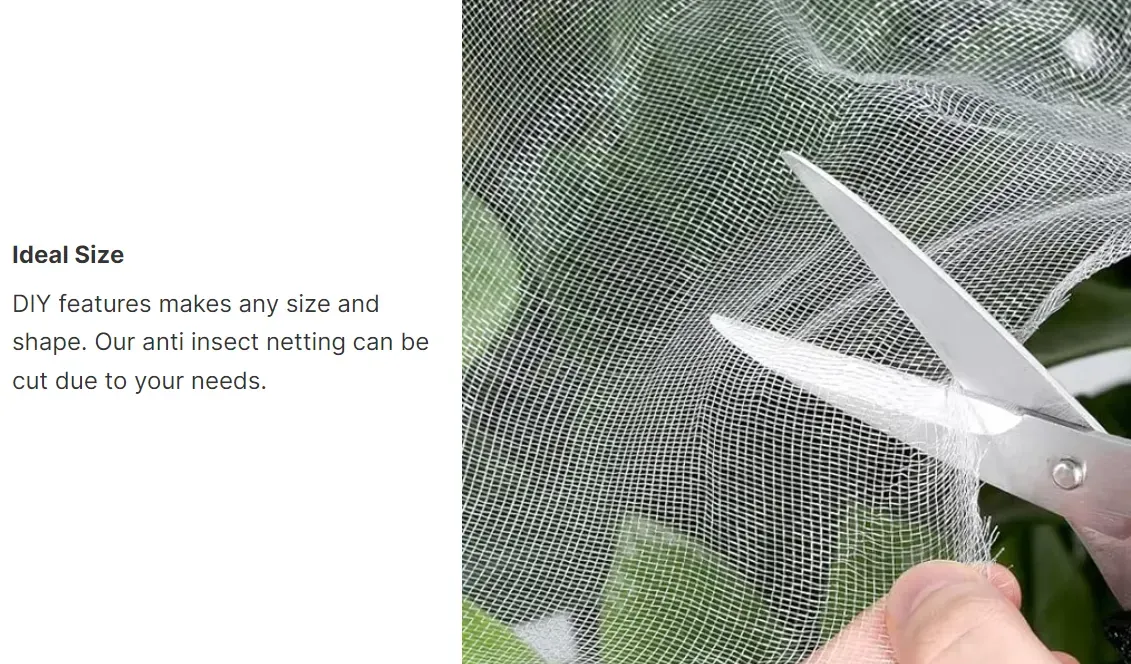

2. Lightweight and Easy to Handle Plastic mesh is considerably lighter than its metal counterparts. This lightweight nature allows for easier handling and installation, reducing the overall labor costs associated with plastering projects. Additionally, it can be cut to size and shape with basic tools, making it versatile for various applications.

3. Flexible and Durable The flexibility of plastic mesh allows it to conform to uneven surfaces, ensuring a smooth application of plaster. Furthermore, its durability means that it can withstand the stresses of settling and thermal expansion without compromising the plaster's integrity.

4. Adhesion Properties Plastic mesh provides an excellent surface for plaster to adhere to. The mesh's textured surface enhances the bonding between the plaster and the substrate, reducing the likelihood of delamination or cracking. This enhanced adhesion contributes to the longevity of the plastered surface.

5. Cost-Effectiveness The use of plastic mesh in plastering can lead to significant cost savings. Its longevity, combined with lower labor costs due to easier installation, means that projects can be completed more efficiently and economically. Moreover, its resistance to corrosion reduces maintenance and replacement costs over time.

plastic mesh for plastering

6. Environmental Considerations Many plastic meshes are made from recycled materials, making them an eco-friendly choice for construction. Their long lifespan further reduces waste, as fewer materials need to be disposed of in landfills. Choosing plastic mesh aligns with sustainable building practices that prioritize environmental impact.

Applications of Plastic Mesh in Plastering

Plastic mesh is suitable for a wide range of plastering applications. It is commonly used in

- Exterior Insulation and Finish Systems (EIFS) Plastic mesh provides reinforcement for exterior finishes, helping to prevent cracking due to weather-related stress.

- Stucco Applications In traditional stucco work, plastic mesh serves as a base to ensure that the stucco adheres properly to the wall surface, resulting in a long-lasting finish.

- Interior Plastering For indoor projects, plastic mesh can be used to reinforce plaster on drywall or other surfaces, ensuring a robust and aesthetically pleasing finish.

- Renovation Projects When renovating older buildings, plastic mesh can be a valuable tool for providing additional support to existing plaster, improving the overall stability and appearance of the walls.

Conclusion

Plastic mesh has revolutionized the plastering industry by offering a reliable, cost-effective, and environmentally friendly solution for various applications. Its numerous advantages over traditional materials make it a preferable choice for both professionals and DIY enthusiasts. By incorporating plastic mesh into plastering projects, one can achieve a durable, long-lasting finish that stands the test of time. As the construction industry continues to evolve, plastic mesh will undoubtedly play a significant role in shaping the future of plastering techniques. Whether for new builds or renovation projects, the benefits of plastic mesh make it an essential component in modern plastering practices.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025